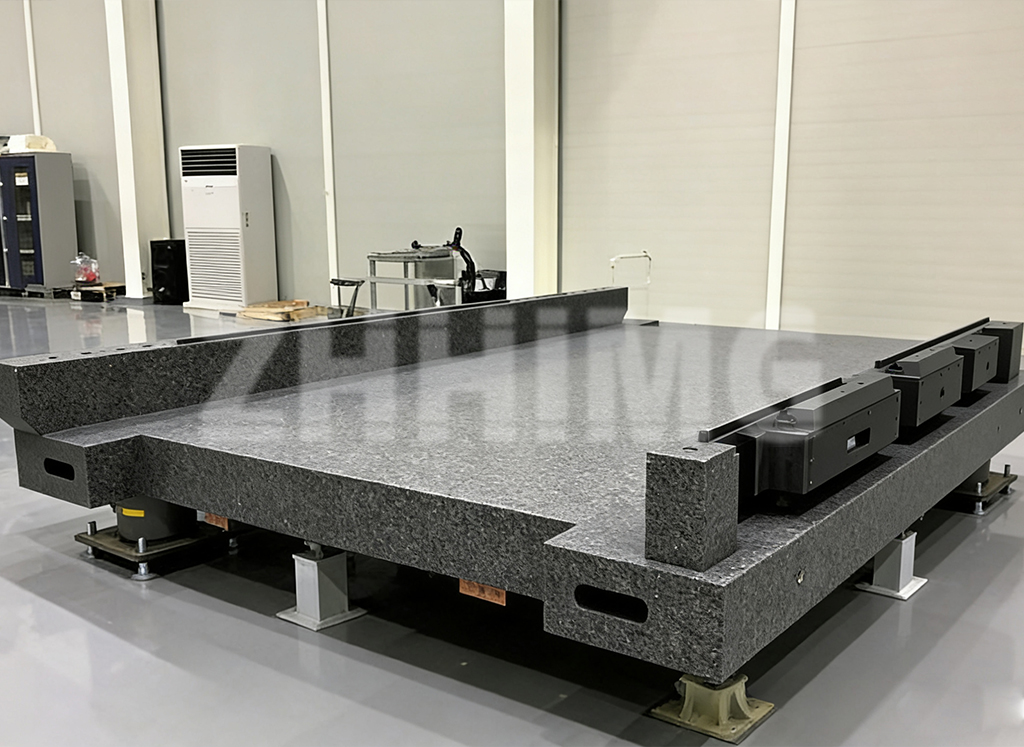

In the pursuit of higher throughput and smaller feature sizes, the modern manufacturing floor has become a battlefield of microscopic forces. Whether it is the regenerative chatter of a high-speed spindle or the micro-oscillations of a 5G-enabled linear motor, vibration is the primary enemy of accuracy. As we navigate the technical demands of 2026, the consensus among global precision linear stage manufacturers has become clear: the foundation of the machine must be “dead.” At ZHHIMG, our research into natural Black Jinan Granite confirms that this material remains the most effective energy dissipator for the world’s most sensitive industrial processes.

The Science of Silence: Why Granite Outperforms Metal

To understand why a granite CMM or lithography base is superior to cast iron, one must look at the damping coefficient—specifically the logarithmic decrement. Metals, due to their homogeneous crystalline structure, allow kinetic energy to travel relatively unimpeded, leading to “ringing” or resonance. This resonance can destroy the resolution of an optical encoder or leave visible artifacts on a diamond-turned surface.

Natural granite acts as a multi-phase composite created by the earth. Its complex mixture of minerals provides high internal friction at the molecular level. When energy enters a ZHHIMG granite base, it is not reflected; it is absorbed and converted into negligible amounts of heat. This passive damping is essential for high-dynamic motion systems where fast settling times are required to maintain high OEE (Overall Equipment Effectiveness).

Granite vs. Ceramic: Choosing the Foundation for the Nanoscale

In the highest tiers of the semiconductor industry, a new debate has emerged: Granite vs. Ceramic. While both materials offer excellent thermal stability, they serve different strategic purposes in machine design.

Precision Granite Bases:

-

Vibration Damping: Superior internal damping compared to ceramics.

-

Scale: Granite can be processed into massive monolithic structures (up to 12 meters) that are impossible or cost-prohibitive in ceramic.

-

Cost-Efficiency: Offers the best performance-to-price ratio for large-format inspection and machining centers.

Advanced Ceramic Bases (Alumina/SiC):

-

Stiffness-to-Weight: Ceramics offer higher Young’s Modulus and lower mass, making them ideal for ultra-high-acceleration “bridge” components.

-

Thermal Conductivity: Ceramics respond faster to temperature control systems, which is critical in certain vacuum-based lithography processes.

-

Size Constraints: Due to firing shrinkage and manufacturing complexity, large ceramic bases are significantly more expensive and difficult to produce than their granite counterparts.

At ZHHIMG, we often recommend a hybrid approach. Using a massive granite base for its damping and thermal inertia, paired with ceramic or carbon-fiber moving components, allows manufacturers to achieve the “Holy Grail” of precision: high speed without the penalty of residual vibration.

The ZHHIMG Advantage: Precision Machining of the Eternal Material

Being a premier partner for precision linear stage manufacturers requires more than just raw stone. It requires the ability to turn a geological artifact into a mechanical component with sub-micron tolerances. Our constant-temperature workshops ensure that the granite is machined and lapped in the same environment it will eventually inhabit.

One of the most significant challenges in granite engineering is the integration of mechanical interfaces. ZHHIMG has mastered the art of “blind-hole” drilling and epoxy-bonding stainless steel inserts that can withstand the high-torque requirements of modern linear motors. This ensures that the “soft” damping of the stone is perfectly coupled with the “hard” rigidity of the motion system.

Conclusion: Stability for the Next Industrial Revolution

As we look toward the future of nanotechnology and aerospace metrology, the “passive” role of the machine base is becoming increasingly active. A ZHHIMG granite base does not just hold the machine; it enables the machine to perform at its theoretical limit. By selecting the right grade of granite and understanding the nuances of vibration damping, engineers can build systems that are faster, quieter, and fundamentally more accurate.

ZHHIMG remains dedicated to being the solid foundation upon which the world’s most precise technologies are built.

Post time: Feb-04-2026