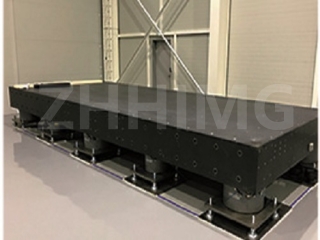

The Granite precision platform is a highly sought-after product in the field of manufacturing, particularly in industries that require ultra-high precision in their operations. It is known for its exceptional stability, accuracy, and durability, making it a preferred choice among engineers and production managers. However, even with its remarkable qualities, the Granite precision platform is not immune to defects. In this article, we will discuss some of the common defects observed in Granite precision platforms.

One of the most prevalent defects of Granite precision platforms is warping. Despite being made of granite, which is supposed to be highly stable and robust, the platform can warp when subjected to extreme temperature changes or pressure. This warping can cause significant disruptions in manufacturing operations and affect the quality of the products being produced.

Another defect is the presence of fissures or cracks on the surface of the platform. While granite is known to be a durable material, it is still susceptible to cracking, particularly if it experiences significant impact or excessive pressure. These cracks can compromise the stability and accuracy of the platform, leading to sub-optimal manufacturing outcomes.

Another defect that can affect the performance of the Granite precision platform is wear and tear. Over time, the continuous use of the platform can cause it to experience wear and tear, leading to a reduction in its precision and accuracy. While this may not be an immediate concern, it can affect the long-term productivity of the manufacturing operation and result in significant costs for the company.

Finally, one of the most significant defects of Granite precision platforms is their price. The high cost of acquiring and maintaining these platforms can be a considerable barrier to entry for small and medium-sized companies. It limits their ability to invest in the technology required to achieve high levels of precision in their operations.

Despite the defects identified above, it is important to note that Granite precision platforms continue to be an essential component in many manufacturing operations. While it may not be perfect, it represents a significant advancement in technology and has helped companies achieve unprecedented levels of precision and accuracy in their production processes. As such, it is important for companies to weigh the benefits and drawbacks of the Granite precision platform carefully before deciding whether it is the right fit for their operations.

Post time: Jan-29-2024