In a laboratory or factory, how does an ordinary piece of granite become a "magic tool" for measuring micron-level accuracy? Behind this lies a strict quality assurance system, just like casting a "precision magic" on the stone. Today, let's uncover the quality secrets of granite measuring tools and see how they transform from rocks in the mountains into precisely manufactured "rulers".

First, good tools must have "good material stones" : the inherent advantages of granite

The quality of granite measuring tools primarily depends on their "origin". High-quality granite possesses three core characteristics:

Strong hardness: The quartz crystals in granite (accounting for over 25%) are like countless small blades, making its hardness reach 6-7 on the Mohs scale, which is even more wear-resistant than steel.

Stable performance: Ordinary metals "expand" when heated, but the coefficient of thermal expansion of granite is extremely low. Even if the temperature of ZHHIMG® 's black granite rises by 10℃, the deformation is only 5 microns - equivalent to one-tenth of the diameter of a human hair, which does not affect the measurement accuracy at all.

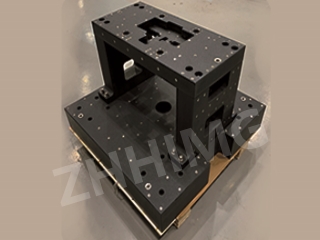

Dense structure: Good granite has a density exceeding 3000kg/m³, with almost no voids inside, just like sand is tightly bonded together with cement. The product density of ZHHIMG® reaches 3100kg/m³, and it can steadily withstand a weight of several hundred kilograms without deformation.

Ii. From Rocks to Tools: The Path of Cultivation with Micron-level Precision

For the granite mined to be turned into a measuring tool, it has to go through multiple layers of "refinement" :

Rough machining: Remove the edges and corners

Cut the granite into large pieces with a diamond saw, just like sharpening a pencil. At this point, ultrasonic waves will be used to perform a "B-ultrasound" on the stone to check for any cracks inside and ensure the integrity of the material.

Fine grinding: Grind until as flat as a mirror

The most crucial step is grinding. The grinding machine used by ZHHIMG® costs over 5 million yuan per unit and can grind the surface of granite to an astonishing precision.

Rough grinding: First, remove the rough surface layer to ensure that the height difference within a 1-meter length does not exceed 5 microns.

Fine grinding: Then polished with ultrafine grinding powder, and the final flatness reaches ±0.5 microns /m

A "training ground" with constant temperature and humidity

Grinding must be carried out in a special workshop: the temperature is maintained at around 20℃, the humidity is stabilized at 50%, and a 2-meter-deep shock-proof trench must be dug to prevent outside vehicles from passing by and affecting the accuracy. Just like athletes can only perform at their best when training in a constant-temperature swimming pool.

Iii. Quality Assurance: Multiple layers of inspection and control

Before each granite tool leaves the factory, it must undergo "strict control" :

Measuring height with a minute gauge: The German Mahr minute gauge can detect an error of 0.5 microns, which is even smaller than the thickness of a mosquito's wing. It is used to check whether the surface of a tool is flat.

Laser interferometer mirror: Take a "photo" of the tool surface with a laser to see if there are any subtle undulations. The products of ZHHIMG® need to pass three tests, and each time they must be left to stand in a constant-temperature room for 24 hours to ensure that the temperature does not affect the results.

A certificate is like an "ID card" : Each tool has a "birth certificate" - a calibration certificate, which records over 20 pieces of precision data. By scanning the code, you can access its "growth profile".

Iv. International Certification: The Global Pass to Quality

ISO certification is like the "academic certificate" of granite tools:

ISO 9001: Ensure that each batch of materials is of equal quality, just like apples in a supermarket, with each size having approximately the same sweetness level;

ISO 14001: The processing procedure should be environmentally friendly and not pollute the environment. For example, the generated dust should be treated thoroughly.

ISO 45001: The working environment for workers should be good. For example, the noise in the workshop should not be too loud so that they can concentrate on making good tools.

In high-end fields such as semiconductors, more rigorous certifications are still needed. For instance, when ZHHIMG® products are used for chip testing, they must obtain SEMI certification to ensure that no tiny particles are released on the surface, so as to avoid contaminating the precise chips.

V. Speak with Data: The Practical Benefits Brought by Quality

Good granite measuring tools can bring about astonishing results:

After a PCB factory adopted the ZHHIMG® platform, the scrap rate dropped by 82% and it saved 430,000 yuan in a year.

When inspecting 5G chips, high-precision granite tools can identify defects as small as 1 micron - equivalent to finding a grain of sand on a football field.

From the rocks in the mountains to the measuring tools in the precision laboratory, the transformation path of granite is filled with science and craftsmanship. Every quality indicator and every precise inspection is aimed at making this stone the "cornerstone" that drives technological progress. Next time you see a granite measuring tool, don't forget the strict quality code behind it!

Post time: Jun-18-2025