In the modern industrial landscape, where the difference between a high-performance aerospace component and a critical failure is measured in nanometers, the structural integrity of measurement systems is non-negotiable. As engineers and quality laboratory managers evaluate the next generation of metrology equipment, the debate often returns to a fundamental question: What material should form the foundation of precision?

At ZHHIMG, we specialize in the engineering of high-stability platforms. Understanding the nuanced differences between a granite machine base and a cast iron machine base is essential for any facility aiming for sub-micron repeatability.

The Physical Imperative: Why Material Choice Matters

Every Coordinate Measuring Machine (CMM) and Universal Length Measuring Instrument (ULMI) is subject to the laws of thermodynamics and classical mechanics. The base of these instruments must fulfill three primary roles: thermal dampening, vibration absorption, and long-term dimensional stability.

Granite vs. Cast Iron: A Comparative Analysis

For decades, cast iron machine bases were the backbone of the toolroom. While cast iron offers high rigidity and can be cast into complex internal geometries, it is inherently limited by its metallic nature.

-

Thermal Expansion: The coefficient of thermal expansion for cast iron is roughly double that of natural black granite. In a laboratory where temperature control might fluctuate by 0.5°C, a cast iron base will expand and contract significantly more than a granite machine base, introducing “ghost errors” into the measurement data.

-

Vibration Damping: While cast iron has better damping than steel, it cannot match the internal crystalline structure of granite. Granite’s natural composition acts as a superior buffer against the high-frequency micro-vibrations common in modern manufacturing environments.

-

Magnetic Neutrality and Corrosion: Unlike metallic bases, a precision surface plate or machine base made of granite is naturally non-conductive and non-magnetic. It does not rust, meaning it requires no protective oils that could potentially contaminate sensitive optical comparators or laser scales.

CMM and ULMI: Different Instruments, One Foundation

While the materials provide the stability, the application dictates the form. We often see a strategic divide in how laboratories deploy their hardware.

The Versatility of the Coordinate Measuring Machine (CMM)

The CMM is the universal translator of the manufacturing world. By moving a probe across three axes, it creates a digital twin of a physical part. Because the bridge of a CMM moves dynamically, the mass and damping of the granite machine base are critical to prevent inertial lag. For high-speed CMMs, ZHHIMG engineers the base to ensure that the center of gravity remains low, minimizing the “rocking” effect during rapid acceleration.

The Precision of the Universal Length Measuring Instrument (ULMI)

Where a CMM provides 3D versatility, a Universal Length Measuring Instrument provides 1D and 2D certainty. Often used for calibrating master gauges, the ULMI requires a base with near-zero internal stress. Any microscopic warping of the base over time would render the instrument useless for calibration. This is why the world’s most accurate ULMIs almost exclusively utilize aged, stress-relieved granite components.

Mitigating Environmental Noise

Even the highest quality metrology equipment can be compromised by its surroundings. A heavy press operating 50 meters away or a forklift moving through a warehouse can send seismic waves through the floor.

To counteract this, a vibration isolation table is no longer a luxury—it is a necessity. By integrating the machine base with active or passive pneumatic isolation, ZHHIMG ensures that the measurement envelope remains isolated from the “seismic noise” of the factory. This synergy between a high-mass granite base and a responsive isolation system is what allows for the achievement of Grade 000 tolerances.

The ZHHIMG Advantage in Material Engineering

Our approach to manufacturing transcends simple stone cutting. We view the production of a precision surface plate or a custom machine bed as a multi-stage scientific process:

-

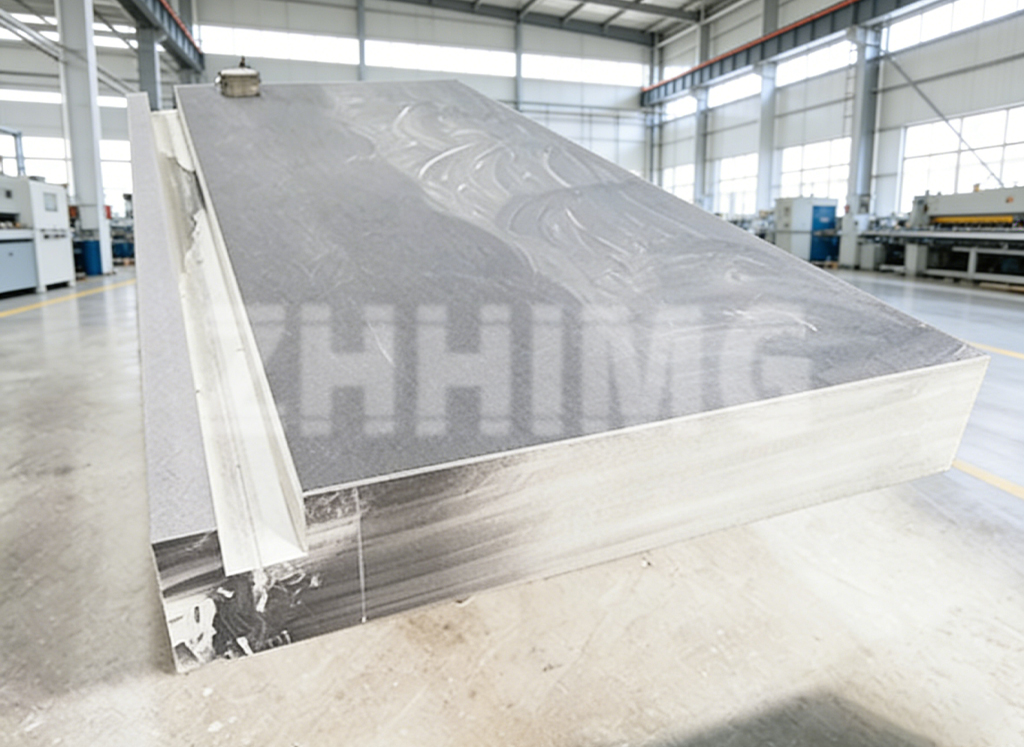

Geological Selection: Not all granite is equal. We select gabbro-diabase for its specific density and low water absorption.

-

Precision Lapping: Our technicians utilize hand-lapping techniques that no CNC machine can replicate, achieving flatness levels that meet and exceed international standards.

-

System Integration: We provide a holistic ecosystem, from the initial cast iron machine base for heavy industrial use to the ultra-refined granite structures for semiconductor inspection.

Strategic Conclusion for High-Precision Facilities

Choosing between materials and instrument types is a balance of application, environment, and required uncertainty. While cast iron still holds a place in heavy-duty machining centers, the metrology world has decisively moved toward the stability of granite and the advanced damping of mineral casting.

Investing in a ZHHIMG foundation ensures that your metrology equipment—whether it is an optical comparator or a multi-axis CMM—operates in an environment of absolute stability. In the pursuit of precision, the base is not just a part of the machine; it is the most important component of the measurement.

Post time: Jan-29-2026