As machine tools evolve toward higher spindle speeds and greater acceleration, the limitations of traditional grey cast iron and welded steel structures have become a significant bottleneck. In the quest for superior surface finishes and longer tool life, the industry is increasingly turning to advanced composite materials. Specifically, the properties of polymer concrete—often referred to as mineral casting—are redefining the structural foundations of high-precision equipment.

At ZHHIMG, we have observed a decisive shift among European and American OEMs who are moving away from metallic frames in favor of mineral-based solutions. This transition is driven by a fundamental need for better dynamic behavior and thermal equilibrium in the manufacturing environment.

The Science of Stability: Vibration Damping Materials for Machine Tools

In any high-precision machining operation, vibration is the primary enemy of accuracy. Whether it is the regenerative chatter of a milling cutter or the micro-oscillations of a linear motor, vibration degrades tool life and surface quality. This is where the choice of vibration damping materials for machine tools becomes critical.

Polymer concrete consists of a precisely calibrated mixture of mineral aggregates—such as quartz, basalt, and granite—bonded together by a high-performance epoxy resin system. Unlike the crystalline structure of metals, which allows vibration to travel relatively unimpeded, the multi-phase composite structure of mineral casting acts as a natural energy dissipator.

Studies indicate that polymer concrete has a damping capacity approximately 6 to 10 times higher than that of grey cast iron. This high logarithmic decrement means that vibrations induced by the cutting process are absorbed almost instantly, allowing for higher gain settings in the drive controllers and ultimately resulting in a more productive machine.

Deciphering the Manufacturing Process of Mineral Casting

A significant advantage of mineral casting lies in its “Cold Casting” manufacturing philosophy. Unlike cast iron, which requires high-energy furnaces and involves significant shrinkage during cooling, the manufacturing process of mineral casting occurs at or near room temperature.

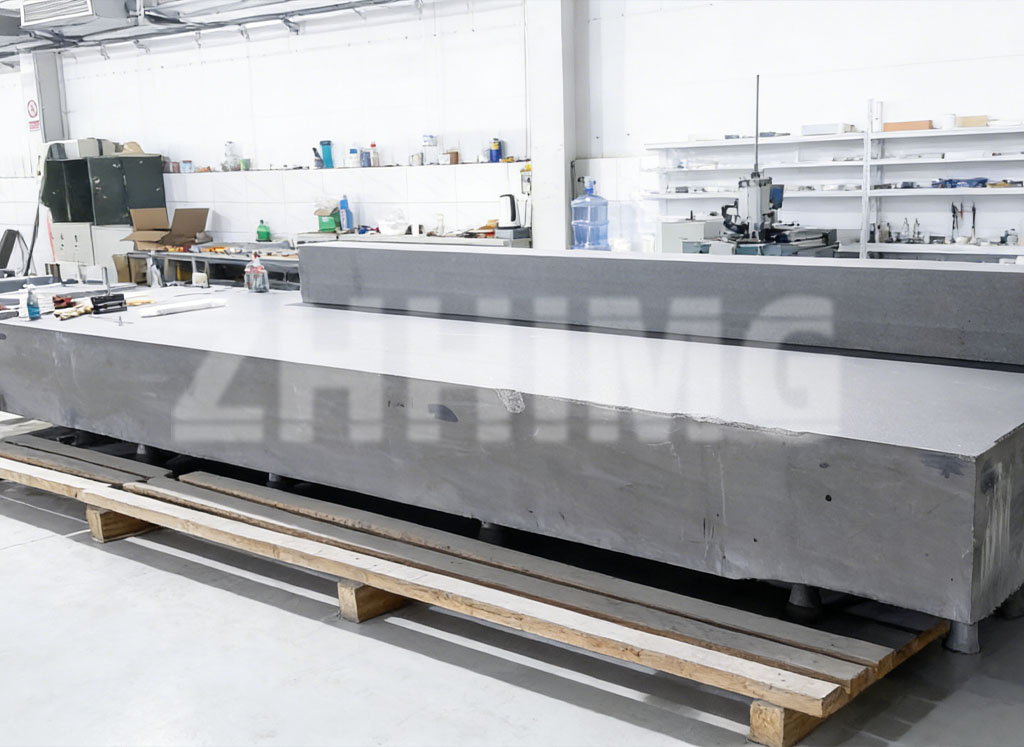

The process begins with the preparation of a precision mold, often made of steel or wood, depending on the production volume. ZHHIMG utilizes advanced simulation software to determine the optimal aggregate distribution, ensuring there are no voids within the structure. The epoxy resin and hardener are mixed with the dried mineral components and poured into the mold.

One of the most valuable aspects of this process is the ability to integrate functional components directly into the casting. Threaded inserts, leveling elements, cooling pipes, and even cable conduits can be cast in situ with extreme positional accuracy. This “one-step” integration significantly reduces the need for subsequent machining and assembly, providing a “Plug-and-Play” base for machine builders.

Thermal Inertia and Environmental Resilience

Beyond vibration, thermal displacement is a leading cause of geometric errors in machine tools. The properties of polymer concrete include a low coefficient of thermal conductivity and high specific heat capacity. In practical terms, this means that mineral casting machine bases are highly resistant to short-term temperature fluctuations in the shop floor environment.

While a steel frame might expand or warp quickly when exposed to a draft or a warm coolant splash, a mineral casting base reacts with immense “thermal inertia.” It maintains its geometric integrity over long production cycles, ensuring that the first part of the day is as accurate as the last. Furthermore, polymer concrete is essentially inert; it is resistant to most common industrial coolants, oils, and chemicals, preventing the long-term degradation often seen in metallic structures.

Sustainability and the Circular Economy

In today’s global market, the environmental footprint of manufacturing is under intense scrutiny. The production of mineral casting is significantly more energy-efficient than that of cast iron. It requires no melting of ore and generates substantially lower CO2 emissions. Moreover, at the end of a machine’s lifecycle, polymer concrete bases can be crushed and reused as high-quality aggregate for construction or new machine bases, supporting a circular economy.

Partnering with ZHHIMG for Mineral Excellence

ZHHIMG Group stands at the intersection of material science and mechanical engineering. Our expertise in both precision granite and mineral casting allows us to provide the most objective structural advice for your specific application. From the initial design-for-casting phase to the final high-precision grinding of mounting surfaces, we ensure that your machine foundation is built for the demands of the 21st century.

As the industry moves toward “Industry 4.0″ and autonomous manufacturing, the demand for stable, damped, and thermally neutral machine structures will only intensify. Polymer concrete is not just a material of the future; it is the material of the present for those who demand excellence.

Post time: Feb-02-2026