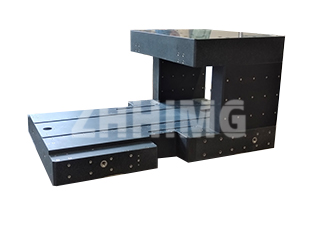

The precision granite testing platform is the foundation of repeatable, accurate measurement. Before any granite tool—from a simple surface plate to a complex square—is deemed fit for use, its accuracy must be rigorously verified. Manufacturers like ZHONGHUI Group (ZHHIMG) adhere to strict quality control standards, certifying platforms across grades such as 000, 00, 0, and 1. This certification relies on established, technical methods that define the surface’s true flatness.

Determining Flatness: The Core Methodologies

The core objective of certifying a granite platform is to determine its flatness error (FE). This error is fundamentally defined as the minimal distance between two parallel planes that contain all points of the actual working surface. Metrologists employ four recognized methodologies to determine this value:

The Three-Point and Diagonal Methods: These methods offer practical, foundational assessments of the surface topography. The Three-Point Method establishes the evaluation reference plane by selecting three widely separated points on the surface, defining the FE by the distance between the two enclosing parallel planes. The Diagonal Method, often employed as the industry standard, typically utilizes sophisticated tools like an electronic level in conjunction with a bridge plate. Here, the reference plane is set along a diagonal, offering an efficient way to capture the overall error distribution across the entire surface.

The Smallest Multiplier Two (Least Squares) Method: This is the most mathematically rigorous approach. It defines the reference plane as the one that minimizes the sum of the squares of the distances from all measured points to the plane itself. This statistical method provides the most objective assessment of flatness but requires advanced computer processing due to the complexity of the calculations involved.

The Small Area Method: This technique directly conforms to the geometric definition of flatness, where the error value is determined by the width of the smallest area necessary to encompass all measured surface points.

Mastering Parallelism: The Dial Indicator Protocol

Beyond basic flatness, specialized tools like granite squares require verification of parallelism between their working faces. The dial indicator method is highly suited for this task, but its reliability hinges entirely on meticulous execution.

The inspection must always be performed on a high-accuracy reference surface plate, utilizing one measuring face of the granite square as the initial reference, carefully aligned against the platform. The critical step is establishing the measurement points on the face under inspection—these are not random. To ensure a comprehensive evaluation, a checkpoint is mandated approximately 5mm from the edge of the surface, complemented by an evenly spaced grid pattern across the middle, with points typically separated by 20mm to 50mm. This rigorous grid ensures that every contour is systematically mapped by the indicator.

Crucially, when inspecting the corresponding opposite face, the granite square must be rotated 180 degrees. This transition requires extreme care. The tool must never be slid across the reference plate; it must be lifted carefully and repositioned. This essential handling protocol prevents abrasive contact between the two precision-lapped surfaces, safeguarding the hard-earned accuracy of both the square and the reference platform for the long term.

Achieving the tight tolerances of higher-grade tools—like ZHHIMG’s precision-lapped Grade 00 squares—is a testament to both the superior physical properties of the granite source and the application of these strict, established metrology protocols.

Post time: Nov-03-2025