In the field of precision manufacturing, the accuracy of a tool measuring instrument directly determines the quality and efficiency of tool processing, and the material selection of its core components is a key factor affecting performance. ZHHIMG granite components, with their unparalleled technical advantages and strict quality control, have become the ideal choice for the manufacturing of tool measuring instruments, providing stable and reliable guarantees for precise measurements.

Ultimate stability, resistant to environmental interference

ZHHIMG granite components are derived from natural high-quality stone, with compact internal mineral crystallization and a dense and uniform structure. Its coefficient of thermal expansion is extremely low, only 5-7×10⁻⁶/℃, and is almost unaffected by temperature changes. During the operation of the tool measuring instrument, whether it is the heat generated by the equipment itself or the temperature fluctuations in the workshop environment, the ZHHIMG granite components can always maintain a stable size and shape, avoiding the deviation of the measurement reference caused by thermal deformation. Meanwhile, the excellent vibration damping characteristics of granite can effectively absorb external vibration interference and minimize its impact on the tool measuring instrument. Even in the complex workshop environment where machine tools are roaring and equipment is frequently started and stopped, the stable operation of the tool measuring instrument can be ensured, making the measurement data accurate and reliable.

Ultra-high precision, achieving precise measurement

Through advanced ultra-precision processing techniques, ZHHIMG conducts fine grinding and polishing of granite components, achieving a surface flatness of ±0.001mm/m or even higher levels. This ultimate precision provides a perfect measurement reference surface for the tool measuring instrument. When measuring the geometric parameters of cutting tools, high-precision granite components can ensure that the probe closely adheres to the surface of the cutting tool, accurately capturing every subtle contour change and keeping the measurement error within a very small range. Whether it is a tiny end milling cutter or a large gear cutting tool, ZHHIMG granite components can help the tool measuring instrument achieve high-precision measurement at the micrometer or even nanometer level, meeting the strict requirements of high-end manufacturing for tool accuracy.

Durable and long-lasting, reducing maintenance costs

Granite has a Mohs hardness of up to 6-7, endowing ZHHIMG components with extremely strong wear resistance. During the long-term and frequent use of the tool measuring instrument, the tool constantly comes into contact and rubs against the surface of the component. Ordinary materials may suffer from wear and scratches, which will affect the measurement accuracy. The ZHHIMG granite components, with their hard texture, can effectively resist wear and maintain surface accuracy for a long time. After practical verification, the maintenance cycle of the tool measuring instrument using ZHHIMG granite components has been significantly extended, and the maintenance cost has been greatly reduced, saving a large amount of time and capital investment for enterprises and improving production efficiency.

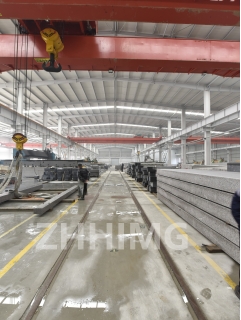

Strict quality control ensures consistent quality

ZHHIMG has always adhered to a strict quality management concept in the production process. From the meticulous screening of raw granite ore, to the full-process monitoring of the processing, and then to the strict inspection of the finished products, every link has undergone multiple layers of quality control. By adopting the world's leading testing equipment and technology, comprehensive tests are conducted on multiple indicators such as dimensional accuracy, flatness and hardness of components to ensure that each product meets or exceeds industry standards. It is precisely this unwavering pursuit of quality that makes ZHHIMG granite components the trusted choice of many precision manufacturing enterprises.

On the track of precision manufacturing, ZHHIMG granite components, with their outstanding performance, ultra-high precision and reliable quality, inject strong impetus into tool measuring instruments, helping enterprises stand out in the high-end manufacturing field and leading the industry towards a future of higher precision and higher efficiency.

Post time: May-12-2025