Granite Parallel Gauge

This granite parallel gauge is made from high-quality “Jinan Green” natural stone, machined and finely ground. It features a glossy black appearance, a fine and uniform texture, and excellent overall stability and strength. Its high hardness and excellent wear resistance allow it to maintain high precision and resist deformation even under heavy loads and at room temperature. It is also rust-resistant, acid- and alkali-resistant, and non-magnetic, making it suitable for long-term use.

It is primarily used to inspect the straightness and flatness of workpieces, as well as the geometric accuracy of machine tool tables and guideways. It can also replace contour blocks.

Physical Properties: Specific Gravity 2970-3070 kg/m2; Compressive Strength 245-254 N/m2; High Abrasiveness 1.27-1.47 N/m2; Linear Expansion Coefficient 4.6 × 10⁻⁶/°C; Water Absorption 0.13%; Shore Hardness HS70 or higher. Even if impacted during use, it will only slightly dislodge particles, without affecting overall accuracy. Our company’s granite straightedges maintain their accuracy even after prolonged periods of static use.

Granite Straightedges

Granite straightedges are primarily used for checking workpiece straightness and flatness. They can also be used for geometric verification of machine tool guideways, worktables, and equipment during installation. They play an important role in both production workshops and laboratory measurements.

Granite, primarily composed of pyroxene, plagioclase, and a small amount of olivine, undergoes long-term natural aging to eliminate internal stresses. This material offers advantages such as uniform texture, high hardness, and resistance to deformation. They maintain stable measurement accuracy even under heavy loads.

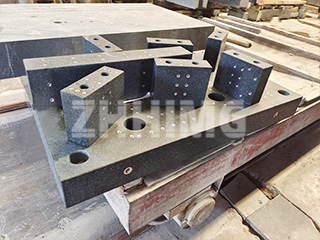

Granite Squares

Granite squares are widely used in workpiece inspection, marking, installation and commissioning, and industrial engineering construction.

They are also made from “Jinan Green” natural granite. After processing and fine grinding, they exhibit a black luster and a dense structure, characterized by high strength, hardness, and excellent stability. They are acid and alkali resistant, rust-resistant, non-magnetic, and non-deformable, and can maintain high accuracy under heavy loads and at room temperature. Physical Parameters: Specific Gravity 2970-3070 kg/m2; Compressive Strength 245-254 N/m2; High Abrasive Load 1.27-1.47 N/m2; Linear Expansion Coefficient 4.6 × 10⁻⁶/°C; Water Absorption 0.13%; Shore Hardness HS70 or above.

Granite Square

Granite squares are primarily used to check the perpendicularity and parallelism of workpieces and can also serve as a 90° measurement reference.

Crafted from high-quality “Jinan Blue” stone, they feature high gloss, uniform internal structure, excellent rigidity, and resistance to wear. They maintain geometric accuracy at room temperature and under high loads, are rust-resistant, non-magnetic, and acid- and alkali-resistant. They are widely used in inspection and measurement applications.

Comprehensive Features of Granite Precision Measuring Tools

Accuracy Grades: Grade 0, Grade 1, Grade 2

Product Color: Black

Standard Packaging: Wooden Box

Key Advantages

Natural rock undergoes long-term aging, resulting in a stable structure, low expansion coefficient, and virtually no internal stress, making it resistant to deformation and ensuring high precision.

It features a dense structure, high hardness, excellent rigidity, and superior wear resistance.

It is rust-proof, acid- and alkali-resistant, requires no oiling, and is dust-resistant, making daily maintenance simple.

It is scratch-resistant and maintains measurement accuracy even at room temperature.

It is non-magnetic, allowing for smooth movement without any lag or sticking during use, and is unaffected by humidity.

Post time: Sep-04-2025