When purchasing marble platforms or slabs, you may often hear the terms A-grade, B-grade, and C-grade materials. Many people mistakenly associate these classifications with radiation levels. In reality, that is a misunderstanding. Modern architectural and industrial marble materials used on the market today are completely safe and free of radiation. The grading system used in the stone and granite industry refers to quality classification, not safety concerns.

Let’s take Sesame Grey (G654) marble, a widely used stone in architectural decoration and machine bases, as an example. In the stone industry, this material is often divided into three main grades—A, B, and C—based on color consistency, surface texture, and visible imperfections. The difference among these grades lies primarily in appearance, while the physical properties such as density, hardness, and compressive strength remain essentially the same.

A-grade marble represents the highest quality level. It features a uniform color tone, smooth texture, and a flawless surface without visible color variation, black spots, or veins. The finish appears clean and elegant, making it ideal for high-end architectural cladding, precision marble platforms, and indoor decorative surfaces where visual perfection is important.

B-grade marble maintains similar mechanical performance but may display minor, naturally occurring variations in color or texture. There are usually no large black dots or strong vein patterns. This type of stone is widely used in projects that require a balance between cost and aesthetic quality, such as flooring for public buildings, laboratories, or industrial facilities.

C-grade marble, while still structurally sound, shows more visible color differences, dark spots, or stone veins. These aesthetic imperfections make it less suitable for fine interiors but perfectly acceptable for outdoor installations, walkways, and large-scale engineering projects. Even so, C-grade marble must still meet the essential requirements of integrity—no cracks or breaks—and maintains the same durability as higher grades.

In short, the classification of A, B, and C materials reflects visual quality, not safety or performance. Whether it is used for marble surface plates, precision granite platforms, or decorative architecture, all grades undergo strict selection and processing to ensure structural soundness and long-term stability.

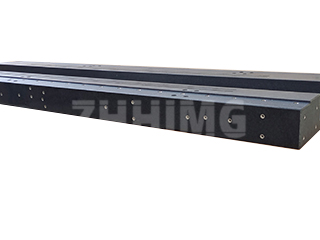

At ZHHIMG®, we prioritize material selection as the foundation of precision. Our ZHHIMG® black granite is engineered to outperform conventional marble in density, stability, and vibration resistance, ensuring that every precision platform we produce meets the highest international standards. Understanding the grading of materials helps customers make informed decisions—choosing the right balance between aesthetic requirements and functional performance.

Post time: Nov-04-2025