In the rigorous world of high-precision manufacturing and metrology, achieving perfect horizontal alignment is non-negotiable. Traditional bubble levels often fall short when sub-arcsecond accuracy is required. This is where the Electronic Level, an advanced measuring instrument, becomes an essential tool. It offers an unparalleled ability to measure minute angles and tilt with exceptional fidelity, playing a critical role in verifying the geometric accuracy of the most sophisticated machinery and tooling.

The Ingenious Physics Behind Electronic Levels

Electronic levels operate primarily through two highly sensitive physical principles: the inductance principle and the capacitance principle. Depending on their design, these instruments can measure tilt in one dimension (1D) or two dimensions (2D).

The Inductive Electronic Level relies on a change in magnetic flux. When the instrument’s base tilts due to the inclination of the workpiece being measured, an internal pendulum or sensitive mass shifts its position. This movement induces a corresponding voltage change in a nearby induction coil. The magnitude of this voltage change is directly translated into an angle of tilt.

Conversely, the Capacitive Electronic Level utilizes changes in electrical capacitance. At its core is a circular pendulum suspended freely by a fine wire, effectively operating in a frictionless state under the influence of gravity. Electrodes are positioned on either side of this pendulum. When the level is perfectly horizontal, the air gap on both sides is equal, resulting in identical capacitance values. When the level tilts, influenced by the workpiece, the pendulum shifts, causing the gap distances to become unequal. This alteration in distance results in a measurable difference in capacitance, which is then precisely converted into an angular measurement.

Applications in High-Accuracy Tooling

The electronic level is indispensable for verifying the flatness and alignment of high-precision machine tools and measuring equipment. Given its extreme sensitivity, the instrument can detect minute deviations critical to overall system performance. It is routinely deployed to measure the base surfaces of advanced machinery such as NC lathes, milling machines, cutting centers, and Coordinate Measuring Machines (CMMs). Its high resolution means that, even with a limited measuring range—often calculated to allow movement of ± 25 scale divisions—the device can provide accurate measurements within a tight and specific range of inclination, assuring the integrity of the machine setup.

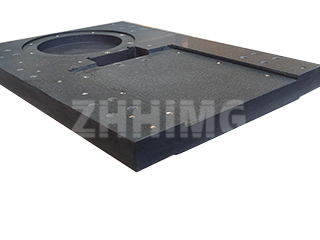

The Role in Flatness Verification: The Scraped Surface Plate

One particularly powerful application of the electronic level is the inspection of high-precision reference surfaces, such as scraped granite or cast iron surface plates. The electronic level provides a simple, yet profoundly accurate, method for assessing surface flatness.

When using the electronic level to examine these baseplates, the key procedural focus is determining the appropriate span length for the associated bridge (or measuring fixture), which is dependent on the overall size of the plate being tested. Critically, during the entire testing process, the movement of this bridge must be strictly interconnected and overlapping. This meticulous, step-by-step surveying method—where each subsequent measurement point links back to the previous one—is the primary factor that ensures the final calculated flatness value is as close to the true surface topography as possible.

Conclusion

The evolution from traditional bubble levels to sophisticated electronic levels represents a significant leap forward in quality control and metrology. By harnessing fundamental physics—be it induction or capacitance—these tools provide the data necessary to ensure that the foundational alignment of precision equipment meets the most exacting standards. For any facility dedicated to accuracy and product quality, understanding and implementing the electronic level is not just a best practice; it is a fundamental requirement for maintaining the competitive edge.

Post time: Nov-21-2025