Advantages of Granite Platforms

Granite Platform Stability: The rock slab is non-ductile, so there will be no bulges around pits.

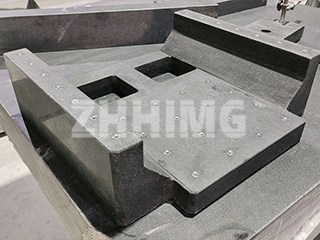

Characteristics of Granite Platforms: Black gloss, precise structure, uniform texture, and excellent stability. They are strong and hard, and offer advantages such as rust resistance, acid and alkali resistance, non-magnetization, deformation resistance, and excellent wear resistance. They can remain stable under heavy loads and at normal temperatures.

Development Trends of Granite Platforms and Components

Precision machining and micromachining technologies are important development directions in the machinery manufacturing industry. They have become an important indicator of a country’s high-tech level. The development of various technologies and the defense industry is inseparable from precision machining and micromachining technologies. Contemporary precision engineering, microengineering, and nanotechnology are the pillars of modern manufacturing technology. Furthermore, many new electromechanical products (including micro-electromechanical products) require increased precision and reduced dimensions to promote technological advancements across the machinery manufacturing industry, significantly improving the quality, performance, and reliability of mechanical products.

Appearance and Surface Quality Requirements and Verification Methods for Granite Slabs: Newly manufactured slabs should be marked with the manufacturer’s name (or factory logo), accuracy level, specifications, and serial number. The working surface of the rock slab should be uniform in color and free of cracks, depressions, or loose texture. It should also be free of wear marks, scratches, burns, or other defects that could affect the accuracy of the slab. The above defects are permitted in the slab during use as long as they do not affect accuracy. Repairs to depressions or chipped corners on the working surface of the rock slab are not permitted. Verification is by visual inspection and testing.

Precision machining and micromachining technologies are comprehensive techniques that integrate multiple disciplines, including mechanics, electronics, optics, computer control, and new materials. Natural granite is gaining increasing attention among these materials due to its unique properties. Using natural granite and other stone materials as components for precision machinery is a new development in the development of precision measuring instruments and precision machinery. Many industrialized countries around the world, such as the United States, Germany, Japan, Switzerland, Italy, France, and Russia, widely use granite as measuring tools and components for precision machinery.

Post time: Sep-02-2025