In the realm of precision manufacturing, granite components stand as the unsung heroes that underpin the accuracy of advanced machinery. From semiconductor production lines to cutting-edge metrology labs, these specialized stone structures provide the stable foundation necessary for nanoscale measurements and high-precision operations. At ZHHIMG, we’ve spent decades perfecting the art and science of granite component design, blending traditional craftsmanship with modern engineering principles to create solutions that meet the most demanding industrial standards.

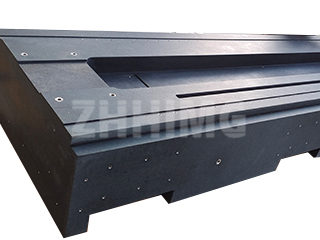

The journey of creating high-performance precision granite components begins with material selection—a critical decision that directly impacts the final product’s performance. Our engineers exclusively use ZHHIMG® black granite, a proprietary material with a density of approximately 3100 kg/m³ that outperforms many European and American granite varieties in both stability and physical properties. This dense structure not only provides exceptional vibration dampening but also ensures minimal thermal expansion, a key characteristic for maintaining precision in varying environmental conditions. Unlike some manufacturers who cut corners using marble substitutes, we remain committed to this superior material that forms the backbone of our components’ reliability.

Material selection alone, however, is just the starting point. The true complexity of granite component design reveals itself in the meticulous balancing of functional requirements with environmental realities. Every design must account for the interaction between the component and its operating environment, including temperature fluctuations, humidity levels, and potential vibration sources. Our 10,000 m² Temperature and humidity control workshop (constant temperature and humidity workshop) is specifically engineered to address these challenges, featuring 1000 mm thick ultra-hard concrete floors and 500 mm wide, 2000 mm deep anti-vibration trenches that create an optimal environment for both manufacturing and testing.

Mechanical precision is another cornerstone of effective granite component design. The integration of metal inserts into granite requires exacting tolerances to ensure proper load distribution and torque transmission. Our design team carefully considers whether traditional fasteners might be replaced with more precise groove-based systems, always evaluating the trade-offs between structural integrity and manufacturing feasibility. Surface characteristics同样 demand rigorous attention—flatness must often be maintained to within micrometer levels, while air bearing surfaces require specialized finishing techniques to achieve the necessary smoothness for frictionless motion.

Perhaps most importantly, modern granite component design must anticipate the specific demands of its intended application. A base for a semiconductor inspection machine, for example, faces vastly different requirements than a surface plate for a metrology lab. Our engineers collaborate closely with clients to understand not just the immediate dimensional needs but also the long-term performance expectations. This collaborative approach has led to components that serve critical roles in applications ranging from laser micromachining systems to advanced coordinate measuring machines (CMMs).

The manufacturing process itself represents the convergence of traditional craftsmanship and cutting-edge technology. Our facility houses four Taiwan Nante grinding machines, each exceeding $500,000, capable of processing workpieces up to 6000 mm in length with sub-micron precision. Yet alongside this advanced equipment, you’ll find master craftsmen with over three decades of experience who can achieve nanoscale accuracy through hand lapping—a skill we often refer to as “artisan metrology.” This combination of old and new allows us to tackle the most complex component geometries while maintaining the highest standards of precision.

Quality assurance permeates every stage of our design and manufacturing process. We’ve invested heavily in creating a comprehensive measurement ecosystem that includes German Mahr Dial gauge (dial indicators) with 0.5 μm resolution, Mitutoyo coordinate measuring systems, and Renishaw laser interferometers. Each of these instruments undergoes regular calibration by the Jinan and Shandong Metrology Institutes, ensuring traceability to national standards. This commitment to measurement excellence aligns with our corporate philosophy: “If you can’t measure it, you can’t produce it.”

Our dedication to precision and quality has earned us partnerships with industry leaders worldwide, including GE, Samsung, and Bosch, as well as prestigious research institutions like Singapore National University and Stockholm University. These collaborations continually push us to refine our design methodologies and explore new frontiers in ZHHIMG granite technology. Whether we’re developing a custom air bearing stage for a European semiconductor manufacturer or a precision surface plate for an American metrology lab, the core principles of material science, mechanical engineering, and environmental control remain our guiding forces.

As manufacturing continues its relentless march toward ever-greater precision, the role of precision granite components will only grow in importance. These remarkable structures bridge the gap between the mechanical and digital worlds, providing the stable platform upon which our most advanced technologies rely. At ZHHIMG, we’re proud to carry forward the legacy of precision granite craftsmanship while embracing the innovations that will define the future of manufacturing. Our ISO 9001, ISO 45001, ISO 14001, and CE certifications stand as testament to our commitment to quality, safety, and environmental responsibility—values that are embedded in every component we design and produce.

In the end, successful granite component design is about more than just meeting specifications; it’s about understanding the deeper purpose behind each measurement, each tolerance, and each surface finish. It’s about creating solutions that enable our clients to push the boundaries of what’s possible in precision manufacturing. As we look to the future, we remain dedicated to advancing the science of granite component design, ensuring that these critical elements continue to support the technological innovations that shape our world.

Post time: Nov-03-2025