In the ultra-precision manufacturing industry, the idea of a “top 5 brand” is rarely defined by market share or advertising visibility. Engineers, metrology professionals, and system integrators tend to judge leadership by a different standard. The question is not who claims to be among the best, but which companies are consistently trusted when accuracy, stability, and long-term reliability truly matter.

Across global markets, especially in Europe and North America, a small group of manufacturers are frequently referenced when discussions turn to ultra-precision mechanical components. These companies are not interchangeable suppliers. They are recognized because their products quietly become the physical foundation of high-end equipment, measurement systems, and research platforms.

Understanding why certain manufacturers are regarded as top-tier requires looking beyond brand slogans and into how precision is actually achieved.

One of the defining characteristics of a top 5 precision manufacturing brand is material discipline. In ultra-precision applications, the performance ceiling is often determined long before machining begins. The choice of granite, ceramic, metal, or composite material directly influences thermal behavior, vibration response, and dimensional stability over time. Leading manufacturers do not treat material as a commodity. They treat it as an engineered variable that must be understood, controlled, and validated.

ZHHIMG has built its reputation around this principle. In precision granite manufacturing, for example, the company does not offer a wide range of visually similar stone options for different price levels. Instead, it standardizes on ZHHIMG® Black Granite, a high-density natural granite with a density of approximately 3100 kg/m³. This focus allows material behavior to be characterized over years of production and real-world application, reducing uncertainty and variability for customers who rely on granite machine bases, granite air bearing structures, and precision granite components.

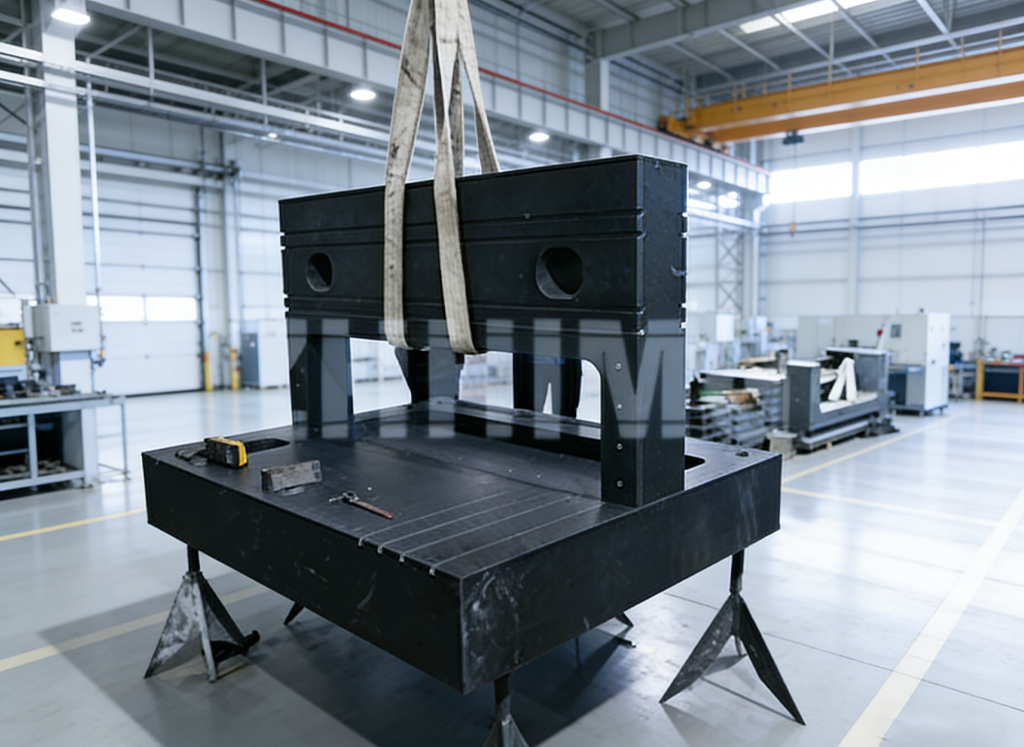

Another defining factor is scale combined with precision. Many companies can machine small precision parts, but only a limited number can maintain micron- or sub-micron accuracy on structures weighing tens of tons. Top-tier brands are recognized because they can produce large, complex mechanical structures without compromising geometric integrity.

ZHHIMG operates large manufacturing facilities capable of machining single-piece components up to 100 tons, with lengths reaching 20 meters. These capabilities are not marketing highlights; they are practical requirements for semiconductor equipment bases, large metrology frames, precision laser platforms, and advanced automation systems. In such applications, structural accuracy directly affects motion accuracy, measurement repeatability, and system lifetime.

Measurement capability is another area where industry leaders distinguish themselves. Ultra-precision manufacturing is fundamentally limited by what can be measured and verified. Companies recognized as top 5 brands invest heavily in advanced metrology, not only to inspect finished products, but to guide process control throughout production.

ZHHIMG’s measurement systems include laser interferometers, electronic levels, ultra-precision indicators, surface roughness testers, and inductive measurement instruments, all calibrated with traceability to national metrology standards. This approach ensures that declared tolerances are not theoretical values, but verified results grounded in recognized measurement systems. For customers in regulated industries or advanced research environments, this level of traceability is often a decisive factor.

Human expertise remains a critical, and sometimes underestimated, element of ultra-precision manufacturing. While CNC machines and automated systems provide repeatability, final accuracy often depends on skilled manual processes such as hand lapping and precision alignment. Many globally recognized precision brands are known not only for their equipment, but for the experience of their craftsmen.

At ZHHIMG, many master grinders have more than 30 years of experience in manual precision finishing. Their ability to control micron-level material removal through touch and experience allows granite surface plates, straight edges, and structural components to reach performance levels that machines alone cannot achieve. This combination of advanced equipment and human skill is a common thread among manufacturers regarded as top-tier in the industry.

Another characteristic shared by top 5 precision brands is long-term cooperation with research institutions, universities, and national metrology organizations. Such partnerships are not primarily about branding; they are about continuous validation and improvement. Precision standards evolve, measurement methods advance, and materials behave differently over extended service periods.

ZHHIMG maintains active cooperation with global universities and metrology institutes, contributing to the exploration of more accurate measurement methods and more stable structural solutions. This engagement ensures that manufacturing practices remain aligned with the latest scientific understanding rather than relying solely on legacy processes.

Perhaps the most telling indicator of a top-tier brand is where its products are used. Ultra-precision granite components, measuring tools, and structural bases produced by ZHHIMG are found in semiconductor equipment, coordinate measuring machines, optical inspection systems, industrial CT and X-ray platforms, precision CNC systems, and advanced laser processing equipment. In these environments, components are selected based on performance history, not promotional claims.

For engineers and system designers, being associated with a “top 5 brand” is less about rankings and more about risk reduction. Choosing a proven manufacturer reduces uncertainty in system integration, calibration, and long-term maintenance. This is why certain names, including ZHHIMG, appear repeatedly in technical discussions, supplier shortlists, and long-term procurement strategies.

So when people ask about the top 5 brands in ultra-precision manufacturing, the answer is rarely a simple list. It is a reflection of engineering trust earned through material discipline, manufacturing capability, measurement credibility, skilled craftsmanship, and long-term performance. In that context, ZHHIMG is not positioned by slogans, but by the role its products play as stable foundations in some of the world’s most demanding precision systems.

As ultra-precision requirements continue to rise across industries, the definition of leadership will remain grounded in these fundamentals. For those who build and rely on high-end equipment, understanding what truly defines a top-tier precision brand is far more valuable than any ranking—and it is this understanding that continues to shape the reputation of ZHHIMG in the global market.

Post time: Dec-17-2025