At the heart of the ultra-precision industry—from semiconductor manufacturing to aerospace metrology—lies the granite platform. Often overlooked as just a solid block of stone, this component is, in reality, the most crucial and stable foundation for achieving accurate measurements and motion control. For engineers, metrologists, and machine builders, understanding what truly defines the “precision” of a granite platform is paramount. It’s not simply about surface finish; it’s about a collection of geometric indicators that dictate the platform’s real-world performance.

The most important indicators of a granite platform’s precision are Flatness, Straightness, and Parallelism, all of which must be verified against rigorous international standards.

Flatness: The Master Reference Plane

Flatness is arguably the single most critical indicator for any precision granite platform, especially a Granite Surface Plate. It defines how closely the entire working surface conforms to a theoretical perfect plane. In essence, it is the master reference from which all other measurements are taken.

Manufacturers like ZHHIMG ensure flatness by conforming to globally recognized standards such as DIN 876 (Germany), ASME B89.3.7 (USA), and JIS B 7514 (Japan). These standards define tolerance grades, typically ranging from Grade 00 (Laboratory Grade, demanding the highest precision, often in the sub-micron or nanometer range) to Grade 1 or 2 (Inspection or Toolroom Grade). Achieving laboratory-grade flatness requires not only the inherent stability of high-density granite but also the exceptional skill of master lappers—our craftsmen who can manually achieve these tolerances with a precision often referred to as “micrometer feel.”

Straightness: The Backbone of Linear Motion

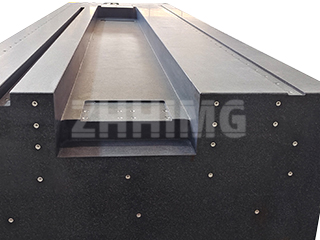

While flatness refers to a two-dimensional area, Straightness applies to a specific line, often along the edges, guides, or slots of a granite component like a straight edge, square, or machine base. In machine design, straightness is essential because it guarantees the true, linear path of motion axes.

When a granite base is used to mount linear guides or air bearings, the straightness of the mounting surfaces directly translates to the linear error of the moving stage, impacting positioning accuracy and repeatability. Advanced measurement techniques, particularly those utilizing laser interferometers (a core part of ZHHIMG’s inspection protocol), are required to certify straightness deviations in the realm of micrometers per meter, ensuring the platform acts as a flawless backbone for dynamic motion systems.

Parallelism and Perpendicularity: Defining Geometric Harmony

For complex granite components, such as machine bases, air bearing guides, or multi-faceted parts like granite squares, two additional indicators are vital: Parallelism and Perpendicularity (Squareness).

- Parallelism dictates that two or more surfaces—such as the top and bottom mounting surfaces of a granite beam—are exactly equidistant from each other. This is crucial for maintaining a constant working height or ensuring that components on opposite sides of a machine are perfectly aligned.

- Perpendicularity, or squareness, ensures that two surfaces are precisely 90° to each other. In a typical Coordinate Measuring Machine (CMM), the granite square ruler, or the component base itself, must have guaranteed perpendicularity to eliminate Abbe error and guarantee that the X, Y, and Z axes are truly orthogonal.

The ZHHIMG Difference: Beyond Specification

At ZHHIMG, we believe that precision cannot be over-specified—The precision business can’t be too demanding. Our commitment goes beyond meeting these dimensional standards. By utilizing high-density ZHHIMG® Black Granite (≈ 3100 kg/m³), our platforms inherently possess superior vibration damping and the lowest thermal expansion coefficient, further protecting the certified flatness, straightness, and parallelism from environmental and operational disturbances.

When evaluating a precision granite platform, look not only at the specification sheet but at the manufacturing environment, the certifications, and the traceable quality control—the very elements that make a ZHHIMG® component the most stable and reliable choice for the world’s most demanding ultra-precision applications.

Post time: Oct-24-2025