When engineers and system integrators search for the best granite manufacturers, they are rarely looking for a simple list of company names. In ultra-precision engineering, the word “best” carries a very specific meaning. It is not about production volume alone, nor about how widely a brand is promoted. Instead, it reflects long-term stability, measurable accuracy, and the ability to serve as a physical reference in systems where errors cannot be hidden.

Granite has been used in precision engineering for decades, yet only a small number of manufacturers are consistently trusted in high-end applications. This is because precision granite is not a decorative material. It is a functional foundation. Once installed as a machine base, measuring reference, or structural platform, its performance directly influences the accuracy, repeatability, and lifetime of the entire system.

The best granite manufacturers are therefore defined not by how many products they sell, but by how reliably their granite performs under real operating conditions.

One of the most important factors separating high-level granite manufacturers from ordinary suppliers is material control. Granite is a natural material, and its performance depends heavily on mineral composition, grain structure, density, and internal stress. Stones with similar appearance can behave very differently over time. In ultra-precision applications, these differences are amplified rather than averaged out.

ZHHIMG has built its precision granite manufacturing philosophy around strict material discipline. Instead of offering multiple visually similar granite grades, the company standardizes on ZHHIMG® Black Granite, a high-density natural granite with a density of approximately 3100 kg/m³. This material has been selected through long-term testing, processing experience, and application feedback in demanding industrial environments.

Compared with commonly used black granites in Europe and North America, ZHHIMG® Black Granite demonstrates higher density and improved structural stability. These characteristics are especially important for large granite machine bases, granite air bearing structures, and ultra-precision granite components, where even micro-level deformation can affect motion accuracy and measurement credibility.

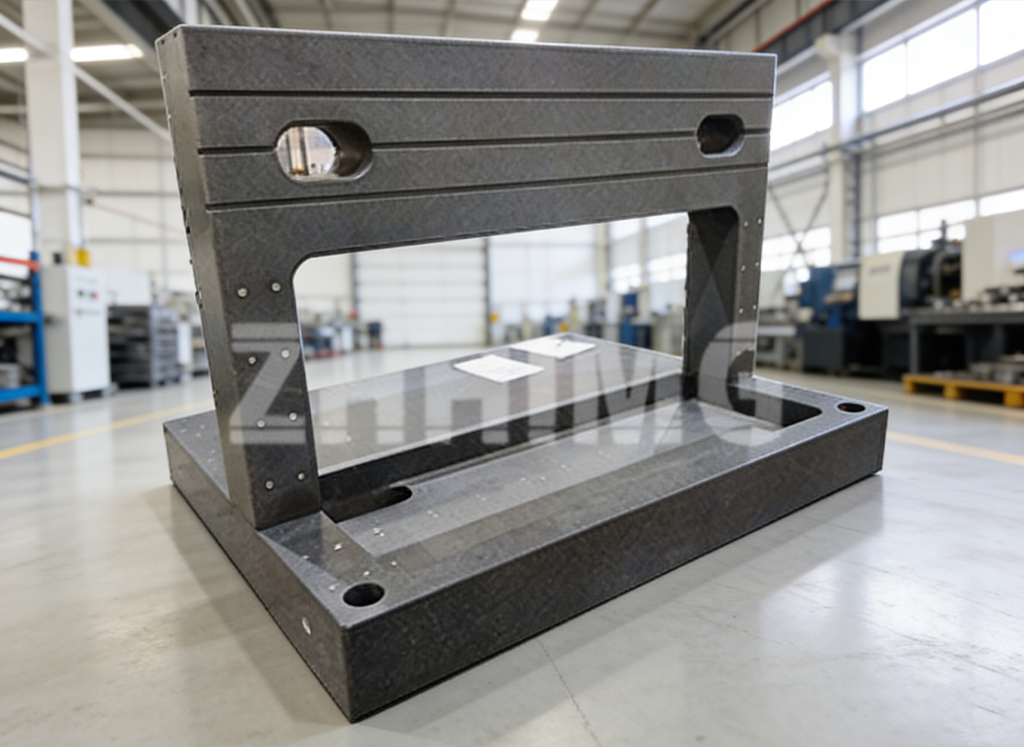

Another defining trait of the best granite manufacturers is their ability to combine scale with precision. Producing small granite plates with reasonable flatness is one thing. Maintaining micron- or sub-micron accuracy on components weighing tens of tons is another challenge entirely. In large semiconductor equipment bases, coordinate measuring machine structures, and precision laser platforms, geometric integrity must be preserved across long spans and heavy loads.

ZHHIMG operates large manufacturing facilities capable of machining single-piece granite components up to 100 tons, with lengths reaching 20 meters. These capabilities allow the company to support applications where structural size and precision must coexist. More importantly, they ensure that customers do not need to compromise design requirements due to manufacturing limitations.

Precision granite manufacturing also depends heavily on environmental control. Temperature fluctuation, vibration, and humidity variation can introduce measurement error during grinding and inspection. Manufacturers regarded as best-in-class invest not only in machines, but in the environment surrounding those machines.

ZHHIMG’s precision grinding and inspection processes are carried out in constant temperature and humidity workshops with vibration-isolated foundations. Silent overhead cranes and controlled assembly areas further reduce environmental disturbance. This attention to detail ensures that measured accuracy reflects true component performance rather than temporary conditions.

Measurement capability is another area where leading granite manufacturers distinguish themselves. Precision cannot exceed the accuracy of the measurement system used to verify it. The best manufacturers treat metrology as an integral part of production rather than a final inspection step.

ZHHIMG employs advanced metrology equipment including laser interferometers, electronic levels, ultra-precision indicators, surface roughness testers, and inductive measurement systems. All instruments are regularly calibrated with traceability to national metrology standards. This ensures that flatness, straightness, squareness, and parallelism values are not theoretical targets, but verified results.

Human expertise remains equally important. While modern CNC and grinding equipment provide consistency, final accuracy often depends on manual processes such as hand lapping and precision adjustment. Many of the world’s most respected granite manufacturers are known for the experience of their craftsmen rather than the novelty of their machines.

At ZHHIMG, many master grinders have more than 30 years of experience in manual precision finishing. Their ability to control micron-level material removal through touch and experience allows granite surface plates, straight edges, and structural components to achieve performance levels that automated processes alone cannot guarantee. This combination of technology and craftsmanship is a hallmark of manufacturers trusted in high-end applications.

The application range of precision granite products also reveals much about a manufacturer’s standing. Granite components produced by ZHHIMG are widely used in semiconductor equipment, PCB drilling machines, coordinate measuring machines, optical inspection systems, industrial CT and X-ray platforms, precision CNC equipment, femtosecond and picosecond laser systems, linear motor stages, and advanced energy equipment. In these systems, granite is not an optional upgrade; it is a critical functional element.

Granite measuring tools further illustrate this role. Precision granite surface plates serve as reference standards in metrology laboratories and inspection rooms. Granite straight edges, square rulers, V-blocks, and parallels are used for equipment assembly, alignment, and calibration. When these tools are inaccurate, every measurement based on them becomes questionable. By using consistent high-density granite material and controlled manufacturing processes, ZHHIMG ensures that its measuring tools provide reliable and repeatable reference surfaces.

Beyond production, the best granite manufacturers maintain close relationships with universities, research institutions, and national metrology organizations. These collaborations support continuous improvement in material understanding, measurement methods, and long-term performance evaluation. ZHHIMG actively cooperates with global academic and metrology institutions, ensuring that its manufacturing practices remain aligned with evolving precision standards.

Ultimately, searching for the best granite manufacturers is not about finding a name on a list. It is about identifying companies whose products quietly support the most demanding precision systems in the world. It is about consistency, traceability, and trust earned through performance rather than promotion.

In this context, ZHHIMG is recognized not because it claims leadership, but because its precision granite components, measuring tools, and structural bases are repeatedly selected for applications where failure is not an option. As ultra-precision requirements continue to increase across industries, the qualities that define the best granite manufacturers will remain unchanged. Material discipline, manufacturing capability, measurement credibility, and skilled craftsmanship will continue to matter more than rankings.

For engineers and decision-makers seeking reliable precision granite solutions, understanding these fundamentals is the first step toward choosing a partner that can support accuracy not only today, but over the entire lifetime of the equipment.

Post time: Dec-17-2025