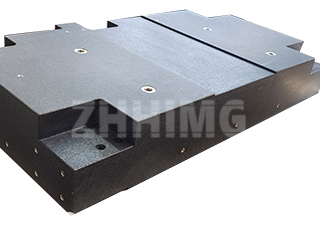

The Role of the Granite Core

A granite crossbeam is far more than a simple structural element; it is a precision reference tool—the certified backbone of any advanced metrology or machining system. In assemblies ranging from gantry cutters to complex coordinate measuring machines (CMMs) , the granite serves as the perfectly flat, non-deforming workbench required for scribing, measuring, and integrating complex mechanical movements.

The inherent stability of granite—its resistance to rust, acid, magnetism, and temperature variation—allows technicians to focus exclusively on the precision of the moving parts being mounted. When you build on a ZHHIMG® granite crossbeam, you are building on a perfect plane. However, even the perfect plane requires meticulous execution during component integration.

The Foundation of a Flawless Assembly

For the final machine to achieve and sustain its required accuracy, every component attached to the granite crossbeam must adhere to stringent quality and preparation standards. This is where mechanical assembly transitions from an art to a science:

1. Preparation: The Absolute Clean Slate

Before any mating occurs, every single component must be spotlessly clean. This isn’t just about appearance; it’s about eliminating micro-contaminants that destroy precision. All residual foundry sand, rust, and debris must be meticulously removed. For complex parts like inner cavities or gantry components, applying an inner coating of anti-rust paint after cleaning is a critical step. Diesel, kerosene, or gasoline are often used as cleaning fluids to dissolve oil and grease, followed by thorough drying with compressed air to prevent any residue from compromising fitment.

2. Dimensional Integrity and Fitment

The core principle of precision assembly is simple: dimensions must be accurate. During integration onto the granite crossbeam, technicians must recheck—or at minimum, conduct random checks—of all critical mating dimensions. This includes the precise center distance, the fit between main journals and bearings, and the tolerances of bearing mounting holes. Any deviation here will translate directly into runout, vibration, or reduced machine lifespan. Furthermore, joint surfaces must be flawlessly smooth and flat. Any burrs or deformations must be trimmed to ensure the components achieve full, tight contact against the granite’s reference surface without any skewing or gaps.

3. Lubrication and Sealing: Protecting the Movement

To ensure mechanical components move smoothly and resist wear, proper lubrication and sealing are non-negotiable. Mating surfaces, particularly within bearing assemblies in the spindle box or the nuts of a lifting mechanism, must be pre-lubricated before connection.

Seals, such as O-rings, must be handled with extreme care. They must be pressed parallel into their grooves, strictly without twisting or deformation, and the sealing surface must be free of damage or scratches. A compromised seal invites contamination, which is the nemesis of precision.

4. The Precision of Rotational and Linear Motion

Assemblies involving power transmission, such as wheel, gear, or pulley systems, have additional geometric constraints.

For gear assembly, the axes of the two gears must be perfectly coplanar and parallel, ensuring the correct, uniform normal tooth backlash. Similarly, for pulley assembly, the axes must be parallel, and the groove centers must be perfectly aligned. Significant axial deviation or misalignment will cause uneven tension, leading to belt slippage, excessive vibration, and rapid wear—all of which undermine the stability provided by the granite base. Selecting a matched V-belt set before installation is essential to prevent vibration during power transmission.

5. Bearing Installation: The Point of Highest Precision

Bearing assembly demands the highest level of care. After removing the anti-rust paint and thoroughly cleaning the bearing, technicians must check the raceway and rolling elements for corrosion and ensure flexible rotation. During installation, the force must be applied evenly and symmetrically to the inner or outer ring, using the correct tools to prevent impact or tilting. The force must be appropriate—if excessive pressure is required, assembly must stop immediately for inspection, as this indicates a serious dimensional mismatch that could ruin the bearing and compromise the entire assembly.

By combining the unwavering structural integrity of a ZHHIMG® granite crossbeam with these rigorous assembly requirements, engineers ensure the resulting machine operates with the sustained, nanometer-level precision expected by the global ultra-precision industry.

Post time: Nov-12-2025