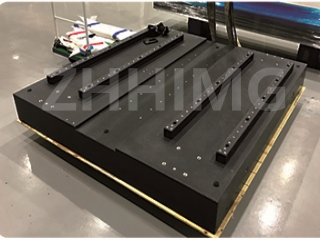

A granite surface plate is a precision tool crafted from high - density granite, renowned for its stability, durability, and flatness. Widely used in manufacturing, metrology, and quality control, it serves as a fundamental platform for ensuring accuracy in critical measurements and inspections. Below are its core applications and benefits:

1. Precision Measurement and Calibration

The primary role of a granite surface plate is to provide a flat, stable reference surface for measuring tools and components. Its inherent properties—such as low thermal expansion, resistance to corrosion, and minimal deformation over time—make it ideal for:

Calibrating instruments: Tools like micrometers, dial indicators, and coordinate measuring machines (CMMs) are tested and calibrated on the plate to ensure they deliver accurate readings.

Verifying part dimensions: Manufacturers place components directly on the plate to check flatness, squareness, or parallelism using gauges or laser interferometers. For example, in aerospace, turbine blades are inspected for minute deviations from design specifications.

Micrometer - level accuracy: High - grade plates (e.g., Grade A) can achieve flatness tolerances as tight as ±0.00008 inches, making them indispensable in industries like semiconductor fabrication, where precision is critical.

2. Quality Control and Inspection

In production lines, granite surface plates act as quality control hubs to ensure components meet strict standards:

Surface finish assessment: Machined parts (e.g., engine blocks, gears) are placed on the plate to check for surface roughness or imperfections using profilometers or optical comparators.

Assembly verification: During component assembly (e.g., in robotics or medical devices), the plate ensures parts are aligned correctly, reducing errors that could lead to product failure.

Compliance with standards: Industries adhering to ISO, ASME, or automotive standards (e.g., IATF 16949) rely on granite plates to validate measurements and maintain regulatory compliance.

3. Tool and Fixture Setup

Granite surface plates simplify the setup of machining tools and fixtures:

Jig and fixture alignment: Machinists use the plate to position drilling, milling, or grinding fixtures with precision, ensuring consistent part dimensions across batches.

Cutting tool calibration: Tools like end mills or lathe bits are adjusted on the plate to achieve the correct angles and heights before use, minimizing material waste and improving efficiency.

4. Laboratory and Research Applications

In scientific research and development (R&D), granite plates provide a stable platform for sensitive experiments:

Optical and laser setups: In physics labs, the plates support interferometers or spectrometers, where vibrations or temperature changes could skew results.

Material testing: Samples for hardness testing (e.g., Rockwell or Vickers tests) are placed on the plate to ensure uniform loading and accurate data collection.

5. Advantages Over Metal Plates

Granite’s unique properties give it a competitive edge over steel or cast iron plates:

Thermal stability: Granite absorbs heat slowly and has a low coefficient of thermal expansion, making it reliable in fluctuating temperatures (e.g., 车间 environments).

Non - magnetic and corrosion - resistant: It won’t interfere with magnetic tools or degrade when exposed to oils, coolants, or humidity.

Longevity: With proper care, a granite plate can last decades without losing its flatness, offering a high return on investment.

Conclusion

A granite surface plate is more than just a “flat slab”—it’s a cornerstone of precision manufacturing and quality assurance. Whether used to calibrate instruments, inspect critical components, or support complex experiments, its stability and accuracy make it irreplaceable in industries where even minor errors can have significant consequences. By investing in a high - quality granite plate, businesses can enhance productivity, reduce defects, and maintain the trust of clients who demand excellence.

Post time: May-23-2025