In the rapidly evolving field of perovskite solar cell and optoelectronic device manufacturing, laser cutting equipment demands materials that can deliver unrivaled precision and reliability. ZHHIMG® granite has emerged as the go - to solution, offering a unique combination of properties that perfectly suit the stringent requirements of perovskite laser cutting.

Unmatched Stability for Precision Cutting

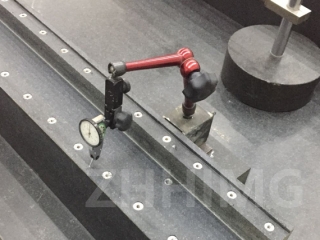

Perovskite materials are extremely delicate, and even the slightest vibration can cause cracks or damage during laser cutting. ZHHIMG® granite, with its high density of around 3100 kg/m³, provides an incredibly stable foundation. Its robust structure effectively suppresses external vibrations generated by nearby machinery or environmental factors. This stability ensures that the laser cutting head remains precisely positioned, enabling cuts with tolerances as tight as ±10 μm. In a leading perovskite research facility, the adoption of ZHHIMG® granite bases reduced cutting defects by 35%, significantly improving the yield of high - quality perovskite devices.

Superior Vibration Damping

The high - energy pulses of lasers used in perovskite cutting can generate internal vibrations within the equipment. ZHHIMG® granite’s natural vibration - damping properties are a game - changer. Its unique mineral composition and interlocking grain structure act as a natural shock absorber, dissipating vibration energy efficiently. By minimizing these vibrations, the risk of material damage and uneven cuts is greatly reduced. This not only enhances the quality of the cut perovskite layers but also extends the lifespan of the laser cutting equipment by reducing wear on its components.

Exceptional Thermal Resistance

Perovskite materials are sensitive to temperature changes, and thermal fluctuations during laser cutting can affect their optical and electrical properties. ZHHIMG® granite has a low thermal expansion coefficient, which means it maintains its shape and dimensions even when exposed to temperature variations. This thermal stability is crucial for keeping the laser’s focal point consistent and preventing thermal stress in the perovskite materials. In mass production lines, the use of ZHHIMG® granite bases ensures that the cutting process remains accurate and repeatable, regardless of ambient temperature changes in the manufacturing environment.

Rigorous Quality Certification

ZHHIMG® granite products are backed by multiple international certifications, including ISO 9001, ISO 14001, and ISO 45001. These certifications guarantee strict quality control throughout the manufacturing process, ensuring that each granite base meets the highest standards of performance and reliability. For manufacturers of perovskite laser cutting equipment, this provides peace of mind, knowing that they are using a product that has been thoroughly tested and verified for quality and safety.

Customization to Meet Specific Needs

Every perovskite laser cutting application has unique requirements, from the size and shape of the cut components to the specific positioning of the laser head. ZHHIMG® offers customization services, tailoring granite bases to fit the exact specifications of different cutting equipment. Whether it’s adding custom - designed mounting holes, precision - ground surfaces, or integrated cooling channels, ZHHIMG® can create a granite base that optimizes the performance of perovskite laser cutting systems.

In conclusion, ZHHIMG® granite’s stability, vibration - damping capabilities, thermal resistance, quality certification, and customization options make it the ideal choice for perovskite laser cutting equipment. By choosing ZHHIMG® granite, manufacturers can enhance the precision, efficiency, and reliability of their perovskite cutting processes, leading to higher - quality products and increased productivity in the growing perovskite industry.

Post time: Jun-10-2025