Precision granite platforms have become an essential foundation for ultra-precision manufacturing, high-end metrology, and semiconductor equipment assembly. Their superior stability, thermal resistance, and wear characteristics make them the preferred choice for industries that demand the highest levels of accuracy. However, selecting the right granite platform for environments with significant vibrations—such as next to heavy CNC machines or industrial production lines—requires careful consideration beyond standard flatness or dimensional tolerances.

Vibration is one of the most critical factors affecting measurement accuracy and operational stability. Even slight oscillations transmitted from nearby machinery can compromise the performance of sensitive equipment, leading to measurement errors, reduced machining precision, and accelerated wear of both the granite platform and the mounted instruments. Therefore, understanding how granite interacts with dynamic environments is crucial for engineers and quality managers who aim to maintain long-term precision.

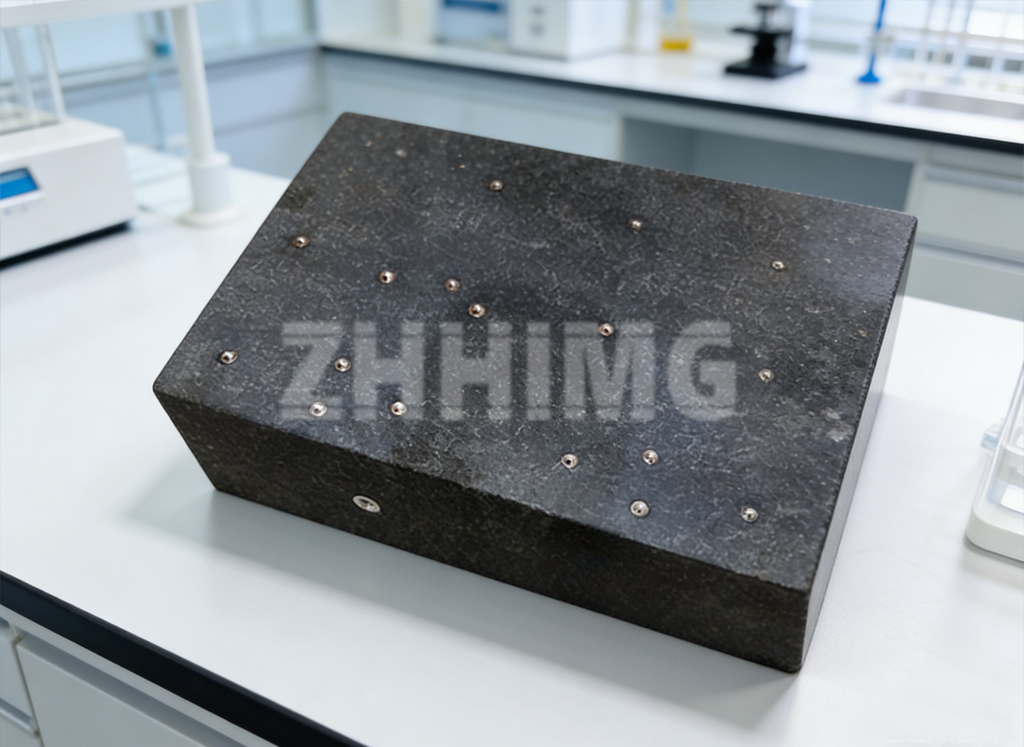

One key factor to consider is the inherent damping capacity of the granite material. Not all granite is created equal. High-density black granite, such as ZHHIMG® Black Granite, offers superior vibration absorption due to its fine-grained structure and uniform density. Its physical properties, including a density of approximately 3100 kg/m³ and excellent modulus of elasticity, make it far more resistant to vibration-induced deformation than lower-quality granite or marble alternatives. Choosing granite with insufficient density or inconsistent structure may result in amplified resonance under machine-induced vibrations, which can compromise precision measurements.

Equally important is the design and thickness of the platform. Platforms exposed to vibration should be engineered with increased mass and optimized support points to enhance natural damping. Thicker plates and integrated reinforcement can significantly reduce amplitude and frequency transmission from adjacent equipment. Furthermore, the placement of support points should be carefully aligned with both the platform’s natural frequency and the vibration profile of surrounding machinery. A misaligned support system can inadvertently amplify vibrations rather than absorb them, undermining the platform’s precision.

Surface flatness and geometry retain their critical roles even in high-vibration environments. A platform that initially meets strict flatness tolerances may still experience micro-deformations over time if it is subjected to continuous oscillatory loads. Therefore, selecting granite platforms with proven long-term dimensional stability, as well as materials with minimal thermal expansion, is essential. High-performance platforms are often paired with controlled-environment assembly and regular calibration routines to ensure that the surface remains stable despite vibration exposure.

Installation environment also plays a significant role. Platforms should ideally be isolated from direct contact with vibration sources. While industrial floors inherently transmit some vibrations, the addition of vibration-damping mounts, air tables, or anti-vibration pads can further protect both the platform and the sensitive equipment mounted on it. Maintaining a stable temperature and humidity environment complements vibration isolation, as thermal expansion or contraction can interact with mechanical vibrations to produce compounded measurement errors.

At ZHHIMG®, we emphasize a holistic approach to precision platform selection. Our granite components and air-bearing platforms are engineered specifically for industrial environments where vibrations are unavoidable. By combining high-density ZHHIMG® Black Granite with expert craftsmanship and advanced assembly in our temperature-controlled and vibration-optimized workshops, we ensure that every platform maintains nanometer-level flatness and stability. Our decades of experience in supplying Fortune 500 companies, semiconductor manufacturers, and top research institutes demonstrate that careful material selection, proper support design, and environmental management are as important as initial machining precision.

For professionals looking to optimize measurement or machining accuracy in vibration-prone settings, the choice of platform should not be taken lightly. Selecting high-quality granite, understanding vibration characteristics, and implementing appropriate isolation strategies are essential steps for achieving consistent, reliable results. In environments where precision is paramount, a high-density, carefully engineered granite platform can mean the difference between marginal performance and uncompromised excellence.

Ultimately, investing in a platform designed for vibration resilience is an investment in long-term accuracy, efficiency, and equipment protection. With the right selection, even challenging industrial environments can support the ultra-precision demands of modern manufacturing and research applications.

Post time: Dec-15-2025