In the world of high-precision industrial measurement, even the slightest deviation can lead to significant errors. At ZHHIMG, we understand that reliable measurement tools are not just instruments—they are the foundation of quality, accuracy, and efficiency in manufacturing processes. Among the tools that have proven indispensable are the granite base for dial gauge applications and granite square rulers, including models with six precision surfaces and DIN 00 certification.

Granite has long been recognized as the material of choice for precision measurement. Its natural density, low thermal expansion, and exceptional wear resistance make it uniquely suited for environments where stability and accuracy are critical. A granite base for dial gauge ensures that the readings of sensitive measuring devices remain consistent, even under rigorous operational conditions. By providing a vibration-free and temperature-stable surface, these bases enable engineers and technicians to perform fine measurements with confidence, reducing errors and increasing production reliability.

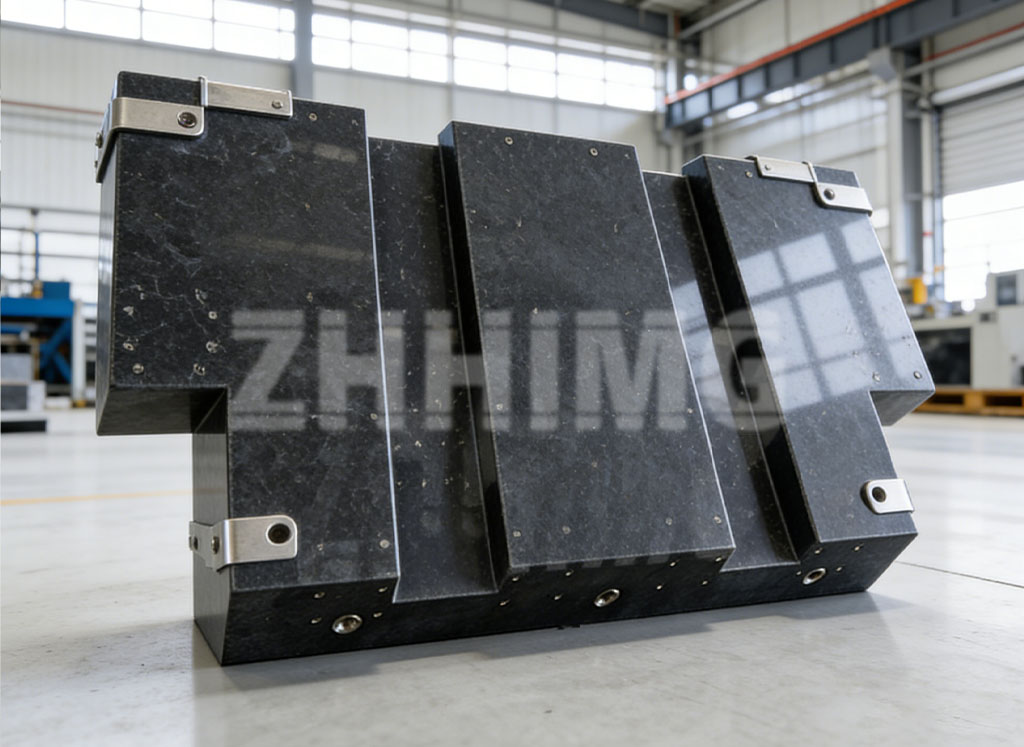

Equally important are granite square rulers, designed to deliver precise right-angle references and dimensional checks. The ZHHIMG granite square ruler with six precision surfaces offers versatility in measurement, allowing multiple points of contact without sacrificing accuracy. This multi-surface design is particularly valuable for complex assemblies or calibration tasks where alignment consistency is crucial. Meanwhile, our granite square ruler with DIN 00 certification meets the stringent European metrology standards, ensuring that professionals can rely on it for tasks that demand absolute precision.

Beyond material properties and certifications, the craftsmanship behind these tools plays a critical role. At ZHHIMG, every granite base and square ruler undergoes meticulous processing using advanced CNC equipment, followed by thorough inspection and calibration. This attention to detail ensures surface flatness at the micron level and edge straightness that exceeds industry standards. Such precision is essential in sectors ranging from semiconductor manufacturing and CNC machining to laboratory calibration and aerospace applications.

Maintenance and longevity are also central to the value of granite measurement tools. Unlike alternatives that may warp or degrade over time, granite surfaces remain stable for decades when properly cared for. Routine cleaning, avoiding heavy impacts, and controlling environmental factors such as humidity and temperature fluctuations are sufficient to preserve the accuracy of ZHHIMG granite bases and square rulers. This durability translates into long-term cost savings and consistent operational reliability for industrial facilities worldwide.

For professionals seeking dependable measurement solutions, the combination of material excellence, precise craftsmanship, and compliance with recognized standards makes ZHHIMG a trusted partner. Our granite bases for dial gauge and precision square rulers not only support critical measurement tasks but also enhance productivity, improve quality control, and instill confidence in engineering results.

As industries continue to evolve toward higher precision and tighter tolerances, the importance of reliable measurement instruments cannot be overstated. Granite measurement tools represent an investment in accuracy and stability, and with ZHHIMG’s expertise, clients gain tools that consistently deliver the performance required by the most demanding applications. Whether for calibration labs, advanced manufacturing, or precision assembly lines, our granite solutions provide a foundation that professionals can trust.

In choosing ZHHIMG granite bases and square rulers, customers worldwide benefit from products engineered with uncompromising precision, certified to international standards, and backed by decades of experience in ultra-precision manufacturing. The result is measurement confidence, operational efficiency, and the assurance that every micrometer counts.

Post time: Dec-30-2025