In recent years, the demand for stable, temperature-resistant, and vibration-damping machine foundations has grown rapidly across global precision industries. As semiconductor equipment, optical metrology systems, coordinate measuring machines, and advanced automation continue to push accuracy into the sub-micron range, the supporting structure beneath the machine becomes just as important as the machine itself. This is where the precision granite pedestal base has emerged as the preferred foundation material for engineers and equipment manufacturers who cannot tolerate dimensional drift or structural instability.

A black granite pedestal base is no longer seen as a passive block of stone. It has become an engineered component designed to deliver long-term dimensional stability, high rigidity, and excellent resistance to wear. Granite sourced for these bases must meet strict selection criteria, and at ZHHIMG, the material used is UNPARALLELED® Black Granite, known for its exceptional density, low porosity, and stable thermal response. This material provides a significant advantage over many European and American granites, particularly in environments where even minor temperature variations can affect measurement or machining accuracy.

The introduction of the Grade00 granite base standard has further shaped expectations for metrology and equipment stability. Grade00 is widely recognized as the highest accuracy level in the industry, offering an extremely tight flatness tolerance that ensures error-free performance when supporting precision assemblies. When a black granite precision base is engineered to Grade00 levels, it provides the foundation required for ultra-precision operations where repeatability and long-term reliability are non-negotiable.

More equipment manufacturers are turning to granite pedestal bases because alternative materials simply cannot match granite’s performance. Metal bases, for example, suffer from thermal expansion and internal stresses that evolve over time. Polymer concrete bases deliver good damping but lack the long-term wear resistance needed for high-duty industrial environments. Granite solves these problems through its natural stability and its ability to maintain structural accuracy for decades without deformation. Its resistance to corrosion and moisture further enhances its suitability for laboratories, cleanrooms, and high-vibration manufacturing floors.

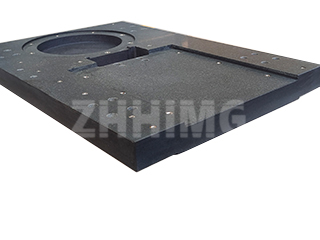

As machinery becomes more complex, pedestal bases are no longer simple monolithic structures. Modern precision granite pedestal base designs often integrate inserts, threaded bushings, T-slots, air-bearing interfaces, vibration isolation systems, cable routing channels, and custom machining features. These additions allow the granite base to serve as both a structural support and an integrated functional platform. ZHHIMG’s engineering team works closely with clients to customize each base so it fits perfectly with the machine architecture, ensuring both mechanical performance and ergonomic convenience.

Manufacturers in semiconductor lithography, optical inspection, advanced robotics, aerospace component testing, and micro-mechanical assembly increasingly adopt black granite pedestal bases because the material improves measurement reliability and production stability. The ability to maintain micro-level flatness and structural integrity under constant load makes granite indispensable in operations where a single micron of drift could compromise an entire manufacturing process. Its non-magnetic and low-conductivity characteristics also make it ideal for environments where electromagnetic interference or thermal distortion must be minimized.

Maintenance is straightforward and requires no special chemicals or coatings. A Grade00 granite base needs only regular cleaning with mild detergent and periodic inspection of mounting points and accessories. Because granite does not rust, warp, or age like metal, the maintenance cost over its lifetime is extremely low. If the working surface becomes worn over many years of use, it can be re-lapped by technicians to restore its original flatness—a significant advantage over metal structures that would require complete replacement.

The rapid development of precision engineering has made the foundation of each machine more critical than ever. A carefully engineered black granite precision base delivers performance that directly influences machine quality, measurement accuracy, and final product reliability. As industries adopt higher accuracy requirements, the precision granite pedestal base is becoming a strategic upgrade rather than an optional component. Its performance benefits translate directly into higher yield, better stability, and greater customer confidence.

ZHHIMG continues to support companies worldwide with customized granite bases engineered for long-term precision. Backed by ISO certifications, advanced manufacturing capabilities, and decades of experience in the ultra-precision field, the company provides solutions trusted by global leaders in semiconductor, metrology, automation, aerospace, and scientific research. As accuracy demands rise, granite will continue to play a central role in building the next generation of high-performance industrial systems.

Post time: Dec-02-2025