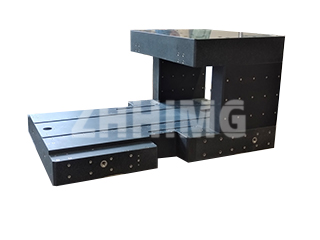

In the world of ultra-precision manufacturing and metrology, the granite machine base is far more than a simple slab of rock—it is the foundational element that dictates the performance ceiling of the entire system. At ZHONGHUI Group (ZHHIMG®), we understand that the external dimensions of these precision granite bases, used in everything from advanced semiconductor equipment to high-resolution optical instruments, are non-negotiable specifications. They are the key to stability, accuracy, and seamless integration.

This discussion delves into the stringent dimensional requirements that define a world-class granite base, ensuring its role as a perfect host for the most demanding mechanical and optical assemblies.

The Defining Factor: Extreme Dimensional Accuracy

The core demand for any granite component is dimensional accuracy, which extends far beyond basic length, width, and height. The tolerances for these fundamental dimensions must rigorously adhere to design specifications, ensuring perfect fit-up during the often complex assembly process. For the machinery that operates at the cutting edge of technology, these tolerances are significantly tighter than general engineering standards, demanding an extremely close fit between the granite base and the mating equipment interfaces.

Crucially, geometric accuracy—the relationship between the base’s surfaces—is paramount. The flatness and parallelism of the granite’s top and bottom surfaces are essential for zero-stress installation and maintaining equipment equilibrium. Furthermore, where vertical stages or multi-axis systems are involved, the verticality and coaxiality of mounting features must be verified through meticulous, high-resolution measurement. Failure in these geometries translates directly into compromised operational accuracy, which is simply unacceptable in precision engineering.

Consistency and Stability: A Foundation Built to Last

A reliable granite base must exhibit exceptional shape consistency and dimensional stability over time. While bases often feature straightforward rectangular or circular geometry to simplify installation, maintaining uniform dimensions across batches is critical for streamlined manufacturing and commissioning.

This stability is a hallmark of ZHHIMG® black granite, which benefits from its naturally low internal stress. Through precision grinding, lapping, and a meticulous manufacturing process conducted within our constant temperature and humidity environment, we minimize the potential for dimensional drift caused by minor thermal or humidity shifts. This long-term stability ensures that the base maintains its initial accuracy—and thus the equipment’s performance—throughout its operational life.

Seamless Integration: Adaptability and Compatibility

A granite base is not an isolated unit; it is an active interface within a complex system. Therefore, its dimensional design must prioritize equipment interface compatibility. Mounting holes, precision reference edges, and specialized positioning slots must align perfectly with the equipment’s installation requirements. At ZHHIMG®, this means engineering for specific standards, whether it involves integrating with linear motor platforms, air bearings, or specialized metrology tooling.

Furthermore, the base must be compatible with its working environmental compatibility. For applications in cleanrooms, vacuum chambers, or areas exposed to contaminants, the non-corrosive nature of granite, combined with appropriate dimensional features for sealing and mounting, ensures sustained stability and usability without degradation.

Designing the Optimal Base: Practical and Economic Considerations

The final dimensional design of a custom granite base is a balancing act of technical need, practical logistics, and cost-effectiveness.

Firstly, the equipment’s weight and dimensions are fundamental inputs. Heavy or large-format equipment necessitates a granite base with proportionally larger dimensions and thickness to achieve adequate stiffness and support. The base dimensions must also be considered within the constraints of the end-user’s facility space and operating access.

Secondly, transportation and installation convenience are practical constraints that influence design. While our manufacturing capabilities allow for monolithic components up to 100 tons, the final size must facilitate efficient handling, shipping, and on-site positioning. Thoughtful design includes consideration for lifting points and reliable fixing methods.

Finally, while precision is our primary mandate, cost-effectiveness remains a consideration. By optimizing the dimensional design and employing efficient, large-scale processing techniques—like those used in our facilities—we reduce manufacturing waste and complexity. This optimization provides a high-value product that meets the most demanding accuracy requirements while ensuring excellent return on investment for the equipment manufacturer.

In conclusion, the dimensional integrity of precision granite bases is a multi-faceted requirement essential for the stability and long-term performance of high-tech machinery. At ZHHIMG®, we combine world-class material science with advanced manufacturing precision to deliver bases that don’t just meet specifications, but redefine the possible.

Post time: Oct-30-2025