In the field of high-end manufacturing, the Fortune 500 companies have extremely strict requirements for the selection of suppliers. The choice of any component is related to product quality and the reputation of the enterprise. In recent years, many Fortune 500 suppliers have designated ZHHIMG granite components. One of the key factors behind this is that it has achieved an industry breakthrough with a thermal expansion coefficient of 0.01μm/°C.

For high-precision and sophisticated industries such as precision instrument manufacturing and semiconductor processing, temperature changes in the production environment are inevitable. Components made of traditional materials, due to their relatively high coefficient of thermal expansion, will undergo dimensional changes when the temperature fluctuates. Such minor changes are constantly magnified in precision operations, leading to a decline in equipment accuracy and an increase in the rate of defective products. According to relevant research, in some semiconductor chip manufacturing processes with extremely high precision requirements, for every 1°C change in temperature, the thermal expansion of ordinary metal components may cause the chip circuit deviation to exceed the allowable range, with a scrap rate as high as 20% to 30%, seriously affecting production efficiency and the economic benefits of enterprises.

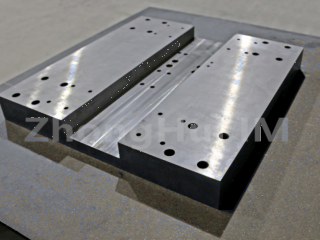

ZHHIMG granite components, with an ultra-low thermal expansion coefficient of 0.01μm/°C, have completely broken through this industry predicament. Natural granite undergoes a long geological process during its formation, resulting in a dense and uniform structure. Based on this, ZHHIMG has further optimized the performance of granite components by applying advanced processing techniques and quality control systems. When the external temperature changes, the dimensions of ZHHIMG granite components remain almost unchanged, providing consistent and stable support for the equipment. Take the precision optical inspection equipment as an example. After using the ZHHIMG granite components, even when working continuously in an environment with a large temperature difference between day and night, the measurement accuracy deviation of the equipment can be controlled within a very small range, ensuring the accuracy and reliability of the inspection results, and greatly improving the efficiency and accuracy of product quality inspection.

In addition to its outstanding thermal stability, ZHHIMG granite components also have many advantages. Its hardness is extremely high, reaching 6-7 on the Mohs scale. It can withstand high-intensity mechanical loads, is not prone to deformation or wear, and thus extends the service life of the equipment. Meanwhile, the natural shock absorption property of granite can effectively absorb the vibrations generated during the operation of equipment, reducing the impact of vibrations on processing accuracy. In semiconductor wafer cutting equipment, the application of ZHHIMG granite components makes the cutting process more stable, achieves higher cutting accuracy, significantly reduces the wafer breakage rate, and enhances production efficiency.

Fortune 500 companies attach great importance to long-term and stable cooperative relationships. ZHHIMG not only excels in product quality but also has a complete service system. ZHHIMG can provide customers with all-round support. Its professional technical team can respond quickly to customer demands, solve various problems encountered by customers during the usage process, and safeguard the production and operation of enterprises.

Post time: May-14-2025