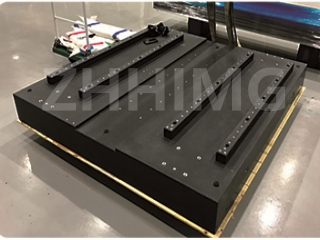

In the field of PCB precision drilling, ZHHIMG® granite base has become the preferred alternative to steel base due to its four core advantages:

1. Stable structure: Outstanding resistance to deformation

Black granite with a density of 3100kg/m³ is selected. The internal mineral crystals are dense and the natural internal stress is close to zero. Compared with the lattice slip problem of steel frames under long-term loads, granite frames can suppress over 90% of the deformation, ensuring that the drilling device maintains a positioning accuracy of ±1μm for a long time.

2. High vibration absorption efficiency: Drilling accuracy is improved by 3 times

The internal mineral friction of granite forms natural damping, which can absorb 90% of the vibration energy during the drilling process (steel bases can only absorb 30%). A certain PCB manufacturer's actual measurement shows that after installing a granite base, the roughness of the 0.1mm micro-hole wall dropped from Ra1.6μm to Ra0.5μm, and the service life of the drill bit was extended by two times.

Three. Strong thermal stability: The influence of temperature differences is minimized

The coefficient of thermal expansion is only 5.5×10⁻⁶/℃ (11.5×10⁻⁶/℃ for steel). When the continuous operating temperature of the equipment rises by 10℃, the thermal deformation of the granite base is less than 5μm, while that of the steel base can reach 12μm, effectively avoiding the hole position offset caused by thermal expansion and contraction.

Iv. Processing Accuracy: Guaranteed by nanometer-level standards

It is processed by a five-axis CNC grinding machine, with the flatness controlled within ±0.5μm/m, and supports custom T-slots, threaded holes and other complex structures. A case from a certain drilling equipment factory shows that the installation hole position accuracy of the granite machine base reaches ±0.01mm, which is 50% higher than that of the steel machine base, significantly reducing the equipment commissioning time.

Cost and environmental advantages: Although the initial cost is 15% higher, the service life exceeds 10 years (only 5 years for steel frames), and it requires no maintenance. The carbon emissions in the mining and processing of granite are 40% lower than those in steel smelting, which is in line with the trend of green manufacturing.

Post time: Jun-18-2025