At present, with the vigorous development of the photovoltaic industry, the world's TOP 3 photovoltaic enterprises have strict requirements for the precision and stability of production equipment. The selection of materials for the core component of the equipment, the base, is of vital importance. The ZHHIMG brand granite has stood out and become the first choice of these industry giants, and there are many deep-seated reasons behind this.

Outstanding physical properties

Ultra-high rigidity and stability

ZHHIMG brand granite has undergone a long period of natural aging treatment, resulting in a uniform internal structure and complete elimination of internal stress. It has excellent rigidity and can provide stable support for photovoltaic production equipment. During the operation of the equipment, in the face of various complex mechanical vibrations and external force impacts, the granite base, with its own high rigidity, effectively resists deformation, ensuring that the precision components inside the equipment always remain in a stable relative position, thereby guaranteeing the accuracy of the production process. Take silicon wafer cutting equipment as an example. During the high-speed cutting process, the ZHHIMG granite base can keep the positioning accuracy deviation of the cutting tool within a very small range, significantly reducing the cutting loss of silicon wafers and improving the product yield.

Extremely low coefficient of thermal expansion

The temperature in the photovoltaic production environment is not constant, and temperature fluctuations have a significant impact on the accuracy of the equipment. The coefficient of thermal expansion of ZHHIMG granite is extremely small, and the dimensional change is negligible when the temperature varies. Compared with traditional metallic materials, its coefficient of thermal expansion is only a fraction or even lower than that of metals. This feature enables the photovoltaic production equipment based on the ZHHIMG granite base to maintain stable processing accuracy even when the workshop temperature fluctuates in different seasons and production periods. For instance, in the printing process of solar cells, precise printing positions are the key to ensuring the photoelectric conversion efficiency of the solar cells. The stable thermal performance of the granite base avoids printing position deviations caused by temperature changes, thereby enhancing the production quality of the solar cells.

Outstanding damping performance

In the production workshop, the vibrations generated by the operation of equipment can interfere with each other, affecting the production accuracy. ZHHIMG brand granite has outstanding damping properties and can rapidly absorb and attenuate vibration energy. The complex mineral structure and tiny pores inside it act like natural vibration absorbers, converting vibrations into heat energy and dissipating it. When multiple photovoltaic devices are operating simultaneously, the granite base effectively blocks the transmission of vibrations between the devices, creating a relatively quiet and stable production environment. In the component lamination process, a stable working environment helps improve the lamination quality, reduce the occurrence of defects such as bubbles and delamination, and enhance the reliability of photovoltaic modules.

Strict quality control and customization capabilities

High-standard quality control system

ZHHIMG has established a complete and strict quality control system. From the mining and screening of granite raw materials, to every process in the processing, and then to the inspection of finished products, all follow international authoritative standards such as DIN, ASME, JJS, GB, etc. During the raw material selection stage, only high-quality and uniformly textured ores are used to ensure that each piece of granite used for production possesses excellent basic characteristics. During the processing, advanced CNC machining technology is employed in combination with an experienced technical team to ensure that the dimensional accuracy of the products can reach 0.001mm or even higher. In the finished product inspection stage, professional inspection equipment and technology are used to strictly test key indicators such as flatness, straightness and parallelism of the products. Only products that fully meet the standards will enter the market, providing reliable quality assurance for photovoltaic enterprises.

Customized solutions

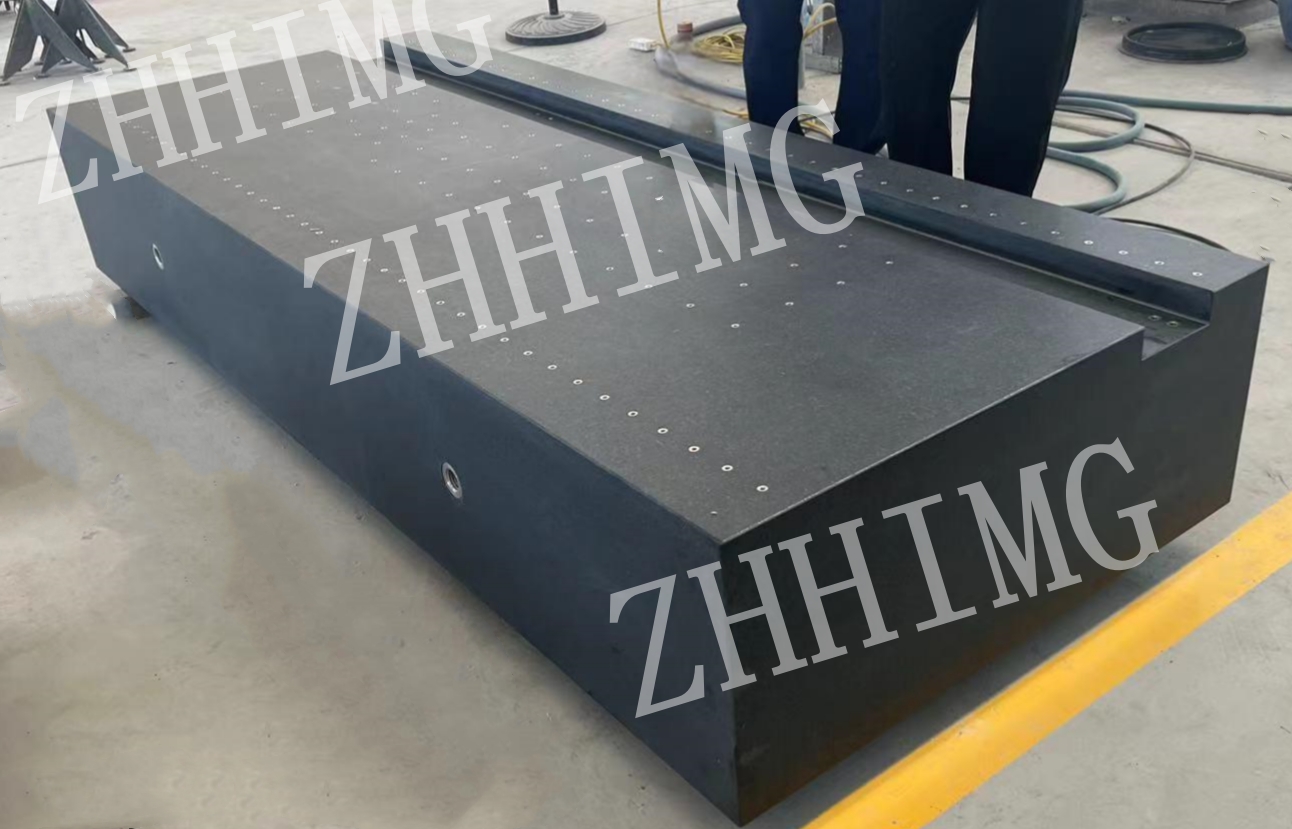

The production processes and equipment demands of the world's TOP 3 photovoltaic enterprises vary. ZHHIMG fully leverages its technological advantages to provide customized granite products. Whether it is a base of special size specifications or a complex installation structure that needs to be designed on granite components and precise positioning holes reserved, ZHHIMG can produce according to the specific drawings and requirements of enterprises. For instance, to meet the special layout of a new high-efficiency battery production line of a certain photovoltaic enterprise, ZHHIMG customized a granite platform with a unique support structure and interface design, which perfectly fits the installation and operation requirements of the production line and helps the enterprise optimize and upgrade its production process.

Perfect service and strong supply capacity

Full-process technical support

Since the initial stage of product design, ZHHIMG's professional technical team has been closely collaborating with photovoltaic enterprises, providing professional advice and technical solutions. After the product is delivered, we also provide customers with comprehensive technical support, including equipment installation guidance, commissioning assistance, and daily maintenance training, etc. If customers encounter problems during use, ZHHIMG can respond promptly. By providing online remote guidance or dispatching professional technicians to provide on-site services, problems can be solved in a timely manner to ensure that the production of photovoltaic enterprises is not affected. This full-process technical support service ensures that photovoltaic enterprises have no worries when using ZHHIMG granite products.

Strong supply capacity

Facing the large-scale production demands of the world's TOP 3 photovoltaic enterprises, ZHHIMG has a strong supply capacity. Its production base is equipped with advanced production facilities and has sufficient production capacity. It can supply up to 10,000 pieces of granite products every month, which can meet the needs of rapid expansion and large-scale production of photovoltaic enterprises. Meanwhile, ZHHIMG has established an efficient logistics and distribution system, cooperating with many well-known logistics enterprises. It can deliver products quickly and safely to photovoltaic enterprises around the world through various means such as sea, land and air transportation, ensuring the continuity of production for enterprises.

In conclusion, ZHHIMG brand granite, with its outstanding physical properties, strict quality control, strong customization capabilities, and complete service and supply system, perfectly meets the high-precision and high-stability demands of the world's TOP 3 photovoltaic enterprises for production equipment, making it the trusted and preferred choice for these industry leaders. It contributes significantly to promoting the high-quality development of the photovoltaic industry.

Post time: May-19-2025