In the world of ultra-precision manufacturing and metrology, stability is everything. Whether in semiconductor equipment, precision CNC machining, or optical inspection systems, even micron-level vibrations can compromise accuracy. This is where Granite Air Bearing Stages excel, offering unmatched stability and reliability for high-end industrial applications.

The Role of Granite in Precision Stages

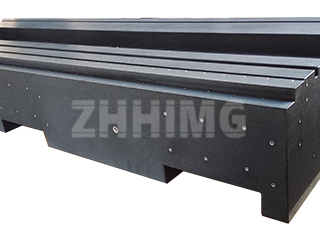

Granite is not just a premium material—it is a cornerstone of ultra-precision engineering. The ZHHIMG® Black Granite used in our air bearing stages has a high density (~3100 kg/m³) and excellent dimensional stability, making it superior to typical materials such as aluminum, steel, or even some imported granites. These physical properties reduce deformation under load, minimize thermal expansion, and provide a vibration-damping effect that is critical for precision stages.

Unlike metals, granite does not warp or bend easily under stress. Its homogeneous crystalline structure ensures uniform stiffness across the entire platform, allowing precision instruments to maintain alignment over time. In addition, granite’s natural damping properties absorb environmental vibrations, further enhancing stage stability.

Air Bearings: Frictionless Precision

The integration of air bearings on a granite base takes stability to a new level. Air bearings create a thin, uniform film of pressurized air between the stage and guideway, enabling near-frictionless motion. This eliminates stick-slip effects and reduces wear, which are common in traditional mechanical bearings. The result is ultra-smooth, vibration-free movement that is critical for applications requiring nanometer-level precision.

When mounted on a granite base, air bearings benefit from the material’s natural flatness and rigidity. Granite ensures that the air gap remains perfectly uniform, preventing tilt or uneven load distribution. This synergy between granite and air bearing technology is why ZHHIMG® Granite Air Bearing Stages are widely regarded as the benchmark for stability in ultra-precision equipment.

Thermal Stability and Environmental Advantages

Temperature changes can significantly impact precision stages, especially in high-accuracy environments like semiconductor fabs or optical measurement labs. Granite’s low thermal expansion coefficient minimizes dimensional changes with temperature fluctuations, maintaining the stage’s flatness and alignment. Combined with controlled-environment workshops, these stages deliver consistent performance even under challenging conditions.

Furthermore, granite’s resistance to chemical corrosion, wear, and fatigue ensures long-term reliability, even in demanding industrial environments. Unlike metal stages that may require frequent maintenance, granite air bearing stages maintain their precision over years of continuous operation.

Applications Across Industries

The unique combination of granite’s physical properties and air bearing technology makes these stages ideal for a wide range of applications:

-

Semiconductor Equipment: Wafer inspection, lithography, and coating processes

-

Precision CNC Machines: High-accuracy milling, drilling, and laser machining

-

Optical Metrology: Coordinate measuring machines (CMM), profilometers, and AOI systems

-

Research & Development: Universities and institutes conducting nano-scale experiments

In each application, the stability provided by granite air bearing stages directly translates to higher measurement accuracy, improved production quality, and reduced operational errors.

Why ZHHIMG® Granite Air Bearing Stages Stand Out

ZHHIMG® leverages decades of expertise in granite processing and ultra-precision engineering. Our granite stages are ground and assembled to nanometer-level flatness, and every air bearing stage is meticulously calibrated using world-class measurement instruments, including laser interferometers and electronic levels. This commitment to precision ensures that every ZHHIMG® stage delivers maximum stability, reliability, and performance.

In summary, the stability of granite air bearing stages is not just a marketing claim—it is the result of carefully engineered material properties, advanced air bearing design, and meticulous craftsmanship. For industries demanding ultra-precision, repeatable performance, and long-term reliability, ZHHIMG® Granite Air Bearing Stages set the global standard.

Post time: Sep-26-2025