When we walk through ancient buildings or precision manufacturing workshops, we often encounter a material that seems to defy time and environmental changes: granite. From the steps of historical monuments that have borne countless footsteps to the precision platforms in laboratories that maintain micron-level accuracy, granite components stand out for their remarkable stability. But what makes this natural stone so resistant to deformation, even under extreme conditions? Let’s explore the geological origins, material properties, and practical applications that make granite an indispensable material in modern industry and architecture.

The Geological Miracle: Howranite Forms Its Unyielding Structure

Beneath the Earth’s surface, a slow-motion transformation has been occurring for millions of years. Granite, an igneous rock formed from the slow cooling and solidification of magma, owes its exceptional stability to a unique crystalline structure developed during this prolonged formation process. Unlike sedimentary rocks, which are layered and prone to splitting, or metamorphic rocks, which may contain weak planes from pressure-induced recrystallization, granite forms deep underground where magma cools gradually, allowing large mineral crystals to grow and interlock tightly.

This interlocking crystalline matrix primarily consists of three minerals: quartz (20-40%), feldspar (40-60%), and mica (5-10%). Quartz, one of the hardest common minerals with a Mohs hardness of 7, provides exceptional scratch resistance. Feldspar, with its lower hardness but higher abundance, acts as the rock’s “backbone,” while mica adds flexibility without compromising strength. Together, these minerals form a composite material that resists both compression and tension forces far better than many man-made alternatives.

The slow cooling process not only creates large crystals but also eliminates internal stresses that can cause deformation in rapidly cooled rocks. When magma cools slowly, minerals have time to align themselves into a stable configuration, minimizing defects and weak points. This geological history gives granite a uniform structure that responds predictably to temperature changes and mechanical stress, making it ideal for precision applications where dimensional stability is critical.

Beyond Hardness: The Multifaceted Advantages of Granite Components

While hardness is often the first property associated with granite, its utility extends far beyond resistance to scratching. One of the most valuable characteristics of granite components is their low thermal expansion coefficient, typically around 8-9 x 10^-6 per °C. This means that even with significant temperature fluctuations, granite changes dimension minimally compared to metals like steel (11-13 x 10^-6 per °C) or cast iron (10-12 x 10^-6 per °C). In environments like machine shops or laboratories where temperatures can vary by 10-20°C daily, this stability ensures that granite platforms maintain their precision where metal surfaces might warp or distort.

Chemical resistance is another key advantage. Granite’s dense structure and mineral composition make it highly resistant to acids, alkalis, and organic solvents that would corrode metal surfaces. This property explains its widespread use in chemical processing plants and laboratories, where spills are inevitable. Unlike metals, granite does not rust or oxidize, eliminating the need for protective coatings or regular maintenance.

Non-magnetization is a critical feature in precision measurement applications. Unlike cast iron, which can become magnetized and interfere with sensitive instruments, granite’s mineral composition is inherently non-magnetic. This makes granite surface plates the preferred choice for calibrating magnetic sensors and manufacturing components where magnetic interference could compromise functionality.

The natural vibration damping properties of granite are equally impressive. The interlocking crystal structure dissipates vibrational energy more effectively than solid metal, making granite platforms ideal for precision machining and optical applications where even minute vibrations can affect results. This damping capacity, combined with high compressive strength (typically 150-250 MPa), allows granite to support heavy loads without resonant vibration or deformation.

From Ancient Temples to Modern Factories: The Versatile Applications of Granite

Granite’s journey from quarries to cutting-edge technology is a testament to its timeless utility. In architecture, its durability has been proven by structures like the Great Pyramid of Giza, where granite blocks have withstood over 4,500 years of environmental exposure. Modern architects continue to value granite not only for its longevity but also for its aesthetic versatility, using polished slabs in everything from skyscraper facades to luxury interiors

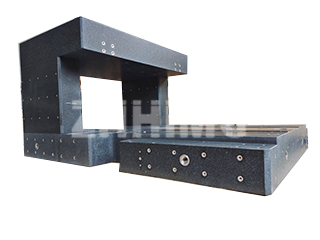

In the industrial sector, granite has revolutionized precision manufacturing. As reference surfaces for inspection and measurement, granite surface plates provide a stable, flat datum that maintains its accuracy over decades. The Granite and Marble Manufacturers Association reports that properly maintained granite platforms can retain their flatness within 0.0001 inches per foot for up to 50 years, far exceeding the lifespan of cast iron alternatives which typically require re-scraping every 5-10 years.

The semiconductor industry relies heavily on granite components for wafer inspection and manufacturing equipment. The extreme precision required for microchip production—often measured in nanometers—demands a stable base that won’t deform under vacuum conditions or temperature cycling. Granite’s ability to maintain dimensional stability at the sub-micron level has made it an essential material in this high-tech field.

Even in unexpected applications, granite continues to prove its worth. In renewable energy systems, granite bases support solar tracking arrays, maintaining alignment with the sun despite wind loads and temperature changes. In medical equipment, granite’s vibration-damping properties ensure the stability of high-resolution imaging systems like MRI machines.

Granite vs. Alternatives: Why Natural Stone Still Outperforms Man-Made Materials

In an age of advanced composites and engineered materials, one might wonder why natural granite remains the material of choice for critical applications. The answer lies in a unique combination of properties that is difficult to replicate synthetically. While materials like carbon fiber reinforced polymers offer high strength-to-weight ratios, they lack granite’s inherent damping capacity and resistance to environmental degradation. Engineered stone products, which combine crushed stone with resin binders, often fail to match the structural integrity of natural granite, particularly under thermal stress.

Cast iron, long used as a reference surface material, suffers from several drawbacks compared to granite. Iron’s higher thermal expansion coefficient makes it more susceptible to temperature-induced distortion. It also requires regular maintenance to prevent rust and must be re-scraped periodically to maintain flatness. A study by the American Society of Mechanical Engineers found that granite surface plates maintained their accuracy 37% better than cast iron plates over a 10-year period in typical manufacturing environments.

Ceramic materials offer some competition to granite, with similar hardness and chemical resistance. However, ceramics are often more brittle and prone to chipping, making them less suitable for heavy-load applications. The cost of high-precision ceramic components also tends to be significantly higher than that of granite, especially for large surfaces.

Perhaps the most compelling argument for granite is its sustainability. As a natural material, granite requires minimal processing compared to engineered alternatives. Modern quarrying techniques have reduced environmental impact, and granite’s longevity means that components rarely need replacement, reducing waste over the product lifecycle. In an era where material sustainability is increasingly important, granite’s natural origins and durability offer significant environmental advantages.

The Future of Granite: Innovations in Processing and Application

While granite’s fundamental properties have been appreciated for millennia, recent innovations in processing technology are expanding its applications and improving its performance. Advanced diamond wire saws allow for more precise cutting, reducing material waste and enabling more complex component geometries. Computer-controlled grinding and polishing systems can achieve surface finishes with flatness tolerances as tight as 0.00001 inches per foot, opening new possibilities in ultra-precision manufacturing.

One exciting development is the use of granite in additive manufacturing systems. While not printable itself, granite provides the stable base necessary for large-format 3D printers producing components with tight dimensional tolerances. The vibration damping properties of granite help ensure consistent layer deposition, improving the quality of printed parts.

In the renewable energy sector, researchers are exploring granite’s potential in energy storage systems. Its high thermal mass and stability make it suitable for thermal energy storage applications, where excess energy can be stored as heat and retrieved when needed. Granite’s abundance and low cost compared to specialized thermal storage materials could make this technology more accessible.

The data center industry is also discovering new uses for granite. With the increasing density of computing equipment, managing thermal expansion in server racks has become critical. Granite mounting rails maintain precise alignment between components, reducing wear on connectors and improving system reliability. The natural fire resistance of granite also enhances data center safety.

As we look to the future, it’s clear that granite will continue to play a vital role in technology and construction. Its unique combination of properties—developed over millions of years of geological processes—offers solutions to challenges that modern materials still struggle to address. From ancient pyramids to quantum computing facilities, granite remains a material that bridges the gap between nature’s slow perfection and humanity’s drive for precision and durability.

Conclusion: The Timeless Appeal of Earth’s Own Engineering Material

Granite components stand as a testament to nature’s engineering prowess, offering a rare combination of stability, durability, and versatility that has been valued for millennia. From the precision of laboratory instruments to the grandeur of architectural masterpieces, granite continues to prove its worth in applications where performance and longevity are paramount.

The secret to granite’s stability lies in its geological origins—a slow, deliberate formation process that creates an interlocking crystalline structure unmatched by most man-made materials. This natural architecture gives granite its exceptional resistance to deformation, thermal expansion, chemical attack, and wear, making it the material of choice for critical applications across industries.

As technology advances, we find new ways to harness granite’s properties and overcome its limitations through improved processing and design. Yet, the fundamental appeal of granite remains rooted in its natural origins and the millions of years that shaped its unique characteristics. In a world increasingly focused on sustainability and performance, granite offers a rare combination of environmental responsibility and technical superiority.

For engineers, architects, and manufacturers seeking materials that can withstand the test of time while delivering uncompromising performance, granite remains the gold standard. Its story is intertwined with human progress, from ancient civilizations that recognized its durability to modern industries that rely on its precision. As we continue to push the boundaries of technology and construction, granite will undoubtedly remain an essential partner in building a more precise, durable, and sustainable future.

Post time: Nov-06-2025