In the field of semiconductor manufacturing, the cleanliness of the cleanroom environment directly affects the yield rate of wafer production and the performance of chips. The world's TOP 5 wafer fabrication plants have all phased out traditional cast iron materials and switched to granite platforms. Behind this transformation lies the ultimate pursuit of a zero-pollution environment in cleanrooms. Granite platforms, with their own characteristics, have demonstrated unparalleled advantages in clean rooms and have become the new favorite of wafer fabrication plants.

The "fatal defect" of cast iron materials in clean rooms

Cast iron, as a traditional industrial material, once had certain advantages in mechanical properties, but it has many problems in the semiconductor cleanroom environment. Firstly, the surface microstructure of cast iron is not dense, with a large number of pores and tiny cracks that are invisible to the naked eye. During the daily operation of cleanrooms, these pores are highly prone to adsorbing dust, oil stains and various chemical pollutants, becoming hiding places for pollution sources. Once contaminants accumulate, during the precise operations of wafer manufacturing, they may fall off and adhere to the surface of the wafer, causing serious quality problems such as short circuits and open circuits in the chip.

Secondly, cast iron has relatively poor chemical stability. During the wafer manufacturing process, various corrosive chemical reagents such as hydrofluoric acid and sulfuric acid are used. Cast iron is prone to oxidation and corrosion reactions under the erosion of these chemical substances. The rust and metal ions produced by corrosion not only pollute the cleanroom environment but may also undergo chemical reactions with the materials on the wafer surface, damaging the physical and chemical properties of the wafers and significantly reducing the product yield.

The "zero-pollution" feature of granite platforms

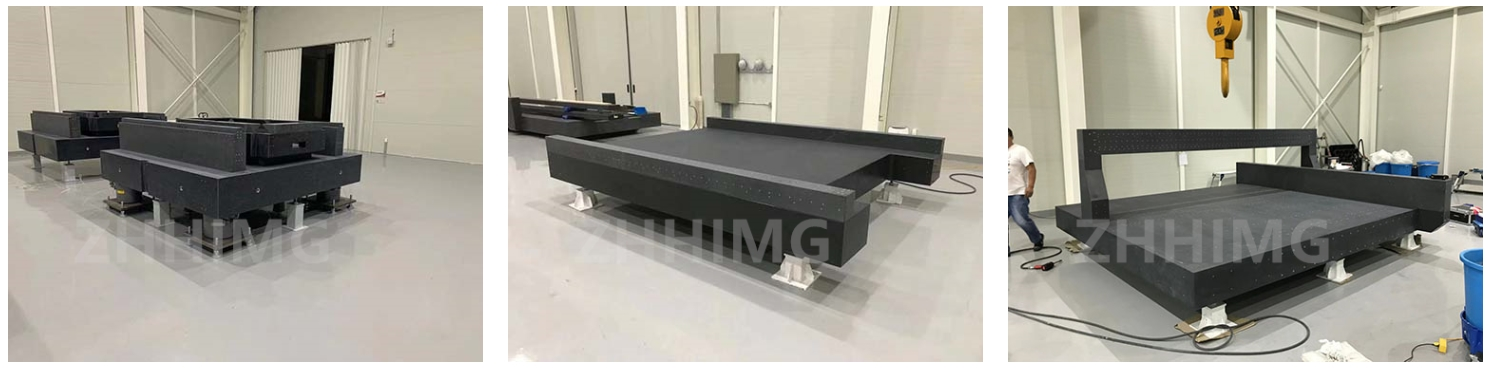

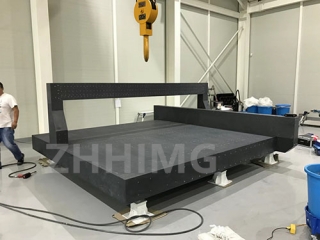

The reason why granite platforms are favored by the world's TOP 5 wafer fabrication plants lies in their inherent "zero-pollution" feature. Granite is a natural stone formed through geological processes over hundreds of millions of years. Its internal mineral crystals are closely crystallized, the structure is dense and uniform, and there are almost no pores on the surface. This unique structure ensures that it will not adsorb dust and contaminants. Even in the frequent air flow disturbances and personnel and equipment activities in the clean room, the granite platform surface can still remain clean, preventing the breeding and spread of contaminants.

In terms of chemical stability, granite performs exceptionally well. Its main components are minerals such as quartz and feldspar. It has extremely stable chemical properties and hardly reacts with any common chemical reagents. In the complex chemical environment of wafer manufacturing, granite platforms can handle the erosion of various corrosive reagents with ease, without generating corrosion products or metal ion pollution, providing a safe and clean basic platform for wafer production. Meanwhile, granite is non-conductive and does not generate static electricity, thus avoiding the risk of pollution caused by static electricity adsorbing dust particles and further ensuring the environmental quality of the clean room.

Material selection from the perspective of cost and benefit

Although the initial procurement cost of granite platforms is relatively higher than that of cast iron ones, in the long run, the comprehensive benefits they bring far exceed the cost difference. The frequent cleaning and maintenance of cast iron platforms due to pollution problems, as well as the huge losses caused by the increase in product defect rates, have kept the overall production costs high. The granite platform, with its zero-pollution advantage, significantly reduces the frequency of cleaning and maintenance in the clean room and the defect rate of products, lowers operating costs, and enhances production efficiency and product quality. Take a factory with an annual production capacity of one million wafers as an example. After adopting granite platforms, it can reduce losses caused by pollution by over ten million yuan each year, and the return on investment is very considerable.

The TOP 5 global wafer fabrication plants have abandoned cast iron and chosen granite platforms based on a comprehensive consideration of the requirements for cleanroom environments and production efficiency. The zero-pollution advantage of granite platforms provides a reliable guarantee for wafer production and drives semiconductor manufacturing towards higher precision and higher yield rates. With the continuous development of semiconductor technology, granite platforms are bound to play a more important role in future wafer manufacturing.

Post time: May-14-2025