The pursuit of accuracy is the bedrock of scientific discovery and advanced engineering. In the modern laboratory environment, especially those focused on demanding physical experiments like mechanics testing, material science, and vibration analysis, the base upon which the entire experiment rests is often the single most critical factor determining data integrity. The simple question, “Why is a Precision Granite Surface Plate the go-to solution?” uncovers a deep intersection of material science, metrology, and practical engineering.

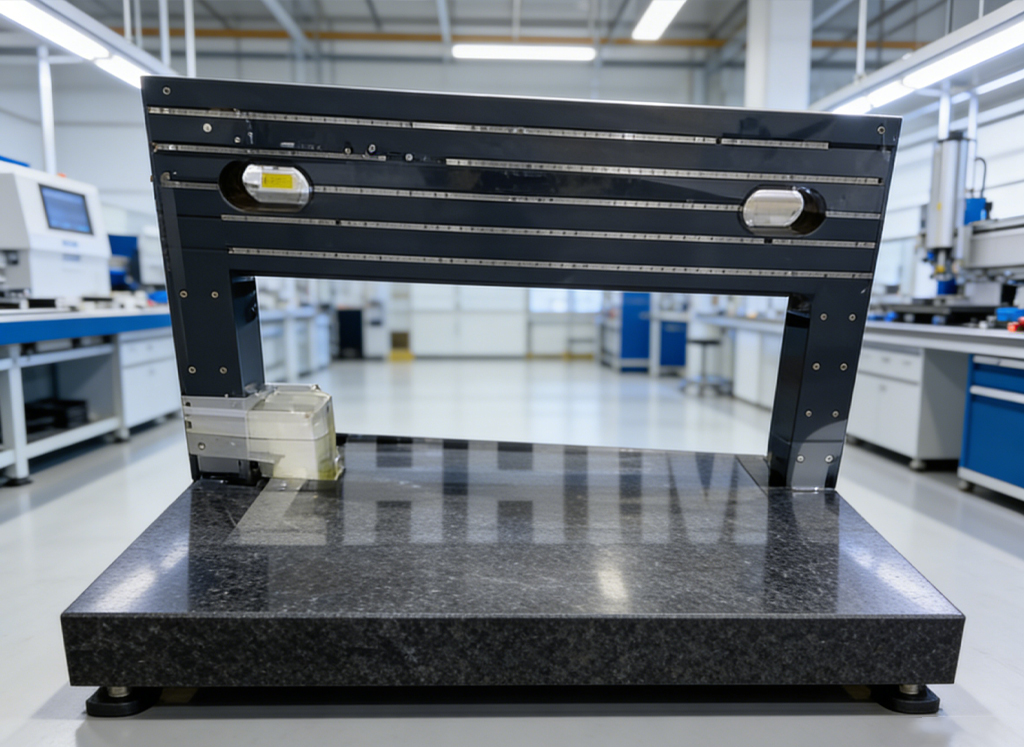

This is not merely a piece of polished stone; it is a meticulously engineered foundation, a benchmark for flatness, and a passive mechanical component that fundamentally enables ultra-precision metrology and reliable scientific testing.

The Problem of the Imperfect Base: Why Concrete Floors and Steel Tables Fail

Before delving into the attributes of granite, it is vital to understand the challenges inherent in using conventional laboratory surfaces. A standard steel workbench or a concrete floor, no matter how solid it appears, suffers from significant limitations when faced with micro-measurement, force application, or dynamic testing:

-

Vibration Transmission: Steel is highly resonant. Any environmental noise, foot traffic, or mechanical hum is easily transmitted and amplified across a steel table, introducing noise into sensitive force transducers or accelerometers during vibration testing. Concrete floors, while massive, still transmit low-frequency seismic and structural noise.

-

Thermal Instability: Metals (like steel or aluminum) have a relatively high coefficient of thermal expansion (CTE). Even small temperature fluctuations in a lab can cause the base to warp or expand measurably, instantly compromising the integrity of delicate alignments in mechanics testing setups.

-

Geometric Error (Flatness): Achieving true flatness across a large metal surface is costly and difficult to maintain due to internal stresses and manufacturing limitations. For experiments requiring the absolute calibration of leveling devices, height gauges, or optical instruments, this inherent geometric inaccuracy is a fatal flaw.

-

Magnetic and Electrical Interference: Many advanced instruments, particularly those utilizing eddy current sensors or high-sensitivity force gauges, are susceptible to magnetic or electrical fields, making ferromagnetic materials like steel tables unsuitable.

The Granite Solution: Material Science Meets Metrology

The adoption of ZHHIMG® Black Granite—specifically known for its high-density, superior physical properties—as the foundational material for Precision Granite Surface Plates directly addresses and resolves these limitations, making it the indispensable metrology tool for physical labs.

1. The Ultimate Reference Plane: Unmatched Geometric Accuracy

The primary function of a Granite Surface Plate is to serve as the perfect datum, a theoretical reference plane upon which all measurements are based.

-

Exceptional Flatness and Straightness: Through expert lapping and the skilled hands of master craftsmen—like those at ZHHIMG Group who achieve nanometer-level flatness—granite platforms meet the most stringent international standards (e.g., DIN, ASME, JIS). This level of certified accuracy is impossible to replicate consistently or cost-effectively with alternative materials.

-

Dimensional Stability: Granite is an isotropic material, meaning its properties are uniform in all directions, and it is free from the internal stresses common in machined metal. This stability ensures that the plate holds its geometric accuracy over decades of use, minimizing the need for constant, expensive recalibration.

2. Vibration Damping and Rigidity: Ensuring Clean Data

For experiments like vibration testing or dynamic material fatigue analysis, eliminating unwanted mechanical noise is paramount.

-

Superior Damping Coefficient: High-density granite, particularly the 3100 kg/m³ ZHHIMG® Black Granite, exhibits a high internal friction. This quality allows it to absorb mechanical energy and dissipate vibrations far faster and more effectively than steel or cast iron. The result is a clean, quiet mechanical ground, allowing sensors and force gauges to capture true experimental data without interference.

-

High Modulus of Elasticity (Rigidity): Despite its dampening capabilities, granite possesses high stiffness. This high rigidity minimizes deflection under the heavy loads often associated with mechanics testing frames, large optical equipment, or CMM (Coordinate Measuring Machine) systems. The lack of deflection under load is crucial for maintaining the critical alignment between testing apparatus and the material under investigation.

3. Thermal and Chemical Inertia: A Stable Environment

The laboratory environment is rarely perfectly controlled, making material responsiveness a critical concern.

-

Low Coefficient of Thermal Expansion (CTE): Granite’s low CTE means that even small temperature swings produce negligible dimensional changes, a stark contrast to metal which can expand or contract significantly. This passive thermal stability is key to reliable data capture over extended experimental periods.

-

Non-Hygroscopic and Non-Corrosive: Granite does not absorb moisture and is naturally resistant to corrosion from common laboratory chemicals and rust. This makes it ideal for use in varied environments, from high-humidity coastal labs to clean rooms, ensuring long-term functional and cosmetic integrity without the need for protective coatings.

-

Non-Magnetic: As a non-ferromagnetic material, granite is essential for setups involving magnetic sensors, linear motors, or sensitive electron beam equipment, eliminating the risk of magnetic interference that contaminates data.

ZHHIMG®: Setting the Global Standard for Precision

When selecting a Precision Granite Surface Plate for your laboratory, the manufacturing source is as important as the material itself. ZHONGHUI Group (ZHHIMG®) has solidified its position as a global leader by integrating world-class production capacity with decades of artisanal expertise.

Our commitment to the highest quality is demonstrated through:

-

Comprehensive Quality Certification: ZHHIMG® is the only company in the industry to hold concurrent ISO 9001, ISO 45001, ISO 14001, and CE certifications, providing a verifiable guarantee of quality, environmental responsibility, and occupational health and safety.

-

State-of-the-Art Facilities: Our 10,000 m² dedicated Constant Temperature and Humidity Workshop is a testament to our quality pledge. This facility, equipped with military-grade flooring and advanced anti-vibration features, is designed specifically to ensure that every surface plate and granite component leaves our factory certified to the highest possible standard, ready for immediate use in the most demanding ultra-precision industry applications.

-

Global Collaboration: Our ongoing partnerships with renowned institutions such as the National University of Singapore, Stockholm University, and various international metrology institutes (UK, France, US) reflect our continuous effort to refine measurement techniques and maintain absolute technical authority in the precision machining domain.

Beyond the Surface Plate: The Future of Precision Components

The principles that make the surface plate essential extend directly to our advanced Granite Components and Granite Machine Structures. Whether it is a highly rigid Granite Gantry Base for a semiconductor lithography machine or an integrated Granite Air Bearing assembly, these materials form the core of the ultra-precision industry. By providing a vibration-dampened, dimensionally stable base, ZHHIMG® enables engineers to push the boundaries of achievable accuracy in CMM equipment, laser processing systems, and high-speed inspection platforms.

Conclusion: Invest in Your Data Integrity

For any laboratory dedicated to mechanics testing, vibration testing, or any form of high-stakes physical experiment, a Precision Granite Surface Plate is not a luxury—it is a mandatory investment in data integrity. It provides the only practical and certifiable reference plane that can passively isolate the experiment from environmental noise while simultaneously ensuring geometric perfection. Choosing a certified provider like ZHHIMG® means opting for a globally trusted benchmark, backed by superior materials and an unwavering commitment to the maxim: “The precision business can’t be too demanding.”

Post time: Dec-16-2025