n the competitive world of Mold Manufacturing—especially for injection molds, stamping dies, and casting patterns used in automotive, medical device, and consumer electronics production—the margin for error has vanished. A flawless mold is the guarantee of millions of perfect final products. The entire mold making process, from initial computer numerical control (CNC) machining to final assembly, hinges on the ability to repeatedly verify and position components with micron-level precision. This foundational requirement explains why the Precision Granite Surface Plate is not just a tool, but the essential, uncompromised reference datum for the industry.

The role of the granite platform in this sector extends far beyond simple surface inspection; it serves as the ultimate arbiter of geometric accuracy, enabling quality engineers to certify the dimensional integrity of critical mold components, ensuring interchangeability and flawless mating between the mold halves.

The Challenge of Mold Manufacturing: Geometric Integrity at High Speed

Mold components, such as cavities, cores, and complex slides, often feature intricate 3D geometries, tight tolerances, and highly polished surfaces. Any failure in the mold structure—be it misalignment, non-parallelism, or incorrect depth—will translate directly into defects in every subsequent part produced, leading to catastrophic production losses.

Traditional measuring bases made of steel or cast iron struggle to maintain the required stability due to factors like residual stress, thermal responsiveness, and insufficient vibration damping. Mold makers need a metrology tool that offers:

-

Absolute Flatness: A certified reference plane against which all heights, depths, and angles can be checked.

-

Dimensional Stability: A material that remains unaffected by the temperature fluctuations of the workshop floor.

-

Vibration Isolation: A solid base that prevents environmental disturbances from affecting sensitive measurement instruments like dial indicators, electronic levels, or CMM probes.

Granite’s Indispensable Role: Accuracy and Assembly

The Precision Granite Surface Plate addresses these challenges through two primary functions in the mold shop: Mold Accuracy Inspection and Critical Base Positioning.

1. Mold Accuracy Inspection: The True Datum for Quality

When inspecting the various components that make up a mold set, the granite plate provides the certified, unwavering zero-reference plane:

-

Dimensional Verification: High-density granite, such as the ZHHIMG® Black Granite (with a density of approximately 3100 kg/m³), offers superior rigidity, ensuring the plate does not deflect under the weight of large or heavy mold bases. This allows quality assurance personnel to accurately verify parallelism, squareness, and flatness using height gauges, electronic levels, and gauge blocks. The material’s high internal damping further ensures that environmental vibrations do not interfere with sensitive measurement readings.

-

Optical and CMM Reference: The plate is the mandated foundation for all high-precision equipment used in Mold Precision Detection, including Coordinate Measuring Machines (CMM Equipment), vision systems, and specialized inspection jigs. The flatness of the granite base directly dictates the overall accuracy of the CMM, making the use of certified Grade 00 or calibration-grade plates non-negotiable for high-tolerance mold work.

-

Thermal Inertia for Reliability: As the mold components themselves cool down from the CNC Machining process, they contract. The granite’s extremely low Coefficient of Thermal Expansion (CTE) ensures that the reference base itself remains dimensionally constant, providing a stable platform for tracking and measuring the part’s cooling-related dimensional changes accurately.

2. Base Positioning and Component Assembly: Building Perfection

The quality of a mold is ultimately determined by how perfectly its complex components—cores, cavities, runners, and ejector pins—align during assembly. The granite plate facilitates this crucial step:

-

Reference for Alignment: In the final stages of mold assembly, components are often temporarily placed on the Granite Platform to check the vertical and lateral alignment before final bolting. Specialized Granite Components like squares, parallels, and V-blocks, which are ground to the same sub-micron accuracy as the plate itself, are used to hold complex parts perpendicular or parallel to the datum plane, ensuring the flawless mating of the two mold halves.

-

Scraping and Fitting: For older or specialized precision molds that require manual scraping or fitting to achieve optimal contact, the granite plate provides a superior reference surface for transferring high-spots onto the mold component using bluing compound. The material’s inherent flatness and hardness ensure that the transfer process is clean and highly accurate.

-

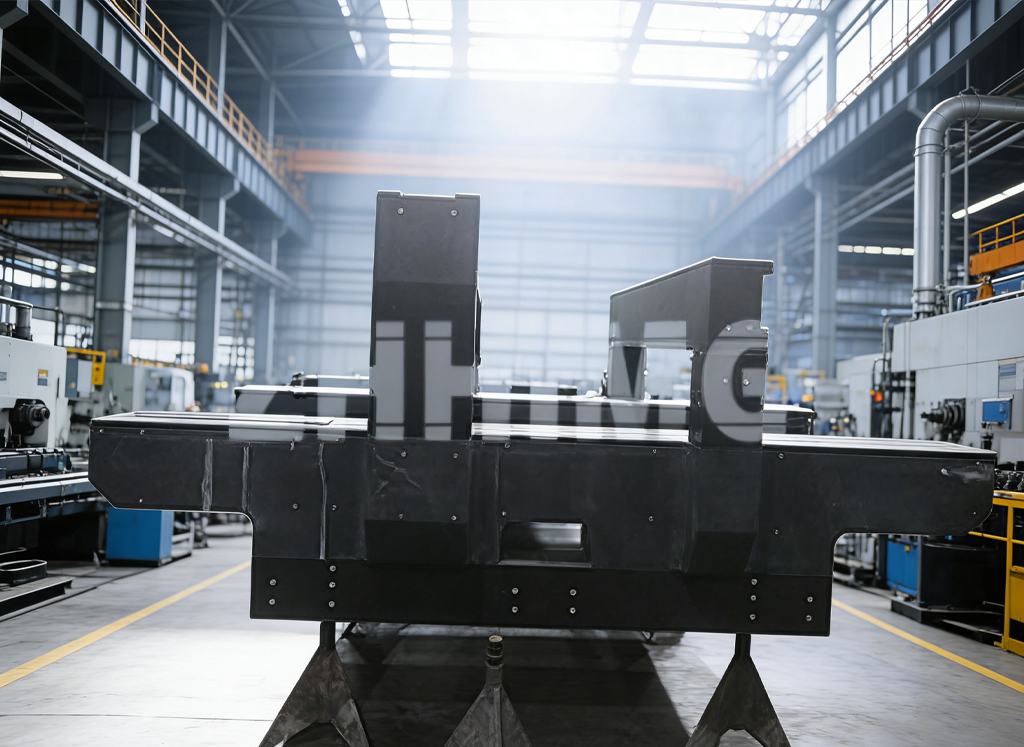

Custom Fixturing Bases: Beyond standard plates, custom-engineered Granite Machine Structures and bases are used as mounting platforms for precision assembly jigs. These specialized Granite Assemblies provide a dimensionally stable structure that resists warpage and vibration, enabling assemblers to achieve the tight stack-up tolerances required for high-cavitation and multi-level molds.

The ZHHIMG® Difference: A Partner in Precision Mold Making

For an industry where speed and precision are paramount, choosing a Precision Granite Manufacturer with global authority and unparalleled capacity is key. ZHONGHUI Group (ZHHIMG®) elevates the standard of Granite Metrology Tools through:

-

Certified Excellence: As the only company in the industry holding the concurrent ISO 9001, ISO 45001, IS

14001, and CE certifications, we demonstrate a systemic commitment to quality that aligns with the highest standards demanded by the mold manufacturing supply chain.

14001, and CE certifications, we demonstrate a systemic commitment to quality that aligns with the highest standards demanded by the mold manufacturing supply chain. -

Unrivaled Manufacturing Scale: Our capability to process massive granite components—including single units up to 100 tons—and our high-speed production lines ensure that we can supply the large, complex, and high-volume Granite Bases required by the global automotive and electronics mold industries without compromise.

-

The Pursuit of Perfection: Guided by the commitment, “No cheating, No concealment, No misleading,” and the quality policy, “The precision business can’t be too demanding,” every platform is finished in our 10,000 m² Constant Temperature and Humidity Workshop, guaranteeing its certified accuracy before it reaches your facility.

The complexity of modern mold making requires tools that are inherently simple, stable, and absolutely reliable. The Precision Granite Surface Plate is the foundational tool that provides the geometric truth needed to transform digital designs into physical perfection, securing the quality and longevity of every mold produced.

Post time: Dec-16-2025