In the realm of high-precision optical measurement and imaging, the margin for error has effectively vanished. We are no longer living in a world of millimeters or even micrometers; today’s leading-edge researchers and industrial engineers are operating in the nanometer scale. Whether it is the alignment of a high-power laser system, the sub-atomic resolution of an electron microscope, or the delicate calibration of an interferometer, the enemy is always the same: instability.

Even the most sophisticated optical sensor is only as good as the platform it sits upon. If the base vibrates, the data drifts. If the temperature fluctuates, the geometry shifts. This pursuit of “absolute stillness” has led the industry away from traditional metallic structures and toward a material forged over millions of years of geological pressure: granite. At ZHHIMG (ZhongHui Intelligent Manufacturing), we have witnessed a global shift where granite is no longer just an alternative—it is the gold standard. But what is it about this natural igneous rock that makes it so indispensable for the next generation of optical technology?

The Silent Guardian: Understanding the Science of Vibration Damping

One of the most significant challenges in any optical laboratory or semiconductor cleanroom is ambient vibration. This noise can come from anywhere—HVAC systems, heavy machinery in a nearby wing, or even the subtle seismic activity of the earth itself. While steel and cast iron have been the backbone of industrial machinery for centuries, they possess a fundamental flaw in the context of optics: they ring.

When a metal structure is subjected to an external force, the energy tends to resonate through the material with very little resistance. This resonance creates a “noise floor” that masks the delicate signals being captured by optical instruments. Granite, by contrast, possesses a remarkably high internal damping coefficient. Because of its dense, non-homogeneous crystalline structure, kinetic energy is rapidly absorbed and dissipated as trace amounts of heat rather than being allowed to travel through the component as mechanical vibration.

When you mount a laser interferometer on a ZHHIMG precision granite base, you are essentially decoupling the instrument from the chaotic environment surrounding it. This natural damping ensures that the “settling time” of a system—the time it takes for a movement to stop vibrating—is drastically reduced. For high-speed imaging and automated inspection, this translates directly into higher throughput and more reliable data.

Thermal Inertia and the Battle Against Expansion

Precision is often a victim of the thermometer. In many industrial environments, temperature fluctuations are inevitable. While a human might not notice a change of half a degree, a high-precision optical bench certainly will. Most metals have a relatively high coefficient of thermal expansion (CTE). As the room warms, the metal grows; as it cools, it shrinks. In a long-path optical system, even a tiny change in the length of the support structure can throw a beam out of alignment or introduce spherical aberration into an image.

Granite offers a level of thermal stability that metals simply cannot match. Its low CTE ensures that the geometric integrity of the support structure remains constant over a wide range of operating temperatures. Furthermore, because granite is a poor conductor of heat, it possesses high thermal inertia. It does not react impulsively to a sudden gust of air from an air conditioner or the heat generated by a nearby electronic component. Instead, it maintains a steady state, providing a predictable environment for the optical path.

This thermal “laziness” is exactly what engineers look for when designing long-term experiments or 24/7 industrial monitoring systems. By choosing a granite component from ZHHIMG, designers are effectively “baking in” a layer of environmental resistance that would otherwise require expensive and complex active thermal compensation systems.

The Advantage of Geological Time: Dimensional Stability and Longevity

One of the most overlooked aspects of material selection is internal stress. When a metal component is cast, forged, or welded, it retains significant internal stresses. Over months or years, these stresses gradually “relax,” causing the component to warp or creep. This is a nightmare for optical systems that require alignment to be maintained over the lifetime of the product.

Granite is a material that has already spent millions of years under the earth’s crust. It is naturally aged and geologically stable. When we process a block of granite at ZHHIMG, we are working with a material that has no “memory” of past stresses. Once it is lapped to a specific flatness or squareness, it stays that way. This long-term dimensional stability is why granite is the material of choice for the world’s most accurate Coordinate Measuring Machines (CMMs) and why it is now dominating the optical (instrument stand) market.

Furthermore, the physical hardness of granite—typically rated high on the Mohs scale—means it is incredibly resistant to scratches and wear. Unlike an aluminum or steel surface that might develop burrs or dents over time, a granite surface remains pristine. This durability ensures that the mounting interfaces for optical components remain perfectly flat, year after year, protecting the initial investment of the equipment owner.

Bridging the Gap Between Nature and High-Tech Integration

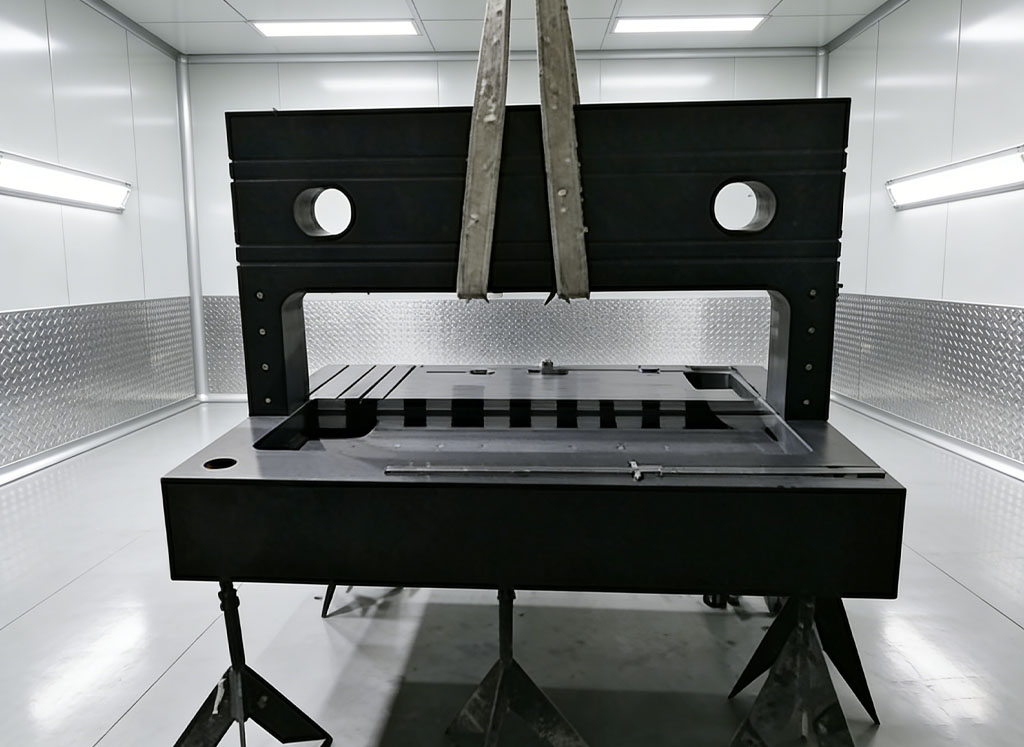

There is a common misconception that granite is a “low-tech” material because it is stone. In reality, the integration of granite into modern optical systems is a feat of advanced engineering. At ZHHIMG, we utilize state-of-the-art diamond tooling and precision lapping techniques to achieve surface accuracies that are measured in fractions of a micron.

Modern optical stands often require more than just a flat surface; they need integrated threaded inserts for mounting, T-slots for modularity, and even internal channels for cabling or cooling. We have perfected the art of “hybridizing” granite—combining the raw physical advantages of the stone with the versatility of precision-machined metal inserts. This allows researchers to have the stability of a mountain with the convenience of a breadboard.

Another hidden advantage is the non-magnetic and non-conductive nature of the material. In experiments involving sensitive photonics or electron beam lithography, electromagnetic interference (EMI) can be a dealbreaker. Metal supports can sometimes act as antennas or create eddy currents that interfere with the electronics. Granite is completely inert. It does not rust, it does not conduct electricity, and it is entirely unaffected by magnetic fields. This makes it the ideal partner for the most sensitive “clean” environments in physics and biotechnology.

How Granite Empowers the Future of Industrial Inspection

As we look toward the future, the demands on optical systems are only going to increase. The semiconductor industry is moving toward 2nm processes, and the medical field is pushing the boundaries of live-cell imaging. In these scenarios, the “support structure” is no longer a passive component; it is an active enabler of performance.

When a company selects a ZHHIMG granite solution, they are choosing to eliminate a major variable from their error budget. By reducing the noise floor, stabilizing the thermal profile, and ensuring lifetime accuracy, granite allows the optical sensors to perform at their theoretical limits. This is why you will find our components in the heart of the world’s most advanced laser labs, aerospace testing facilities, and high-end manufacturing plants.

In a market where “good enough” no longer suffices, the question isn’t whether you can afford to use granite—it’s whether you can afford the cost of the instability that comes with anything else. The natural properties of granite, refined by human precision, offer a foundation that is as close to “absolute zero” in terms of mechanical interference as modern science allows.

Why ZHHIMG is the Trusted Partner for Global Leaders

At ZHHIMG, we pride ourselves on being more than just a supplier; we are a partner in precision. We understand that every optical system has a unique personality and a specific set of challenges. Our role is to take the raw power of natural granite and shape it into a solution that meets the rigorous demands of the European and American markets.

Our commitment to quality, combined with our deep understanding of material science and SEO-ready transparency, ensures that our clients receive components that are not only world-class but also ethically sourced and masterfully engineered. We don’t just provide a base; we provide the peace of mind that allows scientists and engineers to focus on their discoveries rather than their vibrations.

Post time: Dec-23-2025