In the high-stakes world of precision manufacturing, where a single micron deviation can ruin an entire production run, the choice of workbench surface becomes a make-or-break decision. On October 15, 2025, a leading aerospace component manufacturer reported a staggering $2.3 million loss after a cast iron workbench failed to maintain stability during critical turbine blade inspections. What makes this incident particularly noteworthy? The failure was traced to thermal expansion causing just 42 microns of distortion—less than the width of a human hair—across a 2-meter surface. This disaster highlights an often-overlooked cornerstone of manufacturing excellence: granite flatness.

The Hidden Cost of Inaccurate Work Surfaces

Manufacturing facilities worldwide lose an estimated $12 billion annually to errors stemming from inadequate workbench surfaces, according to a 2025 study by the International Precision Metrology Association. In semiconductor manufacturing, where 3nm node chips require nanometer-level precision, the consequences of subpar surface plates are even more dire. A European chipmaker recently documented a 1.2% increase in defect rates—translating to 12,000 faulty wafers monthly—after switching to lower-cost cast iron alternatives.

“Our calibration records showed the cast iron plates were drifting up to 8 microns weekly,” explains Dr. Elena Zhang, materials scientist at Unparalleled® Group’s R&D center. “What many manufacturers fail to realize is that granite isn’t just a premium option—it’s often the most cost-effective solution when total lifecycle costs are considered.”

Why Granite Outperforms All Alternatives

Granite’s superiority stems from millions of years of natural formation followed by precision engineering. The material’s inherent properties address three critical challenges in precision manufacturing:

Thermal Stability That Defies Temperature Fluctuations

Granite’s coefficient of thermal expansion (CTE) measures a mere 4.6×10⁻⁶/°C—approximately one-third that of steel and one-quarter that of aluminum. This means a 1°C temperature change across a 2-meter granite surface plate causes just 9.2 microns of expansion, compared to 42 microns for cast iron. In controlled environments like semiconductor fabs, this stability translates directly to measurable improvements in yield rates.

Vibration Damping That Protects Microscopic Measurements

In an industry where cutting tools operate at 30,000 RPM, vibration control is paramount. Granite’s natural damping properties absorb mechanical vibrations 3-5 times more effectively than metal surfaces, according to testing at Germany’s Fraunhofer Institute. This characteristic proved decisive for a medical device manufacturer that reduced tool wear by 2.8 times after upgrading to granite workbenches.

Unrivaled Wear Resistance for Decades of Service

With a Mohs hardness rating of 6-7, granite resists scratches and indentations far better than steel or aluminum. A 2024 study by the American Society of Mechanical Engineers found that properly maintained granite surface plates retain 98% of their original flatness after 15 years of continuous use, compared to 72% for cast iron alternatives.

Understanding Precision Grades: From Workshop to Laboratory

The ISO 8512-2:1990 standard establishes four accuracy grades for granite surface plates, each serving distinct manufacturing needs:

Grade 00 (Laboratory Standard)

With a maximum flatness tolerance of 0.005 mm/m, these plates are the gold standard for calibration labs and semiconductor inspection. A 1000×600mm Grade 00 plate from Zhonghui Group typically costs $2,500-$4,000 but eliminates errors that could cost exponentially more downstream.

Grade 0 (Precision Inspection)

At 0.01 mm/m tolerance, these plates suit most manufacturing quality control applications. Automotive suppliers report reducing rework rates by 17% after upgrading from Grade 1 to Grade 0 surfaces.

Grade 1 (General Workshop Use)

With a 0.02 mm/m tolerance, these represent the entry point for precision manufacturing. Smaller 300×200mm Grade 1 plates start around $350, making them economical for basic inspection tasks.

Grade 2 (Rough Operations)

While rarely used in precision settings, these plates find applications in heavy fabrication where extreme flatness isn’t critical.

The Economics of Granite: Short-Term Cost vs. Long-Term Value

A comprehensive cost analysis by McKinsey & Company revealed that granite surface plates deliver a 22% lower total cost of ownership over 10 years compared to cast iron alternatives. This calculation includes:

- Initial purchase price (30-50% higher for granite)

- Annual calibration costs (60% lower for granite)

- Maintenance expenses (negligible for granite vs. $350/year for cast iron rust prevention)

- Replacement frequency (15-20 years for granite vs. 5-7 years for cast iron)

“Many procurement teams focus solely on upfront cost,” notes Zhang. “But when you factor in that a quality granite plate maintains accuracy for decades with minimal maintenance, the ROI becomes undeniable.”

Making the Right Choice for Your Application

Selecting the optimal granite surface plate requires balancing three factors: accuracy requirements, workspace dimensions, and budget constraints. Zhonghui Group recommends:

Semiconductor & Optics Manufacturing

Grade 00 plates with custom T-slots for fixturing, paired with vibration isolation mounts. The company’s 1500×1000mm model, priced at $5,200, includes ISO 17025 calibration certification.

Aerospace Component Inspection

Grade 0 plates with integrated spirit levels and steel support frames. A 2000×1500mm configuration typically costs $7,800 but provides the stability needed for turbine blade measurements.

General Precision Machining

Grade 1 standard sizes (630×400mm starting at $1,250) offer the best balance of performance and value for CNC shops and toolrooms.

The Future of Granite Technology

Innovation continues to push granite’s capabilities further. Recent advancements include:

Nanostructured Surface Treatments

Companies like Zhonghui have developed proprietary finishing processes that reduce surface roughness to Ra 0.02μm—approaching optical quality while maintaining durability.

Composite Reinforcements

Steel-granite hybrid structures combine granite’s stability with metal’s flexibility for specialized applications like coordinate measuring machine bases.

Smart Monitoring Systems

Embedded sensors now provide real-time flatness monitoring, with wireless data transmission to quality management systems—a $1,500 option that pays for itself in reduced calibration downtime.

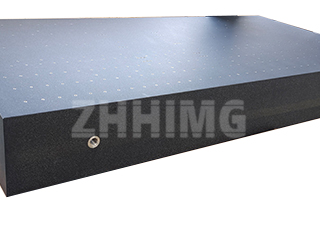

Why Leading Manufacturers Choose Zhonghui Granite

With over 25 years of experience and ISO 9001 certification, Zhonghui Group has established itself as the premier supplier of precision granite solutions. The company’s advantages include:

- Exclusive “Jinan Black” granite with 3100 kg/m³ density for superior stability

- In-house calibration laboratory accredited to ISO/IEC 17025

- Custom fabrication capabilities for sizes up to 7000×4000mm

- Comprehensive after-sales support including on-site installation

“Our German customers initially questioned why they should import from China,” recalls Zhang. “Then they saw our granite outperformed European varieties by 12% in thermal stability tests. Now we supply 14 automotive OEMs across Germany alone.”

The Sustainable Choice for Modern Manufacturing

Beyond performance benefits, granite represents a more environmentally responsible choice. The material requires minimal processing compared to engineered alternatives and boasts a carbon footprint up to 74% lower than synthetic stone surfaces, according to a 2025 study by the Natural Stone Institute.

“At a time when manufacturers face increasing pressure to reduce environmental impact, granite delivers on both performance and sustainability,” notes Zhang. “Our lifecycle analysis shows natural stone surfaces reduce CO₂ emissions by an average of 21.4 kg/m² compared to precast concrete alternatives.”

Invest in Precision, Invest in Profitability

The data is clear: granite surface plates aren’t luxury equipment—they’re essential tools for manufacturers competing in precision-critical industries. As tolerances shrink and quality requirements tighten, the decision to invest in proper workbench surfaces becomes increasingly decisive.

“Our customers consistently report 15-20% improvements in first-pass yields after upgrading to our granite plates,” says Zhang. “In today’s manufacturing environment, that’s not just an advantage—that’s survival.”

For companies ready to transform their quality control processes, Zhonghui Group offers free technical consultations and sample flatness testing. Visit www.zhhimg.com to request a personalized quote.

In the precision manufacturing revolution, your workbench surface isn’t just a platform—it’s the foundation of your competitive edge. Choose wisely, choose granite, and watch your accuracy—and profitability—reach new heights.

Post time: Dec-04-2025