The relentless march of miniaturization across industries—from semiconductor fabrication to advanced printed circuit boards (PCBs) and micro-mechanics—has amplified the need for exceptionally precise and repeatable dimensional metrology. At the core of this revolution lies the Automatic Line Width Measuring Equipment, a critical tool for quality control and process optimization. These sophisticated systems move far beyond simple optical inspection, relying on cutting-edge non-contact sensors, advanced algorithms, and, perhaps most critically, a foundation of mechanical stability that often goes unnoticed: granite mechanical components.

The overall performance of any high-speed, high-accuracy measuring instrument is a direct function of its constituent parts. While the optics, cameras, and processing software capture the attention, the stability of the physical platform—the very structure holding the sensors in precise alignment—is what determines the ultimate precision achievable. This is where the engineering choice of the Automatic Line Width Measuring Equipment mechanical components becomes paramount, leading many leading manufacturers to select granite as the material of choice for bases, columns, and air-bearing stages.

The Critical Role of Mechanical Stability in Metrology

Precision line width measurement often involves detecting dimensions in the micrometer and even sub-micrometer range. At this scale, even minute environmental fluctuations or structural imperfections can introduce unacceptable measurement errors. A core challenge for any automated system is maintaining the spatial relationship between the measurement sensor (often a high-resolution camera or laser micrometer) and the part being measured. This delicate relationship is highly vulnerable to several physical phenomena: vibration, thermal expansion, and structural drift.

Traditional materials like steel or aluminum, while strong, possess inherent limitations when pushed to the limits of metrological accuracy. They are excellent conductors of heat, making them susceptible to rapid and uneven thermal expansion from changes in ambient temperature or internal machine heat. Moreover, their relatively low damping capacity means they transmit and sustain vibrations, whether from internal motors, air compressors, or nearby factory machinery, translating into microscopic movement during the critical measurement cycle.

Granite: A Natural Solution for Ultra-Precision

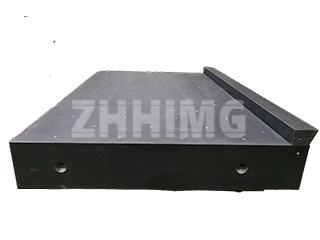

The shift to Automatic Line Width Measuring Equipment granite mechanical components is a deliberate engineering decision based on the material’s unique set of physical properties that make it an ideal foundation for high-precision metrology.

One of granite’s most significant advantages is its remarkably low coefficient of thermal expansion (CTE). Compared to steel, granite expands and contracts at a far slower rate and to a much lesser degree when exposed to temperature variations. This intrinsic thermal stability is essential for maintaining a constant geometric configuration of the equipment, ensuring that a calibration performed in the morning remains valid throughout the day, even as the factory environment shifts.

Furthermore, granite possesses an outstanding vibration damping capacity. Its natural crystalline structure acts as an exceptional absorber of mechanical energy. By dissipating vibrations quickly, a granite base minimizes the high-frequency oscillations that can blur optical readings or compromise the positional accuracy of the high-speed motion stages integral to the Automatic Line Width Measuring Equipment. This high damping factor allows the equipment to achieve faster measurement throughput without sacrificing the resolution and accuracy required for leading-edge manufacturing processes.

Another compelling feature is granite’s exceptional flatness and stiffness. Through specialized lapping and finishing processes, granite can achieve surface flatness tolerances in the sub-micrometer range, making it the perfect substrate for precision air-bearing systems that demand perfectly planar movement. This inherent stiffness ensures that the platform supporting the measuring axis resists deflection under the dynamic loads of the automated stages, guaranteeing the integrity of the reference plane during operation.

The Nexus of Motion Control and Granite

In a fully automated system, the work piece must be moved and positioned with extreme speed and accuracy. The Automatic Line Width Measuring Equipment relies on advanced components like linear motors and precision encoders, but these components are only as effective as the surface they operate on. A granite air-bearing stage, for instance, utilizes the stiffness and flatness of the granite to achieve frictionless, highly repeatable motion. By using the natural material properties for stability and pairing them with sophisticated motion control for agility, manufacturers create a synergy that drives unparalleled performance.

The precision engineering of the granite components themselves is a specialized field. Manufacturers must source high-quality black granite, which often features a higher density and lower porosity than other varieties, and then subject it to meticulous machining processes. The grinding, lapping, and polishing stages are often performed under stringent climate control to ensure the final product meets the extreme flatness and squareness tolerances necessary for world-class metrology.

Looking to the Future of Automated Measurement

As product geometries continue to shrink and manufacturing tolerances tighten, the demands placed on Automatic Line Width Measuring Equipment will only increase. The foundation laid by precision granite components is not merely a legacy choice; it is a future-proof necessity. The ongoing evolution of this technology will see the integration of more powerful multi-sensor arrays, higher magnification optics, and increasingly complex motion paths. In every case, the unwavering stability and thermal inertia provided by the granite mechanical components will remain the anchor for high-accuracy performance.

For any manufacturer operating in the competitive space of high-tech production, investing in measuring equipment with a robust, thermally stable granite core is not an extravagance—it is a strategic imperative to secure quality control, minimize yield loss, and maintain a competitive edge. The quiet strength of granite is what allows the sophisticated electronics and optics to perform their demanding task with consistent, uncompromised precision, truly making it the unsung hero of modern dimensional metrology.

Post time: Dec-03-2025