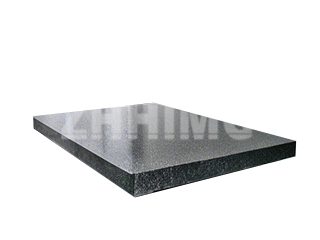

In the relentless pursuit of smaller, faster, and more powerful microchips, the demands placed on Wafer Processing Equipment are escalating to levels of precision previously deemed unattainable. As features shrink into the single-digit nanometer realm, the stability of the entire manufacturing platform becomes paramount. It is here, beneath the complex array of lasers, vacuum chambers, and robotic systems, that a material of ancient origin—natural granite—emerges as a decisive factor for modern semiconductor success. The specification, engineering, and supply of high-precision OEM granite components and the monolithic OEM granite machine bed are not just technical requirements; they are the bedrock of operational integrity.

The role of the machine base in any high-precision system is to provide a static, stable reference plane. In the volatile and accuracy-critical environment of semiconductor fabrication, where processes like lithography, etching, and deposition take place, tiny deviations—even at the sub-micron level—can lead to catastrophic yield loss. The choice of material for the primary structural elements, such as the Wafer Processing Equipment machine base, is therefore a non-negotiable step in design.

The Inherent Advantages of Natural Granite

Why does natural granite outperform engineered materials like cast iron, steel, or even certain composites in this highly specialized application? The answer lies in its unique, naturally aged physical properties that are perfectly suited for the unforgiving environment of precision machinery.

1. Exceptional Vibration Damping (Isolation from Process Dynamics):

Vibration is the nemesis of nanoscale manufacturing. Whether generated internally by motors and moving parts or externally from the cleanroom floor, any oscillation must be rapidly absorbed. Granite possesses an intrinsically high internal damping coefficient—significantly better than metals. This property means that mechanical energy is quickly dissipated as heat, preventing resonance and ensuring that critical processes are performed on a truly stationary platform. This is vital for maintaining the exact focal point in advanced lithography or ensuring uniform material removal during chemical mechanical planarization (CMP).

2. Near-Zero Thermal Expansion (Maintaining Alignment Integrity):

Wafer Processing Equipment often involves temperature fluctuations, both ambient and process-induced. Metallic materials expand and contract significantly with temperature changes, leading to thermal drift and misalignment of optical or mechanical systems. Granite, particularly black granite, exhibits an extremely low coefficient of thermal expansion (CTE), approximately 3×10⁻⁶/℃. This thermal stability ensures that the dimensional accuracy of the granite machine bed and other OEM granite components remains consistent, minimizing thermal errors and guaranteeing measurement repeatability under varying conditions.

3. Ultimate Flatness and Stiffness:

Through advanced lapping and polishing techniques, natural granite can achieve a surface flatness measured in sub-microns—an essential requirement for the reference surfaces used in precision motion control. Furthermore, its high Young’s modulus provides exceptional static and dynamic stiffness. This resistance to deflection under load is crucial, as the base must support massive linear motors, stages, and complex Wafer Processing Equipment assembly structures without measurable deformation, even over large spans.

Engineering the Future: OEM Granite Components and Complex Assembly

The modern application of granite extends beyond simple surface plates. Today’s high-tech manufacturers require complex, custom-designed OEM granite components. These can include air-bearing guide rails, intricate vacuum chucks, multi-axis stage elements, and mounting blocks for lasers and optics. These pieces are often machined with complex geometric features, including drilled holes for wire routing, threaded inserts for mounting, and precisely machined dovetails or slots for bearing systems.

The process of creating a full Wafer Processing Equipment assembly starts with the large granite machine bed. Subsequent granite components are precisely bonded or attached to it using advanced epoxy-based compounds, a critical step that ensures the entire structure acts as a single, homogenous unit. Successful integration demands meticulous attention to detail:

-

Customization: Components must be engineered precisely to the customer’s unique specifications, often including the integration of non-granite elements like cooling lines and sensor mounts directly into the structure.

-

Quality Assurance: Each component requires rigorous quality control, including flatness, straightness, and squareness verification using CMMs and laser interferometers, ensuring they meet the stringent ISO and international standards for metrology and precision.

-

Supplier Partnership: Choosing an OEM granite components supplier is a partnership. It requires an in-depth understanding of the semiconductor application, the ability to select the highest-grade raw stone, and the manufacturing capability to machine and assemble complex structures to nanometer tolerances.

In conclusion, while the finished microchip is a marvel of human ingenuity, its creation hinges on the silent stability provided by natural stone. The sophisticated application of granite as the core material for the granite machine bed and other specialized OEM granite components is an indispensable element in pushing the boundaries of miniaturization. For manufacturers of Wafer Processing Equipment, partnering with a specialist in high-precision granite structures is the first and most fundamental step toward securing a competitive edge in the global semiconductor market.

Post time: Dec-01-2025