In the field of modern manufacturing, precision is the benchmark of quality. The demand for micron-level accuracy in production has never been higher, driven by industries such as aerospace, electronics, automotive, and semiconductor manufacturing. Universal length measuring instruments are central to this precision, providing reliable measurements that ensure components meet stringent design specifications. Yet the performance of these instruments is not determined by their mechanics alone; the foundation they rest upon plays an equally critical role. This is where precision granite comes into play, offering unparalleled stability, durability, and accuracy for measurement and testing systems.

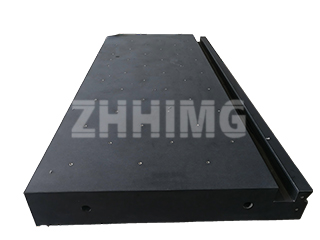

Precision granite for Universal length measuring instruments has become the material of choice for high-end metrology applications. Granite’s inherent physical properties—high density, low thermal expansion, and excellent wear resistance—make it ideal for supporting sensitive measurement equipment. A granite base ensures that the instrument maintains exact alignment and flatness over time, eliminating distortions caused by vibrations, temperature fluctuations, or mechanical stress. In practical terms, this means that every measurement taken reflects the true dimensions of the component being evaluated, which is crucial for maintaining quality standards in high-precision manufacturing environments.

One of the most demanding applications for precision granite is in nondestructive testing (NDT) systems. A nondestructive testing granite base provides a stable platform that supports high-precision inspections without introducing measurement errors. NDT methods, such as ultrasonic testing, X-ray inspection, or visual inspection using AOI Equipment, require a vibration-free and thermally stable foundation to accurately detect defects, material inconsistencies, or structural anomalies. Granite’s natural damping properties and resistance to deformation make it a perfect solution for these applications, ensuring that even the most subtle defects are detected reliably.

Granite rails for Universal length measuring instruments are another critical component in precision measurement systems. These rails guide moving parts of the instrument, such as measuring heads or scanning probes, with exceptional accuracy. The rigidity and stability of granite rails ensure that the motion of these components is consistent, reducing errors that can arise from mechanical flexing or thermal expansion. For industries that demand high throughput and repeatability, granite rails play an indispensable role in maintaining both efficiency and measurement integrity.

AOI Equipment, commonly used in electronics manufacturing for automated inspection of printed circuit boards, benefits significantly from granite-based platforms. Precision granite provides a stable, flat, and rigid surface that supports imaging systems and scanning sensors. By minimizing vibration and thermal distortion, granite ensures that AOI Equipment captures high-resolution images with accurate positional data. This is critical for detecting defects such as soldering errors, misaligned components, or micro-cracks, which could compromise the performance of high-end electronic products.

The advantages of precision granite extend beyond stability and flatness. Its wear resistance ensures long-term durability, reducing maintenance requirements and preserving measurement accuracy over years of use. Granite surfaces are also resistant to chemical corrosion and environmental degradation, making them suitable for a wide range of manufacturing and laboratory conditions. For engineers and quality control specialists, this translates into reliable measurement results, reduced downtime, and predictable maintenance cycles—key factors for operational efficiency and product quality assurance.

Integrating precision granite for Universal length measuring instruments, granite rails, and nondestructive testing bases with modern digital measurement systems enhances the overall capability of manufacturing facilities. Digital sensors, automated scanning, and real-time data acquisition systems rely on a stable and precise foundation to produce accurate results. Granite platforms eliminate many of the sources of error that could compromise digital measurements, ensuring that the data collected is both reliable and traceable. This integration supports modern quality management protocols and allows manufacturers to meet stringent international standards for measurement and inspection.

Furthermore, precision granite enables versatility in measurement and inspection workflows. From measuring linear dimensions and flatness to performing complex surface inspections and defect detection, granite-based instruments can adapt to various requirements without sacrificing accuracy. Granite rails provide smooth and precise motion control, while granite bases ensure that sensors and measuring heads remain perfectly aligned. The combination of these elements with universal length measuring instruments and AOI Equipment creates a comprehensive measurement ecosystem that supports both precision and efficiency.

Maintenance and proper handling of granite-based measurement systems are straightforward but essential. While granite is highly durable, keeping surfaces clean and free of particulate matter ensures optimal performance. Regular calibration and verification against certified standards maintain traceability and measurement reliability. By understanding the interaction between granite components and measurement instruments, engineers can maximize the lifespan of their equipment while maintaining the highest levels of precision.

The adoption of precision granite in universal length measuring instruments, nondestructive testing bases, granite rails, and AOI Equipment represents a strategic choice for manufacturers committed to excellence. It addresses critical challenges in measurement accuracy, stability, and long-term reliability. By investing in granite-based solutions, companies can ensure that their measurement and inspection processes deliver consistent, repeatable, and verifiable results, supporting high-quality production and customer satisfaction.

In conclusion, precision granite is more than just a material—it is the foundation of modern precision measurement and inspection. From universal length measuring instruments to AOI Equipment and nondestructive testing bases, granite provides the stability, accuracy, and durability that high-precision industries require. By integrating granite rails and bases into measurement systems, manufacturers can achieve superior accuracy, minimize errors, and maintain consistent quality across all processes. For any organization aiming to excel in precision engineering, understanding and implementing granite-based solutions is not optional—it is essential for long-term success.

Post time: Dec-02-2025