The semiconductor industry operates on a scale of precision that pushes the boundaries of human ingenuity. At the heart of this industry’s quality control—the final, critical step before a chip is deemed ready for market—lies a seemingly simple material: granite. Specifically, precision granite platforms are the go-to solution for semiconductor chip inspection, a fact that may surprise those outside the field. At ZHONGHUI Group (ZHHIMG®), we understand this relationship intimately. Our expertise in crafting ultra-high-precision granite components and measuring tools has made us a key partner to some of the world’s leading semiconductor and metrology companies. The reliance on granite for this critical application is not a matter of tradition but of pure physics and engineering. It’s about meeting a set of unique and demanding requirements that no other material can satisfy as effectively.

The Unyielding Demand for Stability

Semiconductor chip inspection is not just about checking for defects; it’s about verifying that microscopic features, often measured in nanometers, are perfectly formed. This process involves sophisticated equipment, such as optical inspection systems (AOI) and industrial CT scanners, which must remain perfectly stable during a scan. Any vibration, thermal expansion, or structural drift can introduce errors, leading to false positives or, worse, missed defects.

This is where granite shines. Unlike metal, which expands and contracts significantly with temperature changes, granite has an incredibly low coefficient of thermal expansion. Our ZHHIMG® Black Granite has a density of approximately 3100kg/m3, providing exceptional thermal stability. This means that a granite platform will maintain its shape and flatness even in environments where ambient temperature fluctuates slightly. In a climate-controlled workshop like our 10,000m2 facility, where temperature is maintained with military precision, granite’s stability is unmatched.

Furthermore, granite’s superior damping properties are essential. It naturally absorbs and dissipates mechanical vibrations, preventing them from being transferred to the delicate inspection equipment. In a busy manufacturing plant filled with machinery, this vibration dampening is critical to maintaining the integrity of the measurement. Our workshops are designed with this in mind, featuring ultra-thick concrete floors and anti-vibration trenches to create an environment where our craftsmen can achieve nanometer-level precision in their work.

The Quest for Absolute Flatness

For a chip inspection system to work, its base must be as close to perfectly flat as possible. The concept of a “flat surface” in this context is not visual but mathematical, measured with instruments like Renishaw laser interferometers and Swiss Wyler electronic levels. A chip inspector’s goal is to measure the flatness of a chip to a few microns, or even nanometers. To do this, the platform itself must be orders of magnitude flatter.

Granite is a material that, through our specialized hand-lapping techniques, can be ground to a level of flatness that is virtually unparalleled. Our master craftsmen, many of whom have over 30 years of experience, possess a tactile sense that allows them to “feel” a flatness deviation of just a few microns. This human touch, combined with our world-class equipment, allows us to produce granite surface plates with nanometer-level flatness, making them the ideal reference plane for calibration and inspection. This is the foundation upon which accurate semiconductor inspection is built.

Addressing Unique Semiconductor Industry Demands

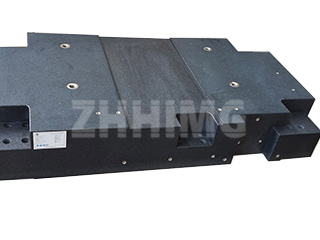

The semiconductor industry also has specific needs beyond stability and flatness. For example, many inspection systems use air bearings for frictionless movement. Granite is an excellent medium for air bearing guideways due to its inherent rigidity and a porosity that allows for fine, uniform air flow. Our granite air bearings are custom-machined to ensure smooth, precise motion, which is essential for high-speed, high-accuracy inspection.

Additionally, our ZHHIMG® Black Granite is non-magnetic and non-conductive, which is crucial for sensitive electronic components. It doesn’t interfere with the electromagnetic fields of the testing equipment or the chip itself. This neutrality is a feature that many metal platforms simply cannot offer.

At ZHHIMG®, we are not just selling granite. We are providing a critical foundation for the world’s most advanced technology. Our Commitment to Customers is to provide solutions that are No cheating, No concealment, No misleading. We work closely with our partners, including giants like Samsung and metrology institutions, to ensure our products not only meet their specifications but also contribute to the advancement of their technology. In the high-stakes game of semiconductor manufacturing, ZHHIMG®’s precision granite platforms are a silent, unmoving force, providing the stability and accuracy that bring tomorrow’s innovations to life.

Post time: Sep-28-2025