The Invisible Challenge in High-Precision Measurement

In the world of advanced manufacturing, electronic testing, and sensor calibration, success hinges on one thing: dimensional stability. Yet, even the most rigorous setups face a silent disruptor: electromagnetic interference (EMI). For engineers dealing with delicate sensors, magnetic components, or compliance testing, the base material of their inspection platform can be the difference between reliable data and corrupted results.

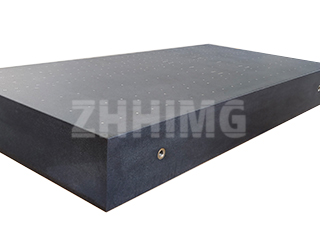

At ZHHIMG, we understand this critical link. Our Precision Granite Components are not just chosen for their flatness and stiffness; they are selected for their fundamental ability to resist magnetic interference, making them the superior choice over traditional materials like cast iron or steel.

The Non-Magnetic Advantage of Natural Granite

The effectiveness of granite as an anti-magnetic platform stems from its geological makeup. High-quality Black Granite is an igneous rock primarily composed of silicate minerals, such as quartz and feldspar, which are intrinsically non-magnetic and electrically non-conductive. This unique structure provides two definitive advantages in sensitive testing environments:

- Eliminating Ferromagnetic Interference: Unlike metal, which can be magnetized by external fields and introduce a magnetic ‘memory’ or influence to the test area, granite remains magnetically inert. It will not generate, store, or distort the magnetic field, ensuring that the only magnetic signature present is that of the components being measured.

- Stopping Eddy Currents: Metal is an electrical conductor. When a conductive material is exposed to a fluctuating magnetic field (a common occurrence in testing), it generates circulating electrical currents known as eddy currents. These currents create their own secondary magnetic fields, actively polluting the measurement environment. As an electrical insulator, granite simply cannot form these interfering currents, thus removing a major source of noise and instability.

Beyond Magnetic Purity: The Metrology Trifecta

While the non-magnetic trait is crucial, ZHHIMG’s granite metrology platforms offer a full suite of characteristics that reinforce measurement purity:

- Superior Vibration Damping: The dense, fine-grained structure of our granite naturally absorbs mechanical and acoustic vibrations, minimizing noise that could corrupt the readings of ultra-sensitive magnetic sensors.

- Thermal Stability: Granite exhibits an exceptionally low coefficient of thermal expansion. This means that unlike metal, which can warp or drift due to temperature changes (sometimes caused by eddy current heating), the granite’s reference plane maintains its geometry, guaranteeing dimensional stability and sub-micron repeatability.

- Corrosion-Proof Durability: Granite is naturally resistant to rust, corrosion, and common chemicals, ensuring the platform’s long-term integrity and accuracy without the degradation seen in cast iron bases.

Ideal Environments for ZHHIMG Granite

These properties make ZHHIMG’s precision granite the essential Ultra-Precision Platform for leading industries worldwide. We build the stable foundation for critical applications, including:

- Electromagnetic Compatibility (EMC) and EMI Testing

- Magnetic Sensor Calibration and Testing

- Coordinate Measuring Machines (CMMs)

- Semiconductor Wafer Inspection and Fabrication

- Optical Alignment and Laser Systems

When your testing or manufacturing requires a Vibration Damping Base that offers magnetic purity and unwavering stability, trust ZHHIMG’s expertise in Custom Granite Components to deliver the perfect solution.

Post time: Oct-14-2025