As industrial demands for measurement accuracy continue to escalate, Electromagnetic Interference (EMI) has become a critical factor threatening the stability of ultra-precision environments. ZHONGHUI Group (ZHHIMG®) today shares a technical insight, detailing the superior Anti-Magnetic Interference capabilities of its Precision Granite Inspection Tables and their indispensable role in complex electromagnetic testing scenarios.

1. Granite: A Natural Anti-Magnetic Shield

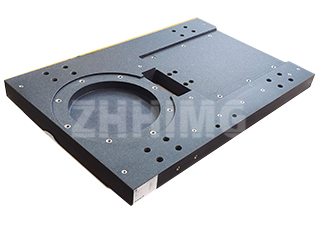

Unlike metal bases such as steel or cast iron, the fundamental advantage of ZHHIMG® Precision Granite is its inherent characteristic as a non-metallic, non-magnetic material.

- Fundamentally Non-Magnetic: Granite is primarily composed of silicate minerals like quartz, feldspar, and mica. These minerals are intrinsically non-magnetic, meaning they will not be magnetized by external magnetic fields nor will they generate induction or resonance in response to ambient electromagnetic waves.

- Elimination of Eddy Currents: Metal materials generate eddy currents in changing magnetic fields. These currents not only cause heating but also create secondary electromagnetic fields that severely interfere with delicate sensors and measurement results. As an insulator, granite completely eliminates the eddy current effect.

This non-magnetic property makes the ZHHIMG® Granite Inspection Table an ideal base for applications requiring extremely controlled electromagnetic environments, such as electronic component testing, magnetic sensor calibration, industrial CT/X-Ray equipment, and semiconductor inspection.

2. The ZHHIMG® Advantage: High Density Meets Ultra-Precision

While all granite is non-magnetic, ZHHIMG® Black Granite’s unique high density and advanced ultra-precision processing technology further enhance its superiority as a metrology base:

- High Density for Superior Stability: Our ZHHIMG® Black Granite boasts a density of approximately 3100 kg/m3, surpassing standard granite. High density translates to greater mass and inertia, which effectively isolates mechanical vibrations (which often couple with electromagnetic interference) during testing, ensuring the base’s physical stability.

- Non-Magnetic Insert Handling: For granite components requiring Thread Inserts, ZHHIMG® can customize the solution based on the client’s Electromagnetic Compatibility (EMC) requirements. We use non-magnetic stainless steel (e.g., high-grade austenitic steel) or non-conductive materials, precisely bonded with specialized epoxy resin to ensure the entire platform’s magnetic environment integrity.

3. Ideal Solution for Advanced Electromagnetic Testing

ZHHIMG®’s Precision Granite Inspection Tables offer irreplaceable value in the following high-tech sectors:

| Application Scenario | Core Requirement |

ZHHIMG® Value Proposition

|

| Semiconductor Equipment | Extremely low vibration & zero EMI |

High-density granite provides excellent damping; non-magnetic ensures pure testing results.

|

| Industrial CT / X-Ray | Long-term stability of the base position |

Low thermal expansion coefficient ensures equipment remains drift-free during long operations.

|

| CMM / Metrology Devices | Accuracy and resistance to interference |

Nanometer-level flatness combined with non-magnetic properties for the purest measurement environment.

|

4. Quality and Certification: Confidence for Global Clients

ZHHIMG® strictly adheres to its commitment to clients: “No cheating, No concealment, No misleading.” We operate under the philosophy that ultra-precision can never be too demanding. We are the ONLY company in the industry to simultaneously hold ISO 9001, ISO 45001, ISO 14001, and CE certifications, ensuring every step from material sourcing to final delivery meets the highest global standards.

ZHHIMG® welcomes global clients (including Oracle, Samsung, GE, and others) to collaborate with us on developing and customizing ultra-precision granite solutions for the most stringent electromagnetic testing environments.

Post time: Oct-09-2025