In the high-end manufacturing sector, ZHHIMG granite components stand out for their outstanding quality, which is attributed to their strict control over the entire process from mining to precision processing. In particular, the selection of high-quality natural black granite as the main material has laid a solid foundation for the standardization of the product.

I. Precise Mining: Quality Control at the source

ZHHIMG is well aware that high-quality raw materials are the foundation for achieving outstanding products. In the early stage of mining, a professional geological team uses advanced exploration techniques to conduct a comprehensive assessment of the mineral source and precisely identify the areas rich in high-quality natural black granite. The granite in these areas has advantages such as dense mineral crystallization, high hardness and few impurities, providing an inherent guarantee for subsequent processing and product performance.

During the mining process, advanced and environmentally friendly mining technologies, such as wire rope sawing, are adopted. This ensures the mining efficiency while minimizing damage to the stone materials to the greatest extent, guaranteeing that the mined blocks have high integrity and uniform texture. At the same time, strictly adhere to the concept of environmental protection, and properly dispose of the waste generated during the mining process to reduce the impact on the environment. The mined blocks will be promptly transported to professional storage areas and classified and stored according to quality grades, providing an orderly and high-quality raw material supply for subsequent processing.

Ii. Preliminary Processing: Laying the foundation for the initial form of standards

After the raw materials enter the processing plant, the first processes they encounter are rough machining and sawing. By using large-scale high-precision sawing equipment, large blocks of raw materials are cut into precisely sized rough boards in accordance with the design requirements. During this process, experienced technicians will closely monitor the sawing parameters to ensure that the cutting surface is smooth and flat, and the dimensional error is controlled within a very small range.

Then, edge grinding and initial surface treatment are carried out. The edges of the rough board are finely ground through professional edge grinding equipment to make them regular and smooth. Meanwhile, the surface of the stone is pre-treated by techniques such as sandblasting and grinding to remove the rough skin, laying a good foundation for subsequent fine processing.

Iii. Fine Processing: Forging Outstanding Standards

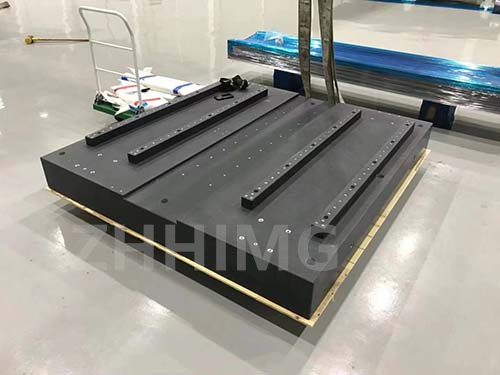

Entering the fine processing stage, ZHHIMG granite components begin to demonstrate their extraordinary quality. The cutting and forming processes employ advanced CNC cutting equipment. Based on precise design drawings, the rough plates are cut into components that meet various complex shape requirements. The high-precision positioning and cutting technology of the equipment ensures that the dimensional error of the components does not exceed ±0.1mm, meeting the strict requirements for dimensional accuracy in the high-end manufacturing field.

For components with special decorative or functional requirements, engraving and decoration treatments will be carried out. Experienced artisans or advanced CNC engraving machines can precisely engrave fine patterns, characters or functional structures on the surface of components, further enhancing the added value and practicality of the components.

Iv. Post-processing: Polishing perfect quality

The finely processed components will undergo polishing and surface finish treatment. Through multiple fine polishing processes and in combination with professional polishing materials, the surface of granite components achieves an extremely high degree of smoothness, with uniform and long-lasting luster. This not only enhances the aesthetic appeal of the components, but also improves their anti-fouling and wear-resistant performance.

Strict inspection and quality control run through the entire process. Professional quality inspection teams conduct comprehensive tests on the appearance defects, dimensional accuracy, flatness, physical properties and other aspects of components in accordance with international and industry high standards. No minor flaw can escape the "sharp eyes" of quality inspectors. Only products that fully meet the standards will be allowed to enter the packaging process.

V. Packaging and Transportation: Safety delivery Guarantee

The ZHHIMG granite components that have undergone multiple strict inspections will be carefully wrapped with professionally customized packaging materials. According to the shape, size and fragility of the components, buffer materials, protective frames, etc. are matched to ensure that the components are fully protected during transportation. Subsequently, in accordance with the requirements of the customer's order, select the appropriate transportation mode to deliver the goods to the destination in a timely and safe manner.

From mining to precision processing, ZHHIMG has always adhered to an unwavering pursuit of quality, selecting high-quality natural black granite and crafting each granite component with exquisite craftsmanship and strict standards, providing reliable and high-quality products for the global high-end manufacturing sector.

Post time: May-13-2025