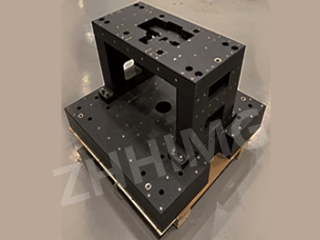

In the field of precision manufacturing, the quality of equipment bases is directly related to production accuracy and efficiency. ZHHIMG® has always adhered to its commitment to transparency, creating zero-defect hidden granite machine bases with strict standards, and providing customers with visible and reliable high-quality products through practical cases.

A globally renowned semiconductor enterprise, when developing a new generation of chip cutting equipment, has put forward extremely high requirements for the stability and precision of the base. They chose to collaborate with ZHHIMG® to purchase customized granite machine bases. ZHHIMG® controls quality from the source, carefully selecting high-quality natural granite veins. Each raw material undergoes strict screening and testing to ensure that the density meets the standard (approximately 3100kg/m³) and the internal structure is dense and uniform. During the production process, advanced processing techniques and high-precision equipment are adopted, along with an experienced technical team. Every procedure adheres to strict standards. Meanwhile, international leading detection technologies are introduced. Through methods such as ultrasonic flaw detection and laser flatness inspection, a comprehensive "physical examination" is conducted on the base, leaving no minor flaws unchecked. The final delivered base helped the enterprise improve the chip cutting accuracy to ±0.5μm, increasing the yield rate by 12%, far exceeding the industry average.

Another enterprise specializing in the manufacturing of optical instruments has frequently encountered problems with the optical axis deviation of its products due to defects in the base. The situation has been greatly improved after switching to the ZHHIMG® granite machine base. ZHHIMG® proactively discloses its production process, inspection data and quality reports to customers, allowing them to clearly understand every detail of the products. With its outstanding quality of zero hidden defects, the new base effectively supholds the interference of vibration on the optical system, improving the measurement accuracy of the instrument by 30%. It has successfully helped the enterprise win multiple high-end orders and consolidated its market position.

The triple authoritative certifications (ISO 9001, ISO 14001, ISO 45001) are even more powerful proof of the transparency of ZHHIMG®. Whether it is high-precision equipment for semiconductor manufacturing or demanding optical instruments, the granite machine base of ZHHIMG® always ensures the stable operation of the equipment with its genuine and reliable quality, allowing customers to choose with confidence and use with peace of mind.

Post time: Jun-10-2025