One of Hottest for Granite Straight Edge - Mineral Casting Machine Bed – ZHONGHUI

One of Hottest for Granite Straight Edge - Mineral Casting Machine Bed – ZHONGHUI Detail:

Customer benefits

The primary customer benefit of our mineral casting is the variety of applications for machines of all conceivable sizes. Mineral casting is not only less expensive than gray cast iron, for instance, but also demonstrates five to ten times better vibration behavior and high chemical resistance. Furthermore, because the polymer concrete (pure black granite Gravel with synthetic resin as a binding agent) is only cast at approximately 60 °C connecting parts, pipes and cables, as well as sensor systems and measuring technology can also be cast into the structures.

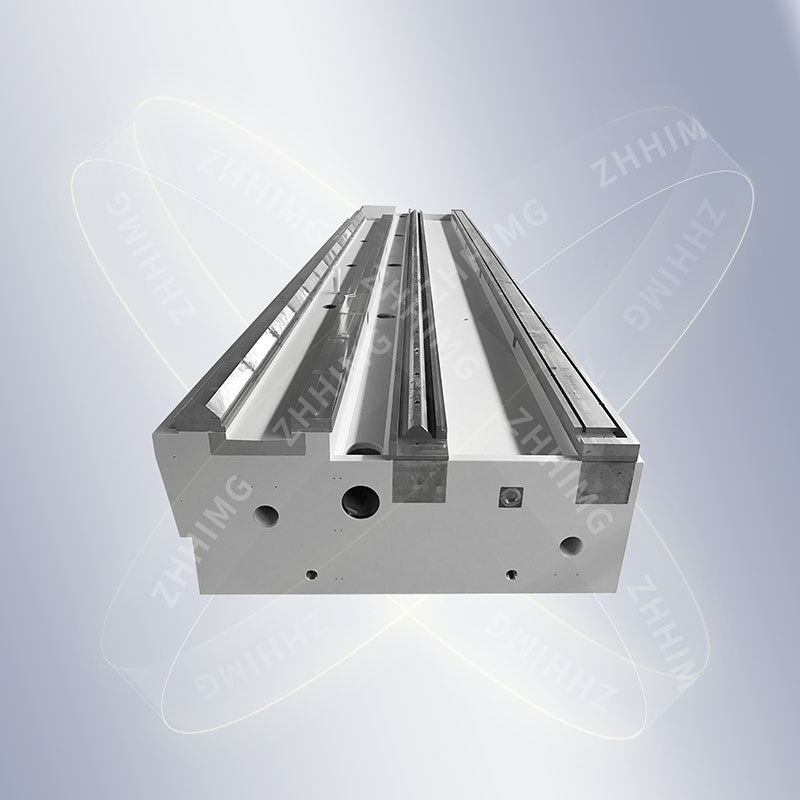

Example of a machine bed

A look at the shape of a machine bed for an electrical discharge system prior to casting shows some of the above-mentioned benefits of mineral casting. You can see plastic pipes that are firmly cast into the machine bed. They are used later in the finished system for various supply lines. Various threaded inserts can also be seen, which later serve as interfaces to other machine components. After shaping, all that’s left to do on the finished casting is to finish the precise connecting surfaces. All of this results in considerably less effort – and lower costs – in comparison to a machine bed made of steel or cast iron materials. And last but not least, mineral casting is an ecologically sustainable material that is virtually 100 % reusable.

Combined with linear motion technology

It goes without saying that our mineral casting and linear motion technology can be optimally combined. Especially because mineral casting has thermal expansion properties that are similar to steel.

Extensive range of applications

However, with its typical characteristics and benefits, mineral casting is by no means only suitable for machine tool construction. Customers in many other sectors also acknowledge and take advantage of the benefits of this material, which opens up an extensive range of applications for them. This means that our mineral casting is also used with a high level of success in medical technology, the solar, electronics and packaging industries, to name just a few examples.

|

Model |

Details |

Model |

Details |

|

Size |

Custom |

Application |

CNC, Laser, CMM… |

|

Condition |

New |

After-sales Service |

Online supports, Onsite supports |

|

Origin |

Jinan City |

Material |

Metal Casting |

|

Color |

Metal Original Color |

Brand |

ZHHIMG |

|

Precision |

0.001mm |

Weight |

≈7g/cm3 |

|

Standard |

DIN/ GB/ JIS… |

Warranty |

1year |

|

Packing |

Export Plywood CASE |

After Warranty Service |

Video technical support, Online support, Spare parts, … |

|

Payment |

T/T, L/C… |

Certificates |

Inspection Reports/ Quality Certificate |

|

Keyword |

Ceramic Machine Base; Ceramic Mechanical Components; Ceramic Machine Parts; Precision Ceramic |

Certification |

CE, GS, ISO, SGS, TUV… |

|

Delivery |

EXW; FOB; CIF; CFR; DDU; CPT… |

Drawings’ format |

CAD; STEP; PDF… |

● Virbration Damping

The vibration and engineering data of Nano’s artificial stone show: 1.5in. X1.5in. X9in. Bar pressure casting material samples were tested for vibration damping at 70 degrees Fahrenheit. The results are shown in the figure: Nano-man-made stone has a vibration-reducing ability 45 times faster than alumina, 10 times faster than cast iron and steel, and 4 times faster than granite.

● High precision

● Flexible design

● Cut costs

● Heat resistance

The lower coefficient of heat expansion compared with the metal

Minimizes thermal gradients

● Green

Environment-friendly

● Save Time

Reduce steps and time during equipment installation and commissioning

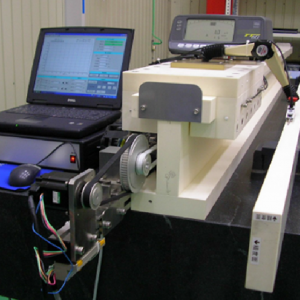

We use various techniques during this process:

● Optical measurements with autocollimators

● Laser interferometers and laser trackers

● Electronic inclination levels (precision spirit levels)

1. Documents together with products: Inspection reports + Calibration reports(measuring devices) + Quality Certificate + Invoice + Packing List + Contract + Bill of Lading(or AWB).

2. Special Export Plywood Case: Export fumigation-free wooden box.

3. Delivery:

|

Ship |

Qingdao port |

Shenzhen port |

TianJin port |

Shanghai port |

… |

|

Train |

XiAn Station |

Zhengzhou Station |

Qingdao |

… |

|

|

Air |

Qingdao Airport |

Beijing Airport |

Shanghai Airport |

Guangzhou |

… |

|

Express |

DHL |

TNT |

Fedex |

UPS |

… |

1. We will offer technical supports for assembly, adjustment, maintain.

2. Offering the manufacturing &inspection videos from selecting material to delivery, and customers can control and know every detail at anytime anywhere.

Product detail pictures:

Related Product Guide:

With a positive and progressive attitude to customer's curiosity, our organization repeatedly improves our products top quality to meet the wants of consumers and further focuses on safety, reliability, environmental necessities, and innovation of One of Hottest for Granite Straight Edge - Mineral Casting Machine Bed – ZHONGHUI , The product will supply to all over the world, such as: Berlin, Pakistan, Israel, We supply professional service, prompt reply, timely delivery, excellent quality and best price to our customers. Satisfaction and good credit to every customer is our priority. We focus on every detail of order processing for customers till they have received safe and sound products with good logistics service and economical cost. Depending on this, our products are sold very well in the countries in Africa, the Mid-East and Southeast Asia. Adhering to the business philosophy of ‘customer first, forge ahead', we sincerely welcome clients from at home and abroad to cooperate with us.

QUALITY CONTROL

If you can’t measure something, you can’t understand it!

If you can’t understand it.you cant control it!

If you can’t control it, you can’t improve it!

More information please click here: ZHONGHUI QC

ZhongHui IM, your partner of metrology, help you succeed easily.

Our Certificates & Patents:

Certificates and Patents are an expression of a company’s strength. It’s society’s recognition of the company.

More certificates please click here: Innovation & Technologies – ZHONGHUI INTELLIGENT MANUFACTURING (JINAN) GROUP CO., LTD (zhhimg.com)

Material Analysis (Physical Properties):

1. Granite Material from Mines

1. Granite Material from Mines

2. Ceramic Material

3. Mineral Casting

4. Precision Metal

5. Precision Glass

6. UHPC

7. Carbon fiber

The quality of the products is very good, especially in the details, can be seen that the company work actively to satisfy customer's interest, a nice supplier.