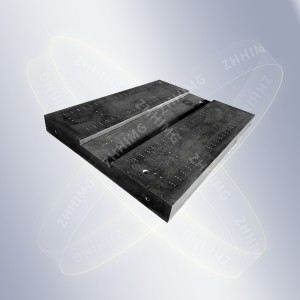

ZHHIMG® Precision Granite Assembly

What you see is not just stone; it is ZHHIMG® Black Granite, a material carefully selected for its exceptional physical properties. With a density of approximately 3100kg/m³, this granite offers a level of mass and structural integrity that far exceeds standard marble or architectural stone. For engineers in the USA and Europe, this translates to an unshakable foundation with a near-zero coefficient of thermal expansion. This ensures that whether you are integrating a linear motor platform or a high-speed AOI system, your datum remains stable regardless of minor ambient temperature fluctuations.

Product Details and Engineering Excellence

This assembly is engineered to be the "chassis" of a high-precision machine. Key features include:

• Integrated T-Slots and Inserts: Precision-machined slots and threaded inserts are integrated directly into the granite, allowing for the direct mounting of high-precision guide rails and drive systems without compromising the stone's flatness.

• Ultra-Precision Flatness (Grade 00): Every mounting surface is hand-lapped by our master craftsmen—our "walking electronic levels"—to meet or exceed DIN 876, JIS, and ASME standards.

• Vibration Damping: The natural gabbro-diabase structure of our black granite absorbs the micro-vibrations generated by high-speed motion, ensuring that your sensors can capture data without "noise."

• Custom Geometric Tolerances: The perpendicularity between the vertical gantry and the horizontal base is achieved through meticulous hand-lapping, ensuring that the XY-Z relationship is mechanically perfect before you even turn on your software compensation.

|

Model |

Details |

Model |

Details |

|

Size |

Custom |

Application |

CNC, Laser, CMM... |

|

Condition |

New |

After-sales Service |

Online supports, Onsite supports |

|

Origin |

Jinan City |

Material |

Black Granite |

|

Color |

Black / Grade 1 |

Brand |

ZHHIMG |

|

Precision |

0.001mm |

Weight |

≈3.05g/cm3 |

|

Standard |

DIN/ GB/ JIS... |

Warranty |

1year |

|

Packing |

Export Plywood CASE |

After Warranty Service |

Video technical support, Online support, Spare parts, Field mai |

|

Payment |

T/T, L/C... |

Certificates |

Inspection Reports/ Quality Certificate |

|

Keyword |

Granite Machine Base; Granite Mechanical Components; Granite Machine Parts; Precision Granite |

Certification |

CE, GS, ISO, SGS, TUV... |

|

Delivery |

EXW; FOB; CIF; CFR; DDU; CPT... |

Drawings’ format |

CAD; STEP; PDF... |

The versatility of the ZHHIMG® Granite Assembly makes it an essential component for:

• Semiconductor Fabrication: Serving as the stable base for wafer inspection and lithography equipment.

• PCB Industry: Providing the rigid frame for high-speed drilling & milling machines.

• Metrology & CMM: Acting as the primary reference for 3D coordinate measuring machines.

• Optical & Laser Processing: Supporting femtosecond and picosecond laser systems where any vibration would result in catastrophic errors.

We use various techniques during this process:

● Optical measurements with autocollimators

● Laser interferometers and laser trackers

● Electronic inclination levels (precision spirit levels)

1. Documents together with products: Inspection reports + Calibration reports(measuring devices) + Quality Certificate + Invoice + Packing List + Contract + Bill of Lading(or AWB).

2. Special Export Plywood Case: Export fumigation-free wooden box.

3. Delivery:

|

Ship |

Qingdao port |

Shenzhen port |

TianJin port |

Shanghai port |

... |

|

Train |

XiAn Station |

Zhengzhou Station |

Qingdao |

... |

|

|

Air |

Qingdao Airport |

Beijing Airport |

Shanghai Airport |

Guangzhou |

... |

|

Express |

DHL |

TNT |

Fedex |

UPS |

... |

To ensure your precision granite inspection table and assembly maintain their Grade 00 accuracy for decades, follow these professional maintenance protocols:

1.Environment Control: Keep the assembly in a constant temperature and humidity environment. Our own facility utilizes a 10,000m² cleanroom to ensure that "precision business is never too demanding."

2.Cleaning: Use only professional granite cleaners. Avoid water or household chemicals that can leave a residue. Wipe the surface before every use to remove microscopic dust that can act as an abrasive.

3.Load Management: Never leave heavy parts on the assembly for extended periods when not in use, as this can lead to subtle, long-term deformation.

4.Regular Calibration: Schedule a surface plate calibration procedure annually using traceable equipment like Renishaw laser interferometers or Wyler electronic levels to ensure the integrity of your reference plane.

QUALITY CONTROL

If you can’t measure something, you can’t understand it!

If you can’t understand it.you cant control it!

If you can’t control it, you can’t improve it!

More information please click here: ZHONGHUI QC

ZhongHui IM, your partner of metrology, help you succeed easily.

Our Certificates & Patents:

ISO 9001, ISO45001, ISO14001, CE, AAA Integrity Certificate, AAA-level enterprise credit certificate…

Certificates and Patents are an expression of a company’s strength. It’s society’s recognition of the company.

More certificates please click here: Innovation & Technologies – ZHONGHUI INTELLIGENT MANUFACTURING (JINAN) GROUP CO., LTD (zhhimg.com)