ZHHIMG® Precision Granite Components and Bases

The superior performance of this granite base starts with the material itself. We exclusively utilize our proprietary ZHHIMG® Black Granite (a high-density gabbro), specifically selected for its exceptional physical properties that surpass common gray granite and unstable marble alternatives:

● Extreme Density: Our material boasts a high density of approximately 3100 kg/m³. This superior mass contributes directly to greater stiffness (Young's modulus), which is critical for minimizing deflection under load and maintaining the integrity of the reference plane.

● Superior Stability: The granite is naturally stress-relieved over millennia. We further enhance this by controlled aging processes, ensuring that the finished component exhibits minimal internal stress and virtually no susceptibility to warping or dimensional creep over time.

● Optimal Thermal Performance: Granite possesses extremely low thermal conductivity and a minimal coefficient of thermal expansion. This ensures that the base maintains dimensional stability even under slight ambient temperature fluctuations, a non-negotiable requirement for sub-micron accuracy.

● Durability and Cleanliness: Unlike metal structures, granite is non-magnetic, corrosion-free, and requires no protective plating, making it ideal for cleanroom environments and long-term use without degradation.

|

Model |

Details |

Model |

Details |

|

Size |

Custom |

Application |

CNC, Laser, CMM... |

|

Condition |

New |

After-sales Service |

Online supports, Onsite supports |

|

Origin |

Jinan City |

Material |

Black Granite |

|

Color |

Black / Grade 1 |

Brand |

ZHHIMG |

|

Precision |

0.001mm |

Weight |

≈3.05g/cm3 |

|

Standard |

DIN/ GB/ JIS... |

Warranty |

1year |

|

Packing |

Export Plywood CASE |

After Warranty Service |

Video technical support, Online support, Spare parts, Field mai |

|

Payment |

T/T, L/C... |

Certificates |

Inspection Reports/ Quality Certificate |

|

Keyword |

Granite Machine Base; Granite Mechanical Components; Granite Machine Parts; Precision Granite |

Certification |

CE, GS, ISO, SGS, TUV... |

|

Delivery |

EXW; FOB; CIF; CFR; DDU; CPT... |

Drawings’ format |

CAD; STEP; PDF... |

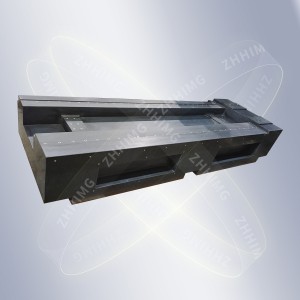

This customized component is a testament to our ability to combine natural material superiority with advanced engineering and machining capabilities. The base is precision-machined to serve multiple critical functions:

● Flatness and Geometry: The primary working surfaces are lapped to achieve ultra-high flatness tolerances, often to the nanometer level. This is achieved through a combination of ultra-large Taiwanese grinding equipment and final hand-lapping by our master craftsmen, many of whom have over 30 years of experience and are capable of sub-micron material removal.

● Custom Integration Points: The component features precisely machined T-slots, threaded inserts, and dowel pin holes. These are permanently bonded into the granite structure with specialized epoxy, allowing for direct, high-accuracy mounting of linear motors, lead screws, guide rails, and specialized fixtures. * Internal Structural Design: The base is engineered with internal stiffening ribs and cutouts to optimize the stiffness-to-weight ratio while simplifying the structure for stress-free mounting.

● Vibration Isolation: The mass and structure of the granite inherently provide superior vibration damping compared to cast iron or steel, effectively isolating the sensitive moving parts of the machine from environmental disturbances.

We use various techniques during this process:

● Optical measurements with autocollimators

● Laser interferometers and laser trackers

● Electronic inclination levels (precision spirit levels)

1. Documents together with products: Inspection reports + Calibration reports(measuring devices) + Quality Certificate + Invoice + Packing List + Contract + Bill of Lading(or AWB).

2. Special Export Plywood Case: Export fumigation-free wooden box.

3. Delivery:

|

Ship |

Qingdao port |

Shenzhen port |

TianJin port |

Shanghai port |

... |

|

Train |

XiAn Station |

Zhengzhou Station |

Qingdao |

... |

|

|

Air |

Qingdao Airport |

Beijing Airport |

Shanghai Airport |

Guangzhou |

... |

|

Express |

DHL |

TNT |

Fedex |

UPS |

... |

Maintaining the superior performance of your Precision Granite Base is straightforward due to the material's inherent properties:

● Cleaning: Use only a mild, non-abrasive granite cleaner or denatured alcohol. Never use solvents or abrasive pads that could damage the finely lapped surface.

● Calibration: While granite is extremely stable, professional recalibration should be scheduled annually (or according to your quality system) using laser interferometers and electronic levels to ensure continued adherence to DIN, ASME, or JIS standards.

● Handling: Always lift the component with appropriate equipment, ensuring the load is distributed evenly to avoid localized stress.

We stand by the quality of every component we manufacture. As the industry's only producer simultaneously certified to ISO 9001, ISO 45001, ISO 14001, and CE standards, ZHHIMG® guarantees a product of uncompromised quality, backed by a global commitment to metrological precision.

QUALITY CONTROL

If you can’t measure something, you can’t understand it!

If you can’t understand it.you cant control it!

If you can’t control it, you can’t improve it!

More information please click here: ZHONGHUI QC

ZhongHui IM, your partner of metrology, help you succeed easily.

Our Certificates & Patents:

ISO 9001, ISO45001, ISO14001, CE, AAA Integrity Certificate, AAA-level enterprise credit certificate…

Certificates and Patents are an expression of a company’s strength. It’s society’s recognition of the company.

More certificates please click here: Innovation & Technologies – ZHONGHUI INTELLIGENT MANUFACTURING (JINAN) GROUP CO., LTD (zhhimg.com)