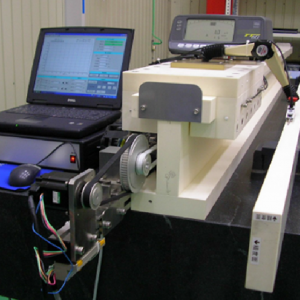

Granite Base for Precision Engraving Machines

Precision granite machine bases are widely used in many industries due to their unique properties. These bases are made from high-quality granite, which provides exceptional stability, rigidity, and precision. The following are the key areas where precision granite machine bases are used:

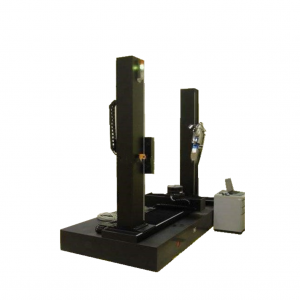

1. Metrology: In the metrology field, precision granite machine bases are used as reference standards for measuring various industrial parts and components. They provide high accuracy and repeatability, which is essential in this field.

2. Aerospace: In the aerospace industry, precision granite machine bases are used in the manufacturing and assembly of critical components that require extreme accuracy and stability. These bases are used in the production of airplane wings, engine parts, and other critical components.

3. Electronics: In the electronics industry, precision granite machine bases are used for manufacturing and testing electronic parts and components. These bases provide a stable and rigid platform, which is essential in the production of high-quality electronic parts.

4. Automotive: In the automotive industry, precision granite machine bases are used for manufacturing and testing critical parts such as engines, transmissions, and suspension systems. These bases provide high precision and stability, which are necessary for producing high-quality automotive parts.

5. Medical: In the medical industry, precision granite machine bases are used for the manufacturing of precision medical devices such as prosthetics, implants, and surgical instruments. These bases provide high accuracy and repeatability, which are essential in this field.

The main advantages of using precision granite machine bases are as follows:

1. Stability: The use of granite provides exceptional stability, which is essential in industries where precision is critical.

2. Precision: These bases provide high accuracy and repeatability, making them essential in industries where precision is paramount.

3. Durability: Granite is a durable material that can withstand harsh environments and vibrations without affecting its performance.

4. High Load Capacity: Granite machine bases have a high load capacity, which allows them to support heavy loads without any deformation.

5. Low Thermal Expansion: Granite has low thermal expansion properties, which means that it is not affected by temperature changes. This ensures high accuracy and repeatability in different environments.

In conclusion, precision granite machine bases are essential in many industries where precision and stability are critical. These bases offer high accuracy, repeatability, durability, and load capacity, making them a popular choice for many applications. With their unique properties, precision granite machine bases are expected to continue playing a vital role in various industries in the coming years.

|

Model |

Details |

Model |

Details |

|

Size |

Custom |

Application |

CNC, Laser, CMM... |

|

Condition |

New |

After-sales Service |

Online supports, Onsite supports |

|

Origin |

Jinan City |

Material |

Black Granite |

|

Color |

Black / Grade 1 |

Brand |

ZHHIMG |

|

Precision |

high than 0.001mm |

Weight |

≈3.1g/cm3 |

|

Standard |

DIN/ GB/ JIS... |

Warranty |

1year |

|

Packing |

Export Plywood CASE |

After Warranty Service |

Video technical support, Online support, Spare parts, Field mai |

|

Payment |

T/T, L/C... |

Certificates |

Inspection Reports/ Quality Certificate |

|

Keyword |

Granite Machine Base; Granite Mechanical Components; Granite Machine Parts; Precision Granite |

Certification |

CE, GS, ISO, SGS, TUV... |

|

Delivery |

EXW; FOB; CIF; CFR; DDU; CPT... |

Drawings’ format |

CAD; STEP; PDF... |

Precision granite machine bases are renowned for their exceptional quality and precision. Made from solid, natural granite, these machine bases offer superior accuracy, stability, and durability compared to other materials.

One of the key benefits of precision granite machine bases is their ability to absorb vibration. This is due to the unique properties of granite, which makes it an ideal material for machinery that requires high levels of precision and stability. The rigidity of the granite base ensures that machines operate smoothly, without any unwanted movement or vibration that could negatively impact their performance.

In addition, precision granite machine bases also exhibit remarkable thermal stability. Compared to other materials, granite has a low coefficient of thermal expansion, meaning it does not expand or contract significantly with temperature changes. This allows for consistent and reliable machine performance, even in fluctuating temperatures or extreme environments.

Another feature of precision granite machine bases is their ease of maintenance. Granite is a durable and non-porous material, making it resistant to corrosion, staining, and wear. As a result, these machine bases require minimal upkeep, saving time and effort for busy manufacturing operations.

Overall, precision granite machine bases are an excellent choice for those seeking reliable, accurate, and durable machinery. With their superior vibration absorption, thermal stability, and low maintenance requirements, they are an investment that pays off in performance and longevity.

We use various techniques during this process:

● Optical measurements with autocollimators

● Laser interferometers and laser trackers

● Electronic inclination levels (precision spirit levels)

1. Documents together with products: Inspection reports + Calibration reports(measuring devices) + Quality Certificate + Invoice + Packing List + Contract + Bill of Lading(or AWB).

2. Special Export Plywood Case: Export fumigation-free wooden box.

3. Delivery:

|

Ship |

Qingdao port |

Shenzhen port |

TianJin port |

Shanghai port |

... |

|

Train |

XiAn Station |

Zhengzhou Station |

Qingdao |

... |

|

|

Air |

Qingdao Airport |

Beijing Airport |

Shanghai Airport |

Guangzhou |

... |

|

Express |

DHL |

TNT |

Fedex |

UPS |

... |

1. We will offer technical supports for assembly, adjustment, maintain.

2. Offering the manufacturing &inspection videos from selecting material to delivery, and customers can control and know every detail at anytime anywhere.

QUALITY CONTROL

If you can’t measure something, you can’t understand it!

If you can’t understand it.you cant control it!

If you can’t control it, you can’t improve it!

More information please click here: ZHONGHUI QC

ZhongHui IM, your partner of metrology, help you succeed easily.

Our Certificates & Patents:

Certificates and Patents are an expression of a company’s strength. It’s society’s recognition of the company.

More certificates please click here: Innovation & Technologies – ZHONGHUI INTELLIGENT MANUFACTURING (JINAN) GROUP CO., LTD (zhhimg.com)

Material Analysis (Physical Properties):

1. Granite Material from Mines

1. Granite Material from Mines

2. Ceramic Material

3. Mineral Casting

4. Precision Metal

5. Precision Glass

6. UHPC

7. Carbon fiber