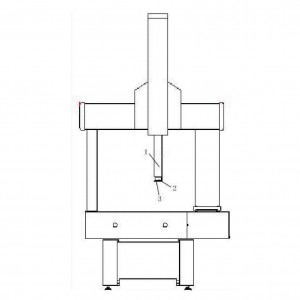

Why do high-end CMMs use industrial ceramics as the spindle beam and Z axis

☛Temperature stability: "Coefficient of Thermal Expansion" The thermal expansion coefficient of granite and industrial ceramics is only about 1/4 of that of aluminum alloy materials and 1/2 of that of steel.

☛Thermal compatibility: At present, the equipment of aluminum alloy (beam and main shaft), the workbench is mostly made of granite;

☛Anti-aging stability: After the aluminum alloy material is formed, there is a large internal stress in the component,

☛"Rigidity/mass ratio" parameter: industrial ceramics is 4 times that of aluminum alloy materials. That is: when the rigidity is the same, the industrial ceramic only needs 1/4 of the weight;

☛Corrosion resistance: non-metallic materials do not rust at all, and the inner and outer materials are the same (non-plated), which is easy to maintain.

Obviously, compared with industrial ceramics, the good dynamic performance of aluminum alloy material equipment is obtained by "sacrificing" rigidity.

In addition to the above reasons, forming methods such as aluminum alloy extrusion are lower than non-metallic materials in terms of forming accuracy.

Post time: Nov-11-2021