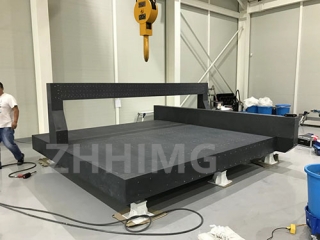

Granite assembly is a popular choice for image processing apparatus due to its durability and stability. Granite is a natural stone and is known for its hardness and high abrasion resistance, making it ideal for harsh environments such as image processing labs and manufacturing facilities. In this article, we will discuss the advantages and disadvantages of granite assembly for image processing apparatus.

Advantages of Granite Assembly:

1. Stability: One of the main advantages of granite assembly is its stability. Granite is a dense material and does not expand or contract easily in response to temperature changes, vibrations, or other environmental factors. This makes it an ideal material for image processing apparatus that require stable and accurate positioning of components.

2. Durability: Granite is an incredibly durable material. It can withstand heavy use and is resistant to scratches, corrosion, and other forms of wear and tear. This means that image processing apparatus made with granite assembly can last for decades without requiring any significant repairs or replacements.

3. Precision: Granite is a high-precision material that is often used in applications where accuracy is critical. For image processing apparatus, this means that components can be aligned with extreme precision, allowing for accurate and repeatable measurements.

4. Low Maintenance: Because granite is so durable and resistant to wear and tear, image processing apparatus made with granite assembly require minimal maintenance. This means that operators can focus on their work without worrying about frequent and expensive repair and maintenance costs.

Disadvantages of Granite Assembly:

1. Expense: Granite assembly can be more expensive than other materials, such as aluminum or steel. However, the long-term durability and stability of granite may outweigh this additional cost in the long run.

2. Weight: Granite is a dense and heavy material, which can make it difficult to move or transport large image processing apparatus made with granite assembly. However, this weight also contributes to its stability.

3. Difficult to Modify: Because granite is such a hard and durable material, it can be difficult to modify or repair once it has been assembled into an image processing apparatus. This means that any changes or modifications may require significant time and resources.

4. Impact Sensitivity: While granite is incredibly hard and durable, it is also slightly more sensitive to impact than some other materials. This means that operators need to be careful when handling delicate components to avoid damaging the granite assembly.

In conclusion, granite assembly has many advantages for image processing apparatus, including stability, durability, precision, and low maintenance. While it may be more expensive than some other materials, its long-term durability and stability may make it a better choice for many applications. Indeed, the disadvantages associated with granite assembly, such as weight and impact sensitivity, are far outweighed by its many benefits. Therefore, image processing operators that seek a long-term solution should consider granite as a great material choice for their image processing apparatus.

Post time: Nov-24-2023