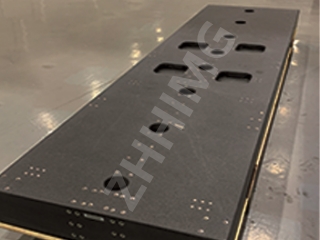

Granite bases are an integral component of industrial computed tomography (CT) machines. They provide stability, rigidity, and accuracy for the machine, which are crucial for obtaining precise and reliable results. However, due to wear and tear and mishandling, the granite base can get damaged, which affects the performance of the machine. It is essential to repair the appearance of the damaged granite base and recalibrate the accuracy for optimal performance.

Here is a step-by-step guide on how to repair the appearance of the damaged granite base and recalibrate the accuracy:

Step 1: Inspect the damage

Before proceeding with any repair work, it is crucial to inspect the extent of the damage. Look for any cracks, chips, scratches, or other visible signs of damage on the granite base. Make a note of the damage and assess the impact it may have on the performance of the machine.

Step 2: Clean the surface

Use a soft cloth and a mild cleaning solution to clean the surface of the granite base. Be gentle and avoid using abrasive cleaners as they may further damage the surface of the granite. Rinse the surface thoroughly and let it dry completely.

Step 3: Repair the damage

Depending on the extent of the damage, there are several ways to repair the granite base. For minor scratches and chips, you can use a granite repair kit to fill in the damaged areas. For more significant damage, you may need to call in a professional to repair the damage or even replace the granite base altogether.

Step 4: Recalibrate the accuracy

After repairing the damage, it is essential to recalibrate the accuracy of the CT machine. This process involves aligning the different components of the machine to ensure they are working together correctly and providing accurate results. This process is typically performed by the manufacturer or a certified technician.

Step 5: Regular maintenance

To prevent further damage to the granite base and ensure optimal performance of the CT machine, it is essential to perform regular maintenance. This includes cleaning the surface regularly, avoiding mishandling and impacts, and staying up to date with any necessary upgrades or repairs.

In conclusion, repairing the appearance of the damaged granite base for industrial CT machines and recalibrating the accuracy is essential for optimal performance and reliable results. By following the above steps and taking proactive measures to maintain the machine properly, you can ensure that your CT machine operates at its best for years to come.

Post time: Dec-08-2023