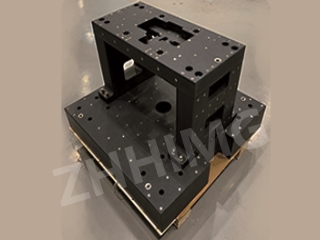

Granite is a highly durable and reliable material that is used in a wide range of applications. It is often used as a base for heavy machinery and equipment due to its resistance to wear and tear and its ability to maintain its shape and accuracy over time. However, even the most durable materials can become damaged over time, especially in high-use environments. When granite machine components become damaged, it is essential to repair the appearance and recalibrate the accuracy to ensure the performance of the equipment is not compromised. In this article, we will look at the steps you can take to repair the appearance of the damaged granite machine components and recalibrate the accuracy.

Step 1: Identify the Damage

The first step in repairing granite machine components is to identify the damage. Look closely at the granite surface and identify any cracks or chips. If the damage is severe, it may require the expertise of a professional. However, if it is a minor chip or scratch, you should be able to repair it yourself.

Step 2: Clean the Surface

Before repairing any damage, it is important to clean the surface of the granite. Use a soft cloth or brush to remove any dust or debris. If the surface is particularly dirty, use a mild cleaner and water solution to clean it thoroughly. Be sure to rinse the surface with clean water and dry it thoroughly before proceeding.

Step 3: Repair the Damage

To repair small chips or scratches, use a granite repair kit. These kits contain epoxy or polyester resin, which can be colored to match the granite. Follow the instructions carefully and apply the resin to the damaged area. Use a putty knife to smooth the surface of the repair and remove any excess. Allow the resin to dry according to the manufacturer's instructions.

For larger damage or cracks that require professional work, you will need to contact a professional granite repair company.

Step 4: Recalibrate the Accuracy

Once the damage is repaired, it is important to recalibrate the accuracy of the granite machine components. Use a precision level to check if the base is level. Adjust the leveling feet on the machinery until the base is completely level. Use a granite reference plate to check the accuracy of the machinery. Place the reference plate on the granite surface and use a gauge block to check the accuracy. Calibrate the machinery until it is within the required specifications.

Conclusion

Granite machine components are an essential part of any heavy machinery or equipment. It is important to maintain them properly. Repairing the appearance of damaged granite components and recalibrating the accuracy ensures that the machinery runs smoothly and efficiently. With the right tools and techniques, repairing damaged granite components can be easy and effective. So, be proactive in the maintenance of your equipment, and it will pay off in the long run.

Post time: Oct-13-2023