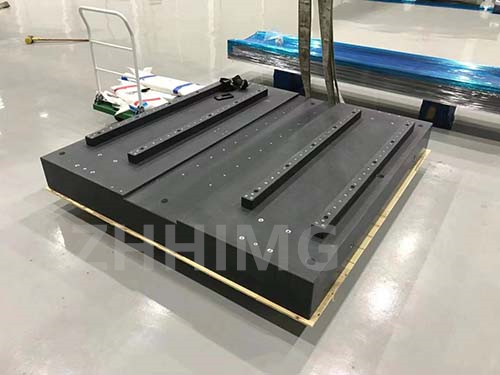

Granite XY tables, also known as precision granite surface plates, are important tools for precise measurement in the manufacturing, engineering and scientific industries. However, like any other mechanical component or tool, they are susceptible to damage, which can affect their accuracy and appearance. Fortunately, there are ways to repair the appearance of a damaged granite XY table and recalibrate its accuracy, as discussed in this article.

Repairing the Appearance of a Damaged Granite XY Table

The first step to repairing the appearance of a damaged granite XY table is to assess the extent of the damage. Some common forms of damage include scratches, nicks, chips, and stains. Once you have identified the type and extent of the damage, you can take appropriate steps to repair it.

1. Scratches: If the granite surface has minor scratches, you can try using a fine-grit sandpaper or a specialized granite polishing compound to buff out the scratches. Work in a circular motion and keep the surface wet with water to prevent the sandpaper or polishing compound from getting clogged.

2. Nicks and Chips: For deeper nicks and chips, you'll need to use an epoxy resin compound specifically made for granite repair. This compound helps to fill the damaged area, and once it dries, you can use sandpaper to smooth it out. It is essential to ensure the epoxy dries properly to avoid any damage.

3. Stains: Stains on granite surfaces can be a real eyesore. These stains are often caused by acids or other corrosive chemicals. If you encounter a stain, you can use a granite stain remover to remove the stain by following the manufacturer's instructions.

Recalibrating the Accuracy of a Granite XY Table

Once you've dealt with the repair of the appearance of a granite XY table, you're ready to tackle the task of recalibrating its accuracy. The calibration process is essential as it ensures that the table continues to offer accurate and consistent measurements.

Here are some tips to help you recalibrate your granite XY table:

1. Leveling: Leveling is essential for a granite XY table, and it can be achieved by using precision leveling tools. You can use a spirit level or a digital level to ensure a level workspace.

2. Cleanliness: Keeping the granite surface clean is vital, as any dust or dirt can affect the precision of the measurements. To clean the surface, you can use an alcohol-based cleaner, and once it is dry, you can use a blower to remove any dust.

3. Calibration Tools: You will require some precision calibration tools to ensure that your granite XY table is accurate. These tools typically include a height gauge, a dial indicator, and a surface plate prism. With these tools, you can check that your table is level, flat, parallel, and perpendicular.

4. Calibration Check: Once you've completed the recalibrating process, you can check your table's calibration using a dial indicator or a height gauge. It is vital to do this check regularly to ensure that the table continues to offer accurate and precise measurements.

Conclusion

Granite XY tables are essential tools, and their accuracy is vital to many industries. With these essential tips on repairing the appearance and recalibrating the accuracy of a granite XY table, you can ensure that it continues to provide accurate and reliable measurements while looking its best. Remember that proactive maintenance and regular checks are crucial to keeping your granite XY table in perfect condition.

Post time: Nov-08-2023