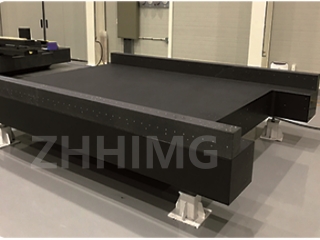

Precision granite is widely used in various industries such as mechanical engineering, metrology, and optical industries. This material is known for its excellent stability, durability, and accuracy. However, over time, precision granite can become damaged due to wear and tear, accidental impacts, or exposure to extreme temperatures. This can compromise its accuracy and affect its appearance.

If you are facing this problem, don't worry. In this article, we will guide you through the steps to repair the appearance of damaged precision granite, and recalibrate its accuracy. It is important to note that these steps need to be carried out by a skilled professional with the right tools and equipment.

Repairing the appearance of damaged Precision Granite:

Step 1: Cleaning the Surface: The first step in repairing the appearance of precision granite is to clean the surface. Use a soft cloth and a non-abrasive cleaner to remove any dirt, dust, or debris. If the surface is greasy, use a degreaser and rinse with water.

Step 2: Inspecting the Surface: Inspect the surface to identify the extent and type of damage. Some types of damage can be fixed with simple polishing, while others require more advanced techniques.

Step 3: Polishing the Surface: Minor scratches can be polished out using a polishing compound and a soft cloth. Make sure to use a compound that is suitable for precision granite surfaces. The polishing compound should be applied in a circular motion and wiped off with a clean cloth.

For deeper scratches, a diamond polishing pad can be used. The pad should be attached to a variable speed polisher and used at a slow speed to avoid damaging the surface further. The pad should be moved in a circular motion, using water as a lubricant.

Step 4: Filling Cracks and Chips: If there are cracks or chips in the surface, they should be filled using an epoxy resin. The resin should be mixed according to the manufacturer's instructions and applied to the damaged area. After the resin has set, it can be sanded down to the level of the surrounding surface.

Recalibrating the accuracy of Precision Granite:

Step 1: Checking the Accuracy: Before recalibrating the precision granite, it is important to check its current accuracy. This can be done using a precision instrument such as a laser interferometer or gauge blocks.

Step 2: Identifying the Problem: If the accuracy is found to be off, the next step is to identify the problem. This may involve inspecting the surface for damage, checking the alignment of the machine, or checking the accuracy of the measuring instruments.

Step 3: Adjusting the Surface: If the surface of the precision granite is found to be uneven, it can be adjusted using a process known as lapping. Lapping involves rubbing the surface of the granite with a fine abrasive to remove high spots and create a flat surface.

Step 4: Checking the Alignment: If the problem is found to be with the machine's alignment, it should be adjusted to ensure that it is parallel to the surface of the precision granite. This can be done using precision shims or adjustment screws.

Step 5: Recalibrating the Instruments: Once the precision granite is repaired and accurate, it is important to recalibrate the measuring instruments used with it. This may involve adjusting the zero point, calibrating the scales, or replacing worn components.

In conclusion, precision granite is a valuable material that requires careful maintenance to ensure its accuracy and durability. By following the steps outlined in this article, you can repair the appearance of damaged precision granite and recalibrate its accuracy to ensure that it remains a reliable tool in your industry.

Post time: Oct-09-2023